Artificial knee-joint thighbone

A technology for artificial knee joint and femur, applied in the field of prosthesis, can solve problems such as unresolved pain, and achieve the effects of reducing the incidence, reducing the amount of osteotomy, and increasing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

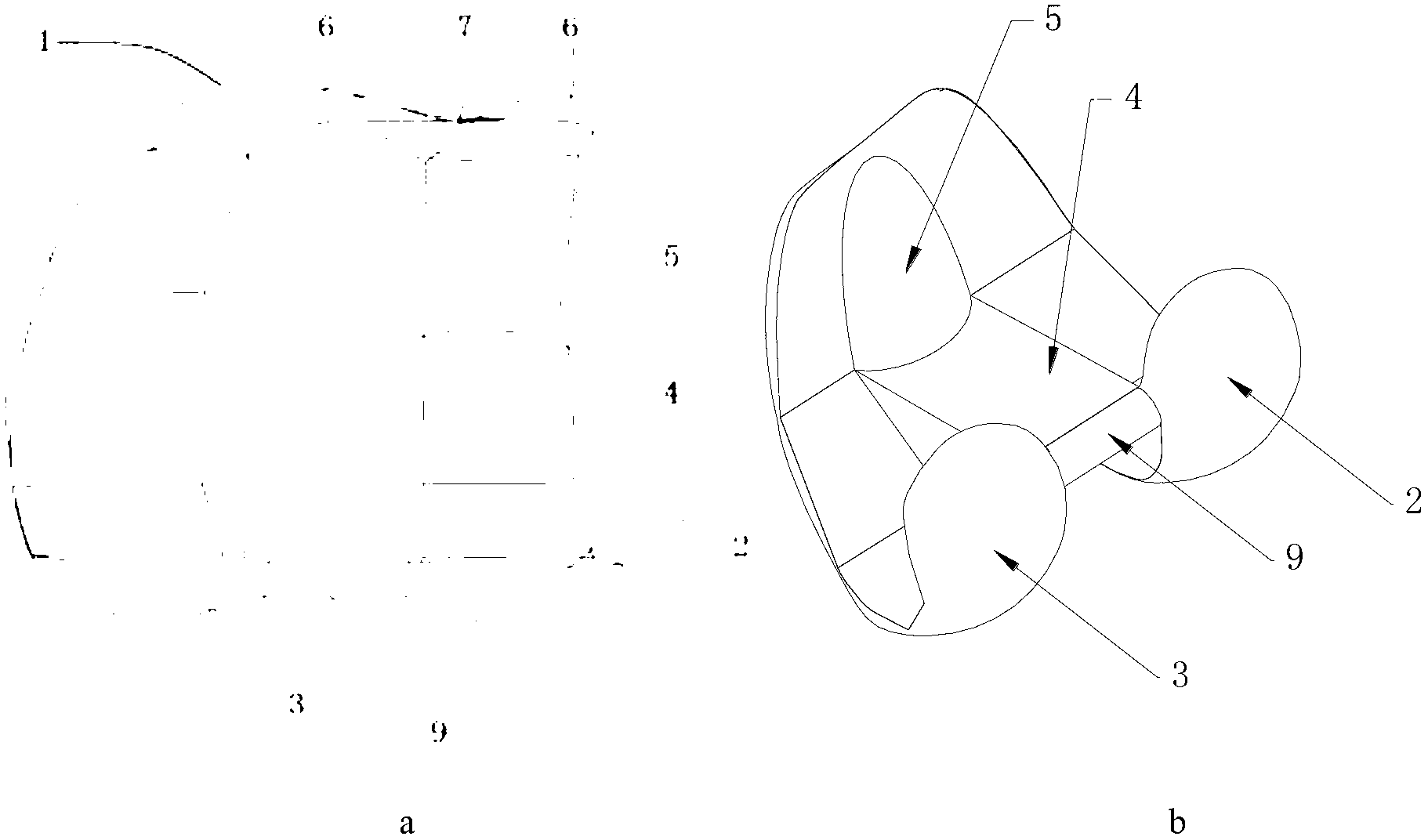

[0026] Such as figure 1 a and figure 1 As shown in b, this embodiment includes: the anterior condyle 1, the articular surface of the first femur 2, the articular surface of the second femur 3 and the insertion block 4, wherein: the articular surface 2 of the first femur and the articular surface 3 of the second femur Arranged side by side and connected with