Automatic stamping production line for electric appliance casings

A production line and automatic technology, applied in the direction of electrical program control, feeding device, positioning device, etc., can solve the problems of low safety factor, low efficiency, and high labor intensity of workers, and achieve compact structure, high efficiency, and low labor intensity of workers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

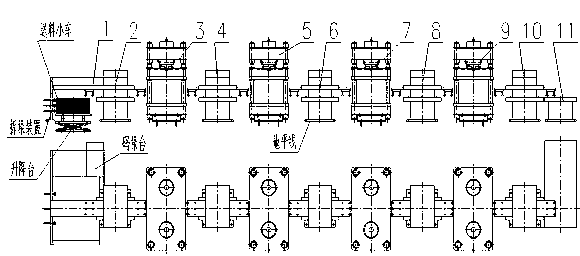

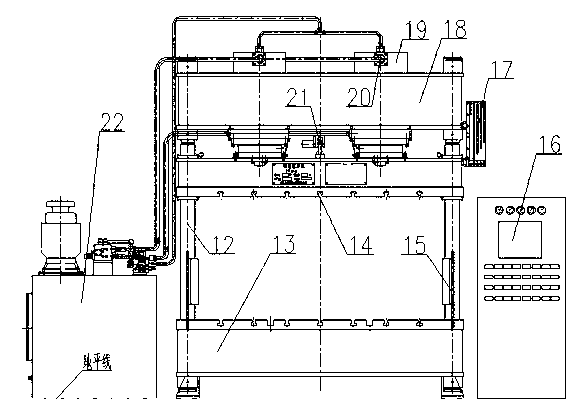

[0021] See figure 1 , the production line is generally composed of 4 high-quality CNC hydraulic machines, 6 sets of manipulators, 5 sets of centering platforms, 1 set of conveyors, 1 set of unstacking devices, 2 sets of feeding trolleys, 1 set of lifting positioning devices, and 1 set of multi-material palletizing platforms composition. The entire stamping production line can automatically complete destacking, loading, 1 stamping / stretching forming, 2 stamping / stretching forming, 3 stamping / stretching forming, 4 stamping / stretching forming, and 4 midway retrieving , positioning, feeding, discharging and other production processes.

[0022] The automatic production line adopts 4 CNC stamping / stretching hydraulic machines to stamp / stretch the shell sheet, and 1 set of unstacking manipulators will dismantle the off-line blanks one by one and send them to the centering platform 31 for positioning, and the loading manipulator Send the blanks on the centering station 31 to the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com