Low-pressure prevention alarm device for air compressor

A technology of air compressor and alarm device, applied in mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve the problem that affects the quality of sintered products, the air compressor cannot be detected in time, and the controlled state of the air supply equipment cannot be guaranteed. and other problems, to achieve the effect of stabilizing product quality, reducing waste of working hours and reducing product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the scope of the patent application of the present invention and the contents of the description still belong to the patent of the present invention covered.

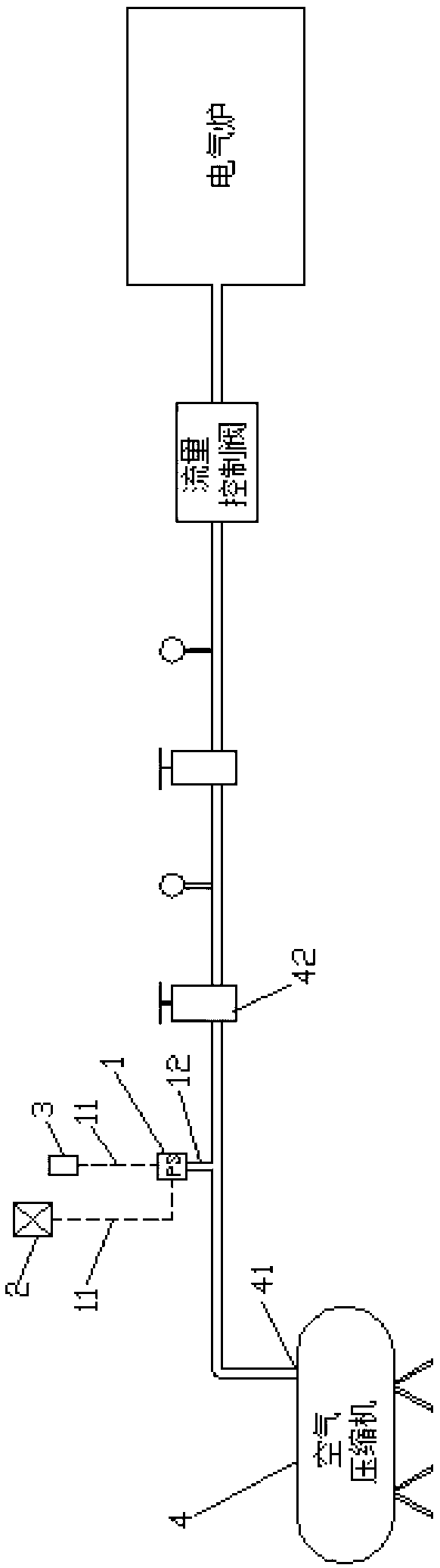

[0015] like figure 1 As shown, a low-pressure prevention alarm device for an air compressor includes a pressure switch 1 and an alarm device 2. The pressure switch is electrically connected to the alarm device 2 and a 220V power supply 3 through wires 11 respectively, and the pressure measuring head of the pressure switch is connected to the pipeline 12. It is installed between the air outlet 41 of the air compressor 4 and the pressure reducing valve 42 .

[0016] Start the air compressor to make the air pressure reach about 7kgf / cm3.

[0017] Adjust and set the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com