Dyeing method of disperse dyestuff with special methylsiloxane as medium

A technology of methyl siloxane and disperse dyes, applied in dyeing, textile and papermaking, etc., can solve the problems of high printing and dyeing wastewater, toxicity and safety, large amount of disperse dyes, etc., to reduce wastewater discharge and achieve good stability. , the effect of good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

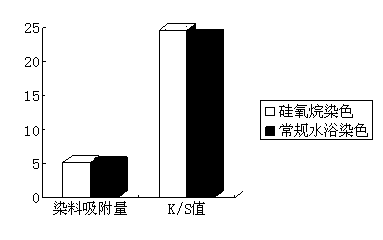

Embodiment 1

[0031] The dyeing method of disperse dyes with special methyl siloxane as medium, the method is as follows:

[0032] (1) Scouring treatment of polyester fabric:

[0033] The polyester fabric is subjected to scouring treatment, and the treatment conditions are: fabric weight 500g; detergent 2g / L; alkali 2g / L, liquor ratio 1:30; temperature 90°C, time 40min.

[0034] (2) Add a certain amount of pure disperse dyes to siloxane according to the dyeing requirements, keep warm at 60°C for 20 minutes, add the fabric to be dyed and a certain amount of water, and dye in the jigger. The dyeing process conditions are as follows:

[0035] Dye at room temperature first, heat up to 90°C within 30 minutes, heat up to 130°C at a rate of 1°C / min and keep warm for 60 minutes, then cool down to 60°C at a rate of 1.5°C / min for drying, remove floating color, and finally wash with water ,drying.

[0037] Disperse dyes (C.I. Disperse Blue 183): 0.7%(o.w.f);

[0038] Fa...

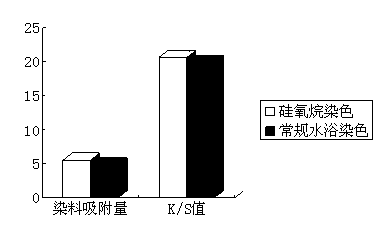

Embodiment 2

[0048] (1) Scouring treatment of polyester fabric:

[0049] The polyester fabric is subjected to scouring treatment, and the treatment conditions are: fabric weight 500g; detergent 2g / L; alkali 2g / L, liquor ratio 1:30; temperature 90°C, time 40min.

[0050](2) According to the dyeing requirements, take a certain amount of pure disperse dyes and add them to siloxane, keep them warm at 60°C for 20 minutes, add the fabric to be dyed and a certain amount of water, and carry out dyeing in an overflow dyeing machine. The dyeing process conditions are as follows :

[0051] Dye at room temperature first, heat up to 90°C within 30 minutes, heat up to 130°C at a rate of 1°C / min and keep warm for 60 minutes, then cool down to 60°C at a rate of 1.5°C / min for drying, remove floating color, and finally wash with water ,drying.

[0053] Disperse dyes (C.I. Disperse Orange 29): 0.7% (o.w.f);

[0054] Fabric weight: 500g;

[0055] Bath ratio: 1:10;

[0056] The vo...

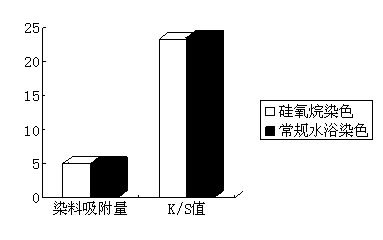

Embodiment 3

[0064] (1) Scouring treatment of polyester fabric:

[0065] The polyester fabric is subjected to scouring treatment, and the treatment conditions are: fabric weight 500g; detergent 2g / L; alkali 2g / L, liquor ratio 1:30; temperature 90°C, time 40min.

[0066] (2) According to the dyeing requirements, take a certain amount of pure disperse dyes and add them to siloxane, keep them warm at 60°C for 20 minutes, add the fabric to be dyed and a certain amount of water, and carry out dyeing in a jet dyeing machine. The dyeing process conditions are as follows:

[0067] Dye at room temperature first, heat up to 90°C within 30 minutes, heat up to 130°C at a rate of 1°C / min and keep warm for 60 minutes, then cool down to 60°C at a rate of 1.5°C / min for drying, remove floating color, and finally wash with water ,drying.

[0069] Disperse dyes (C.I. Disperse Orange 79 # :1): 0.7% (o.w.f);

[0070] Fabric weight: 500g;

[0071] Bath ratio: 1:10;

[0072] The vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com