Transformer oil paper insulation state testing device and control method based on return voltage method

A technology of recovery voltage and state testing, applied in the direction of testing dielectric strength, etc., can solve the problems of large error, complicated operation, unsuitable for on-site use, etc., achieve high accuracy, broad application prospects, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

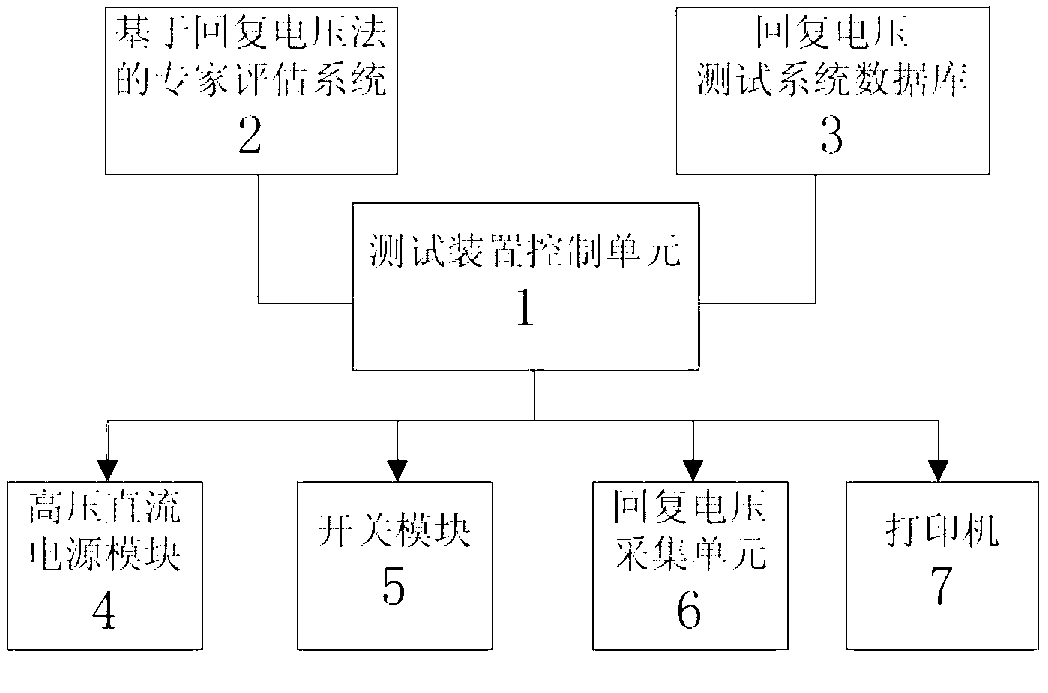

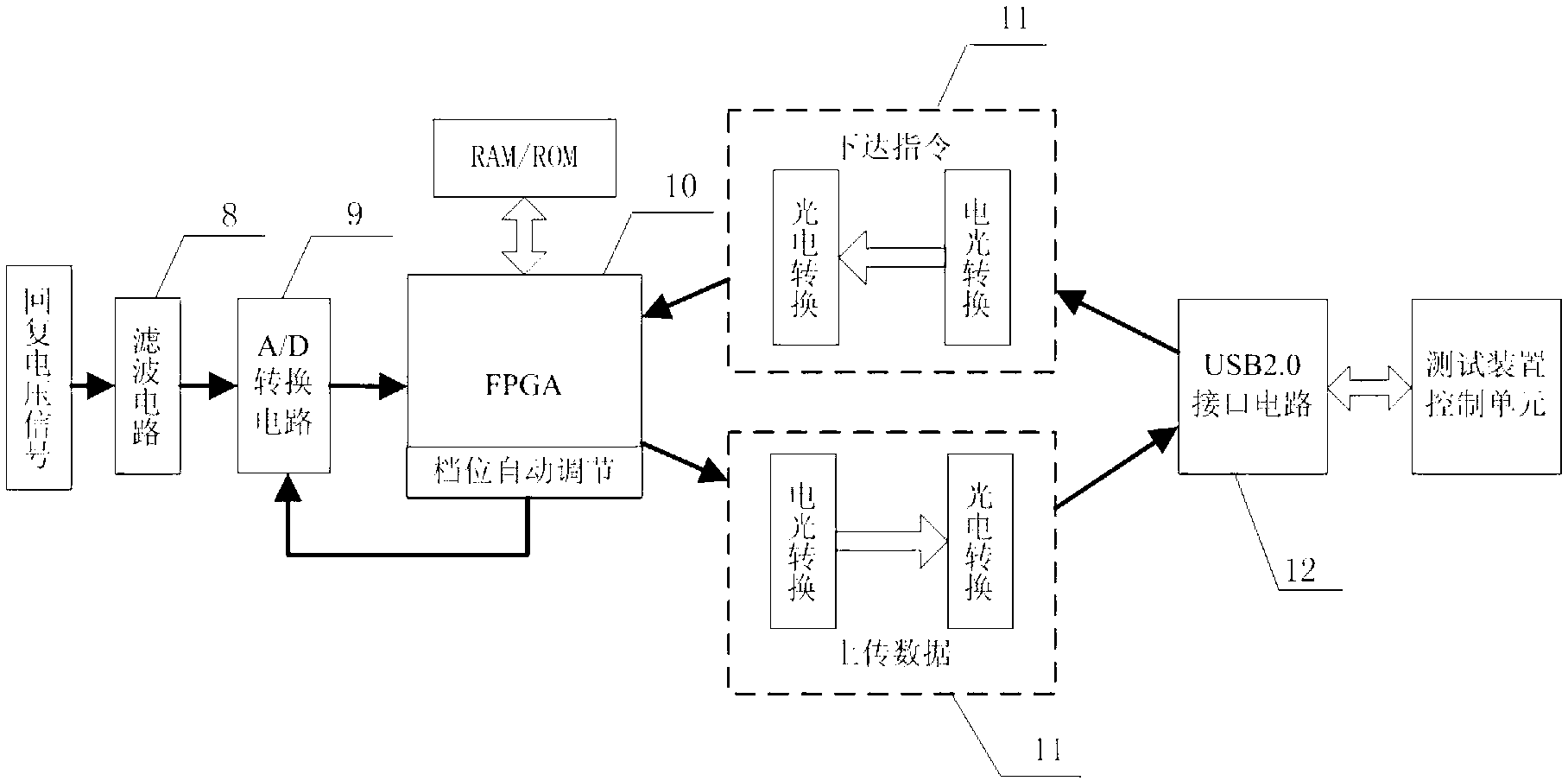

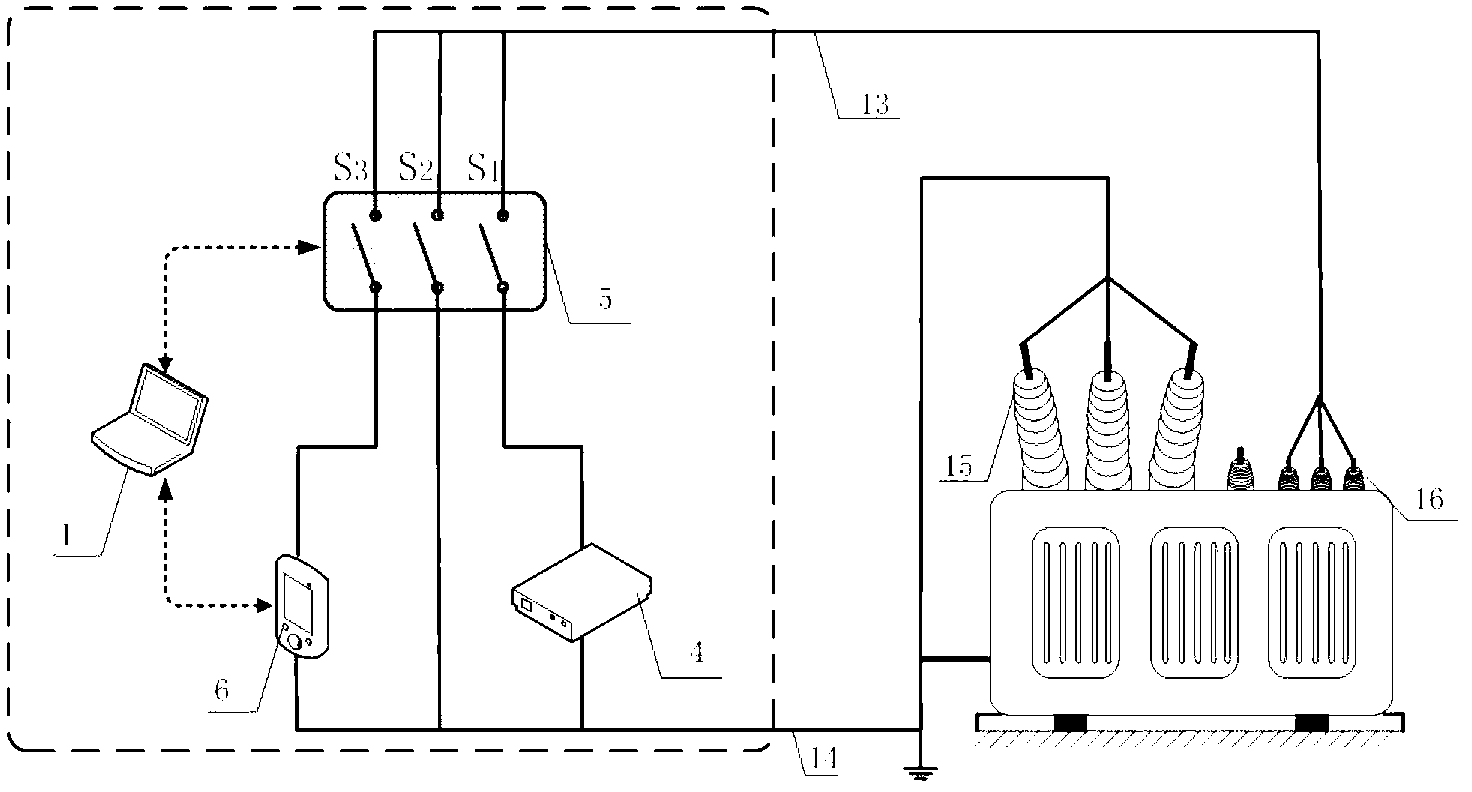

Method used

Image

Examples

Embodiment 1

[0035] A transformer factory used the present invention to test a transformer with a capacity of 150MVA that was put into