Lift-resistance type vertical-axis wind generator blade

A wind turbine, vertical axis technology, applied in wind turbines, wind turbines at right angles to the wind direction, motors, etc., can solve the problem of low blade tip speed ratio and wind energy conversion rate, high starting wind speed of blades, and low torque, which is difficult to start. and other problems, to achieve the effect of improving wind energy conversion rate, large torque, and high tip speed ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

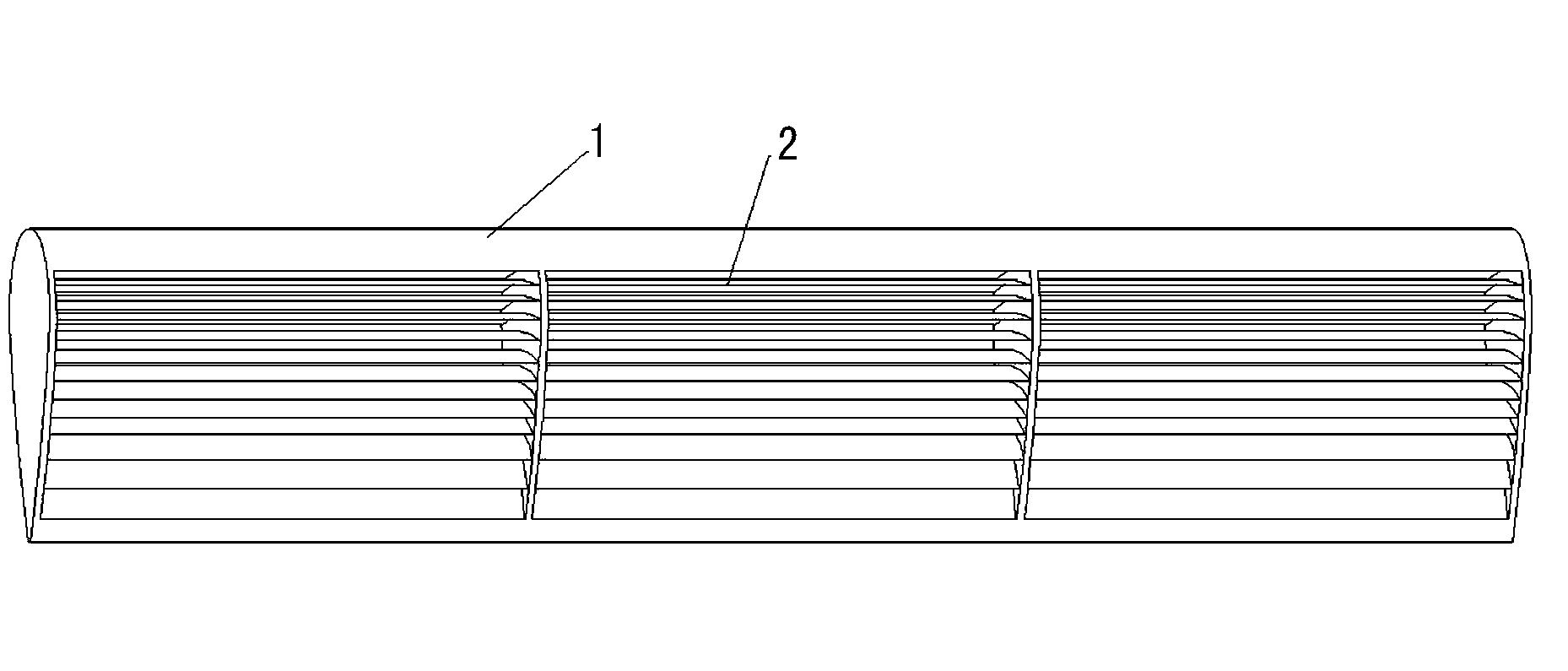

[0010] as attached figure 1 , the blade of the lift-drag type vertical axis wind power generator includes an airfoil blade 1, and the blade 1 is vertically installed. Airflow passages 2 are arranged on the cross section of the blade 1 , and the airflow passages 2 are arranged in multiple sections in the longitudinal direction of the blade 1 . The air flow passage 2 of the accompanying drawing embodiment is arranged in three sections.

