Improved shock attenuation device

A technology of shock absorbing device and shell, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of noise, oil leakage, pollution of other parts, etc., to prolong the service life, improve the Using the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

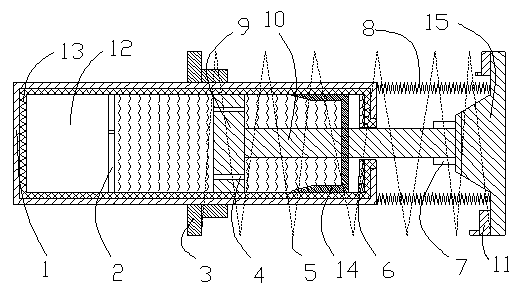

[0009] Such as figure 1 As shown, an improved damping device includes a damper housing, a piston seat, a spring seat 2 welded on the damper housing, a piston rod fixedly installed on the piston seat, a spring seat 1, a spring seat 1 and A return spring is installed between the two spring seats, a piston head is installed above the piston rod, a damping hole is provided on the piston head, a movable baffle is provided between the upper end of the housing and the piston head, and a movable baffle is provided on the baffle. The gas damping hole is above the air cavity, and the elastic layer is embedded in the damper shell. The two sides of the piston head cooperate with the elastic layer, and the mountain-shaped piece is fixedly installed on the piston rod. There are slopes on the hills on both sides of the parts. Oil absorption parts, such as sponges, are installed at the connection between the piston rod and the piston seat. The material of the buffer layer is foam products, ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com