operation in 1987 before (test product 1) and after transformation (test product 2). Set the test voltage U c =2000V, charging time T c =500s, the charging and discharging time is longer than T c / T d =2. The test results are shown in Table 1.

[0036] Table 1 Test results

[0037]

[0038] Note: U rmax — Maximum recovery voltage, unit: V

[0039] S i — The initial slope of the recovery voltage, unit: V / s

[0040] t cdom — central time constant, unit: s

Embodiment 2

[0042] A residential area implemented a power distribution equipment renovation project, shut down and dismantled 2 transformers, both with a capacity of 630kVA, put into operation in 1987 and 2001, and numbered 1# and 2# respectively. The two transformers are tested respectively by using the present invention. Set charging time U c =1000V, charging time T c =200s, the charging and discharging time is longer than T c / T d =2. The test results are shown in Table 2.

[0043] Table 2 Test results

[0044] Transformer number

u rmax (V)

S i (V / s)

t cdom (s)

Insulation state

1#

34.6

37.8

12.4

Insulation aging is serious

2#

9.3

12.5

38.1

Good insulation performance

[0045] From the test results in Table 1, it can be seen that the U rmax and S i Greater than sample 2, t cdom smaller than sample 2.

[0046] The test results show that: the insulation effect of sample 1 is very poor, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com