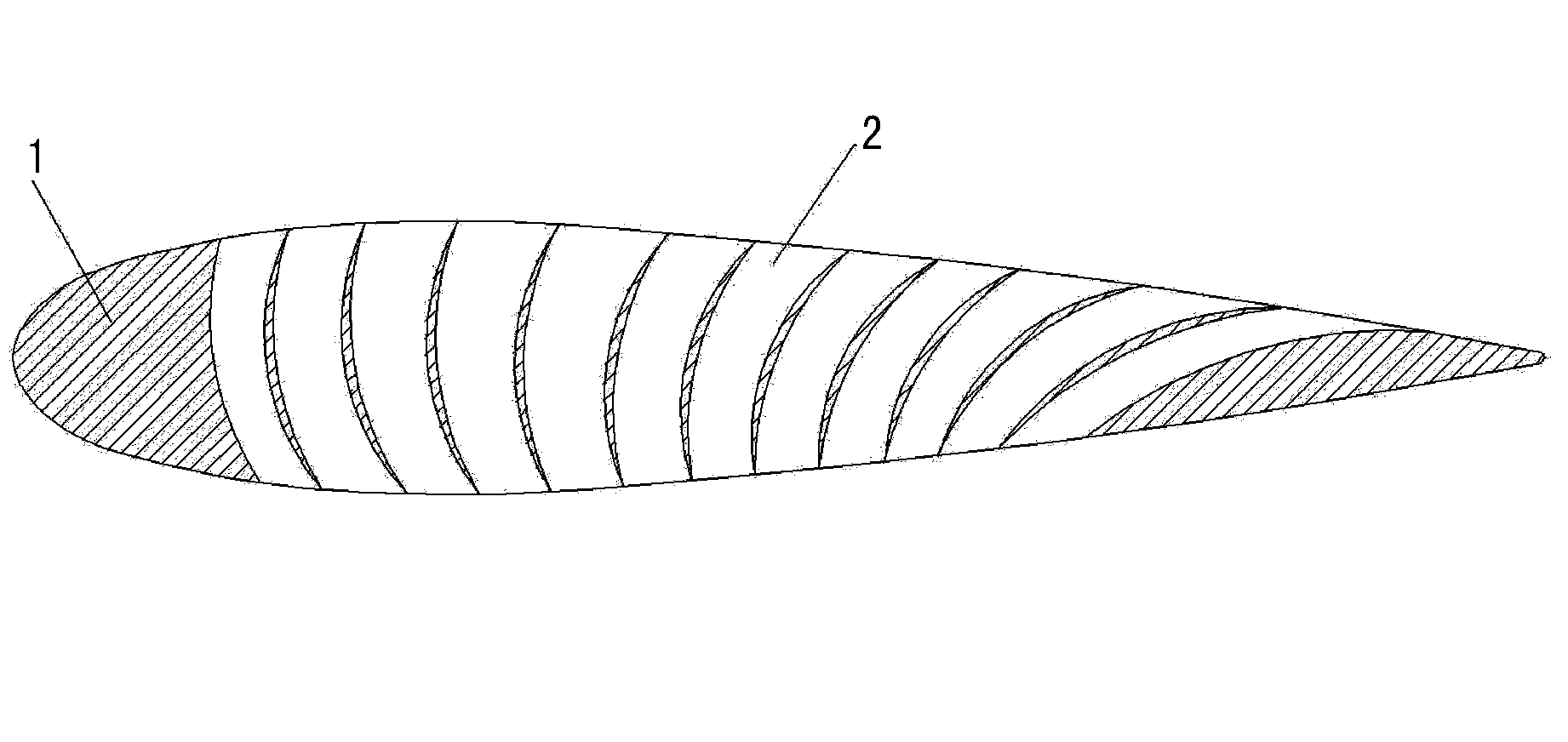

[0011] as attached figure 2 , the airflow channel 2 is arc-shaped in the transverse section of the blade, the channel opening of the airflow channel 2 is placed on both sides of the blade 1, the convex arc surface of the airflow channel 2 faces the leading edge of the blade 1, the airflow channel The concave arc surface of 2 faces the trailing edge of blade 1.

[0012] as attached figure 2 , when the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com