Three-roll welding equipment and welding method for adult incontinence pants and baby pull-up pants production line

A technology of baby pull-up pants and welding equipment, which is applied in the field of adult incontinence pants, can solve the problems of affecting the use function and appearance quality, affecting the production speed of the main machine, and local welding is not firm, so as to achieve excellent heat insulation effect, save material cost, Easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

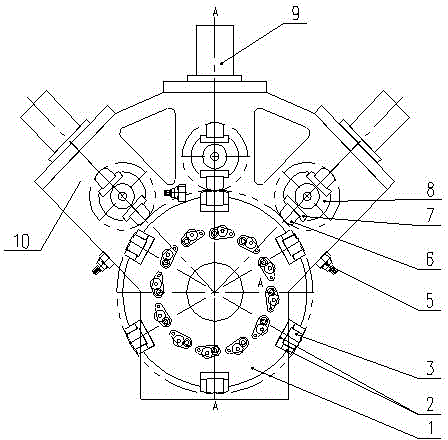

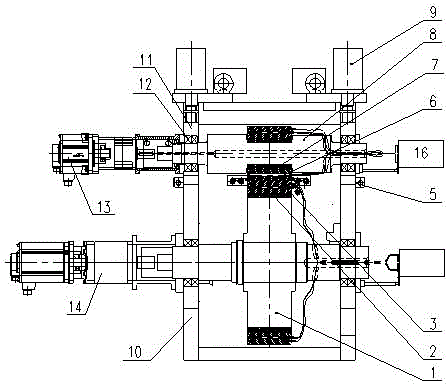

[0014] Embodiment 1: with reference to attached Figure 1-6 . A three-roll welding equipment for adult incontinence trousers and baby pull-up trousers production line, including a PLC controller, the two ends of the lower roller 1 are in rotation with the lower part of the knife box plate 10, and the roller surface of the lower roller 1 is equidistantly equipped with six lower heating module strips 3. The lower roller 1 is driven by the lower servo drive synchronous control mechanism 14 through the coupling. The shaft core of the lower roller 1 has a wire groove and the wire groove is built with a power line 17. The output end of the power wire is electrically heated for the lower heating module bar 3. tube power supply, the input end of the power line 17 is connected with the power output end in the rotating collector ring 16 fixed on the knife box plate 10, and the power input end of the rotating collector ring 16 is connected to the power supply; The upper roller 8 and the...

Embodiment 2

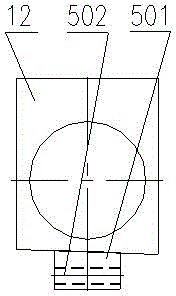

[0015] Embodiment 2: On the basis of the above embodiment 1, the hot-pressed bar surface of the upper heating module bar 6 is provided with a hot-pressed tooth surface 601 . The hot-pressed strip surface of the lower heating module bar 3 is a smooth surface and is provided with a hot-pressed tooth surface 601 for heat-compression fit with the hot-pressed strip surface of the upper heating module bar 6 .

Embodiment 3

[0016] Embodiment 3: On the basis of Embodiment 1 or 2 above, the pattern of the upper hot-pressed tooth surface 301 or the lower hot-pressed tooth surface 701 is straight teeth, helical teeth, V-shaped teeth, or wave-shaped teeth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com