Substrate supporting structure and reaction chamber containing the same

A support structure and substrate technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems that the substrate support plate is easy to fly out and the rotation is unstable, so as to achieve stable positional relationship and improve The effect of uniformity of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

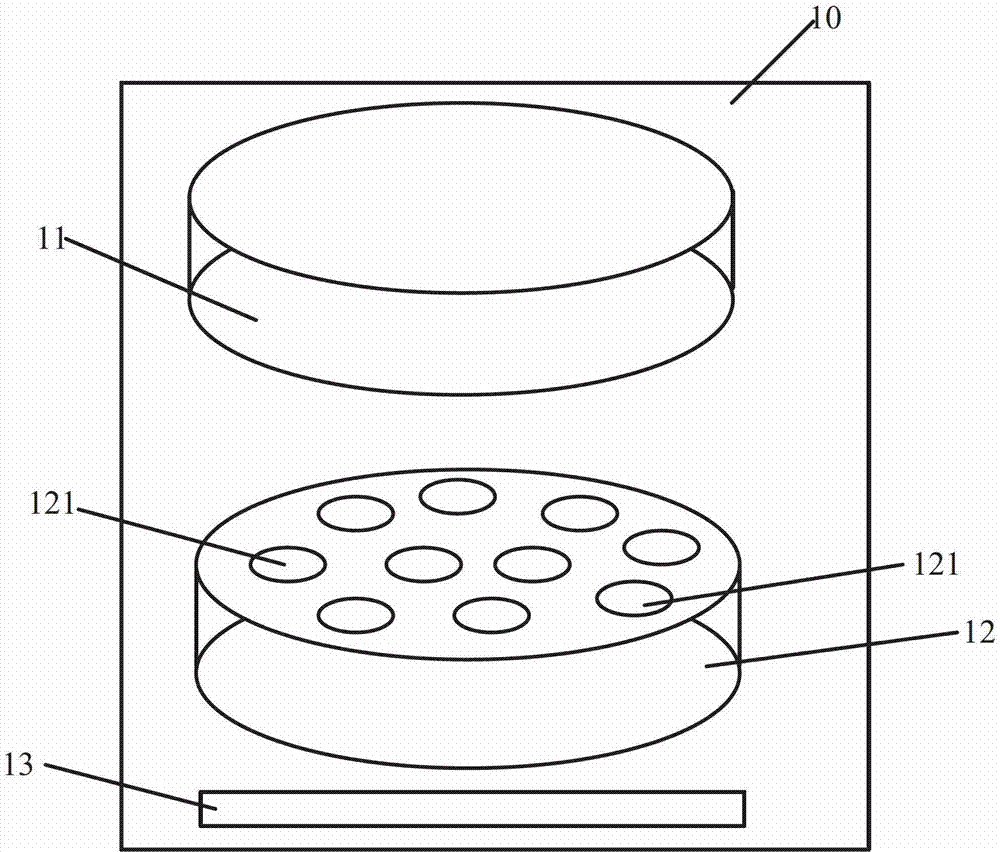

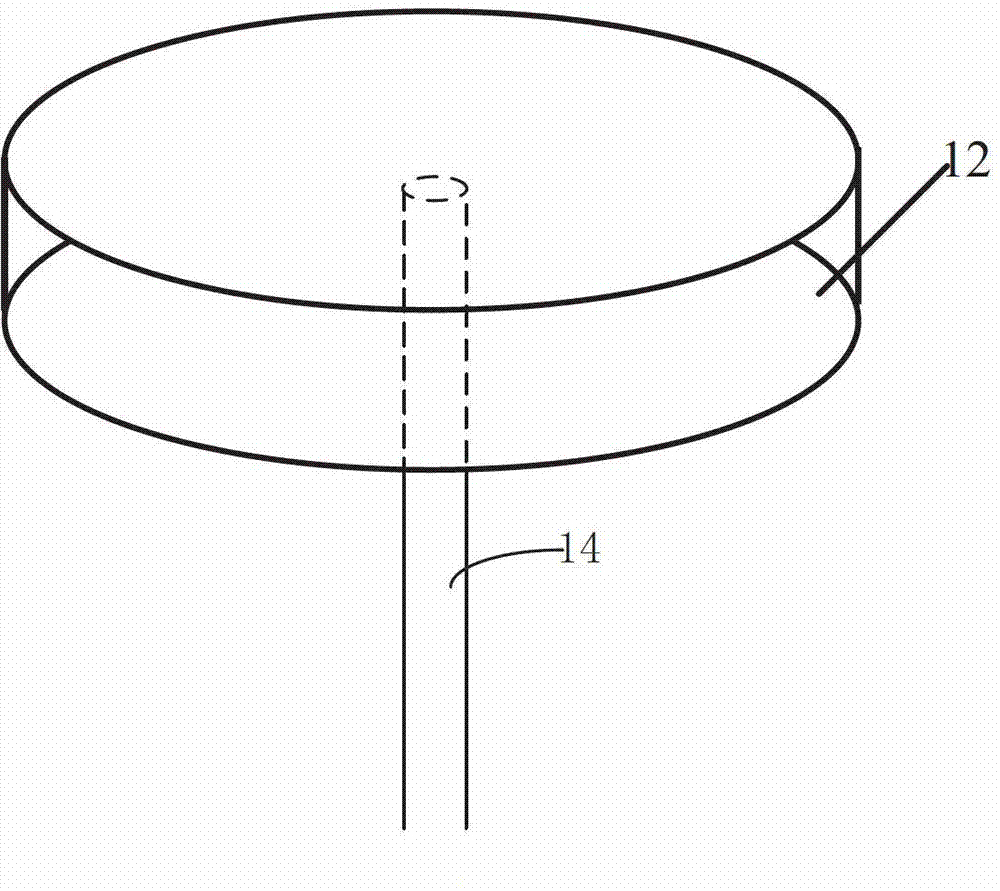

[0037] The existing substrate support disk is unstable during the rotation process and is easy to fly out. According to the inventor’s research, it is found that since the supporting column is usually arranged under the existing substrate supporting plate, the supporting column is used to drive the substrate supporting plate to rotate. Specifically, please combine figure 2 The schematic diagram of the structure of the prior art substrate support plate and its support column is shown. There is a support column 14 below the substrate support tray 12, and the area of the support column 14 is smaller than the area of the back surface of the substrate support tray 12. The support column 14 fixes the substrate support disk 12, and the substrate support disk 12 can rotate under the drive of the substrate support disk 14. The rotation surrounds the center of the contact surface of the substrate support disk 12 and the support column 14. Performed vertically. During the rotation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com