Casing pipe dislocation horizontal well correction and repair method and dedicated integration tools of casing pipe dislocation horizontal well correction and repair

A repair method and technology for horizontal wells, which are used in earth-moving drilling, wellbore/well components, etc., can solve the problems of correcting and repairing the staggered casing in the horizontal section, shortening time and steps, avoiding secondary damage, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Next, with reference to the drawings of the description, the method for correcting and repairing a horizontal well with casing dislocation and its special integrated tool of the present invention will be described in detail below.

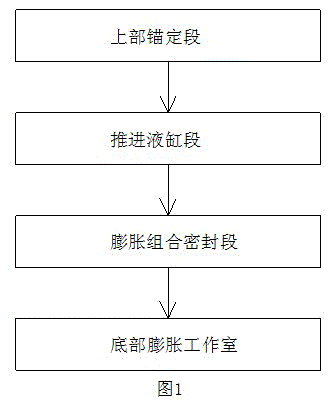

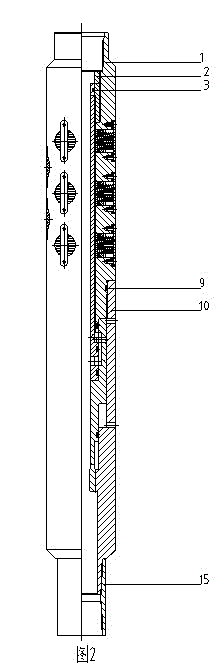

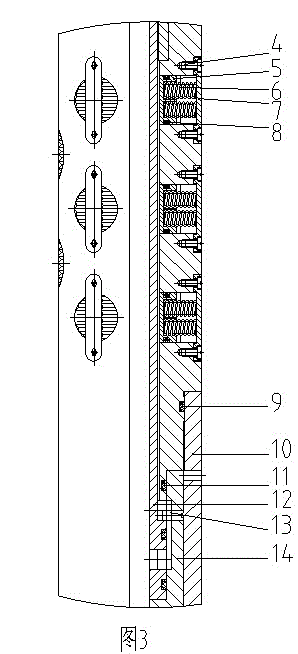

[0027] The special integrated tool for correcting and repairing horizontal wells with casing dislocation, its structure includes four parts: bottom expansion working chamber, expansion combined sealing device, propulsion cylinder device and upper anchoring device connected sequentially from bottom to top. Such as figure 1 shown.

[0028] Such as Image 6 As shown, the structure of the bottom expansion working chamber includes the outermost expansion tube 47 and the straightening head 57 provided at the bottom end of the expansion tube. The upper central tube 45 and the lower central tube 49 connected together up and down are arranged inside the expansion tube. ; The lower central tube is covered with a combined expansion head top sleeve 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com