Detecting method of outer anti-corrosion layer of buried fuel gas steel pipeline

A detection method and anti-corrosion layer technology, applied in the direction of material magnetic variables, etc., can solve the problems of many factors, large errors, and inability to determine the size and location of defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] 1. Test content

[0023] (1) Detection of buried depth and direction of pipelines;

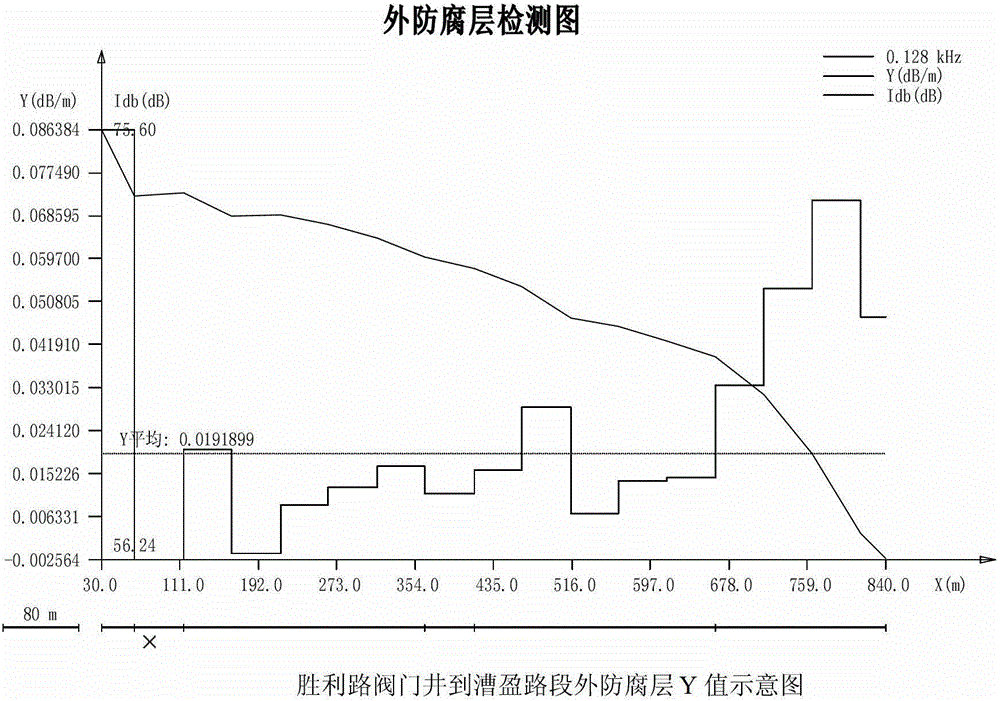

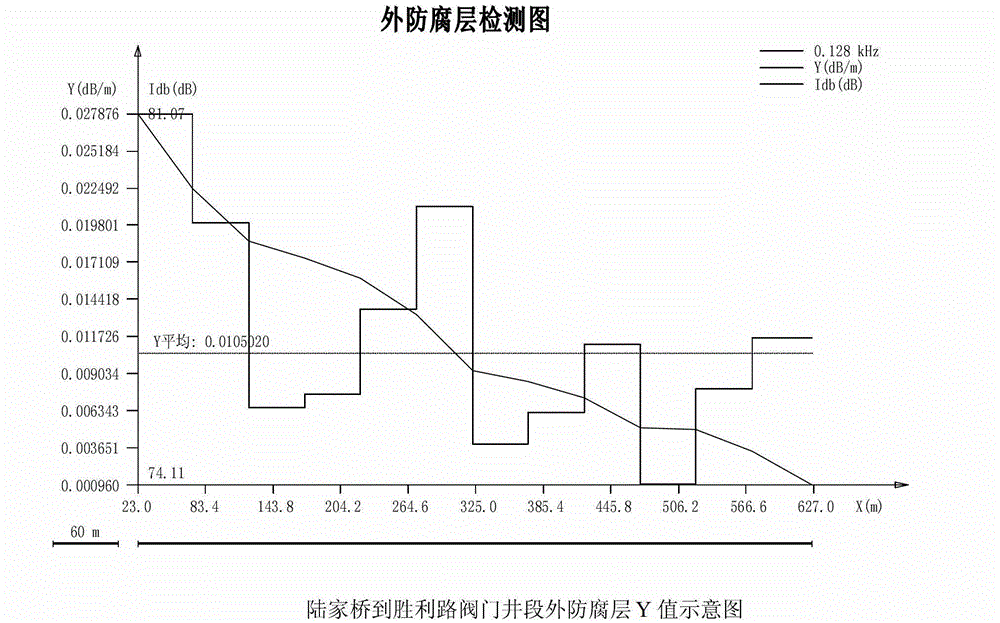

[0024] (2) Performance testing of the outer anti-corrosion layer;

[0025] (3) Location detection of damaged points of the outer anti-corrosion layer.

[0026] 2. Test equipment

[0027] The instruments and quantities prepared for this test are shown in Table 5.1.1.

[0028] Table 5.1.1 Instrument and Equipment Table

[0029] instrument

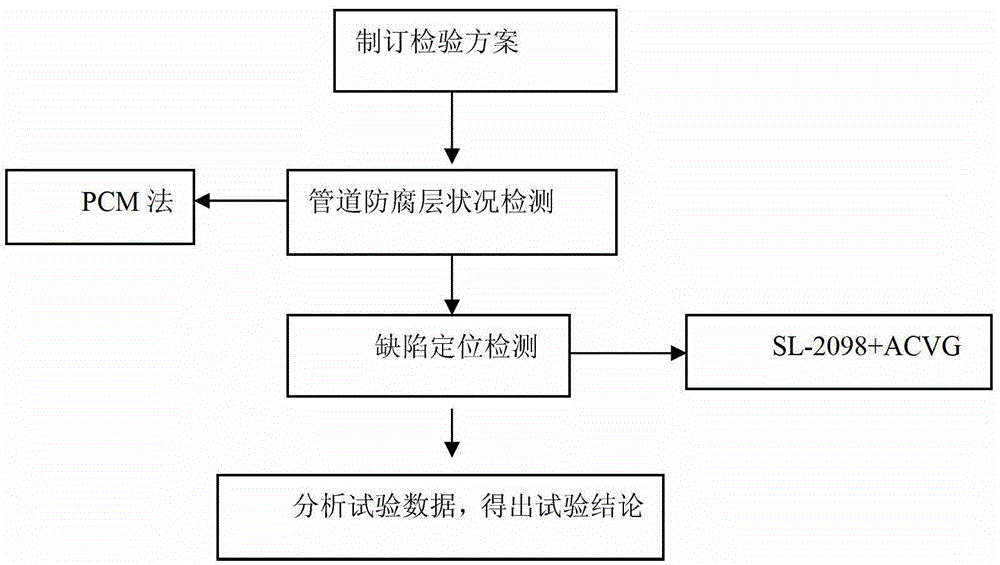

[0030] 3. Determine the test method and program

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com