Framed bent device for wind tunnel flow field

A technology of flow field testing and wind tunnel, which is applied in the field of structural wind engineering, can solve problems affecting the accuracy and efficiency of flow field debugging, and achieve the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

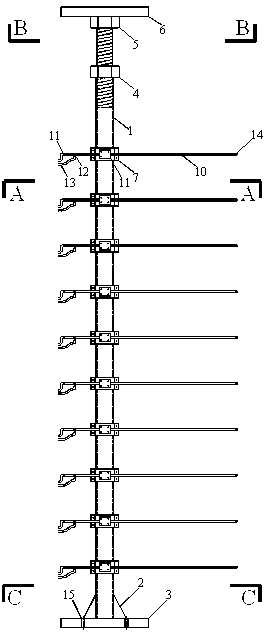

[0023] Now take the test of ten measuring points in the vertical flow field of the wind tunnel as an example to illustrate the application method of the present invention.

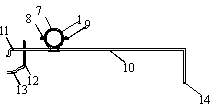

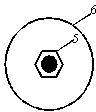

[0024] Such as Figure 5 As shown, firstly, the circular steel plate 3 of the device is placed downwards at the designated position of the wind tunnel test section, and the circular steel plate 3 is fixed on the bottom plate 16 of the test section with screws, and the head of the screw 5 is turned with a wrench, and the other circular steel plate 3 is The steel plate 6 presses against the top plate 17 of the test section, installs ten wind tunnel flow field test components with the same structure on the round steel pipe 1, and ensures that the distance between the wind tunnel flow field test components meets the requirements of the flow field test, and ensures that all The probes 14 of the pitot tubes 10 are all facing the incoming flow direction of the wind, and the distance from the center of the probes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com