the anterior condyle 1 on the other side to form a U-shaped structure, an insertion block 4 is provided between the anterior condyle 1 and the articular surfaces 2 and 3 of the first and second femurs, and the insertion block 4 One end surface is located in the middle of the anterior condyle 1, the other end is located in the middle of the first and second femoral articular surfaces 2, 3, and the inner side of the anterior condyle 1 is provided with a strength increasing component 5.

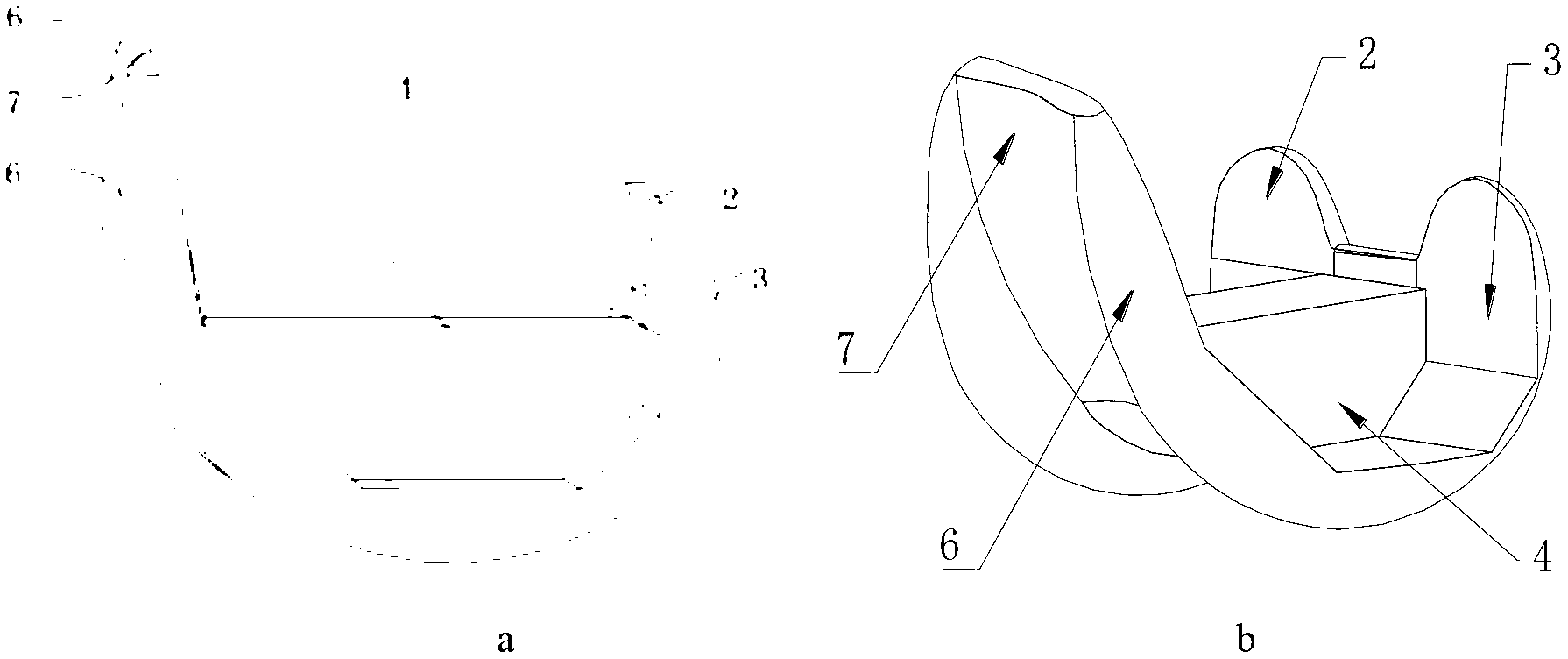

[0027] Such as image 3 , Figure 4 As shown, the structure of the strength increasing part 5 is a semi-conical structure, the bottom dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com