Automatic placing device for reflective cones

A technology of placing device and reflective cone, which is applied in the directions of roads, road signs, traffic signals, etc., can solve the problems of high labor intensity, low work efficiency, and harsh working environment for workers, so as to achieve simple and flexible operation, and the placement distance can be adjusted. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

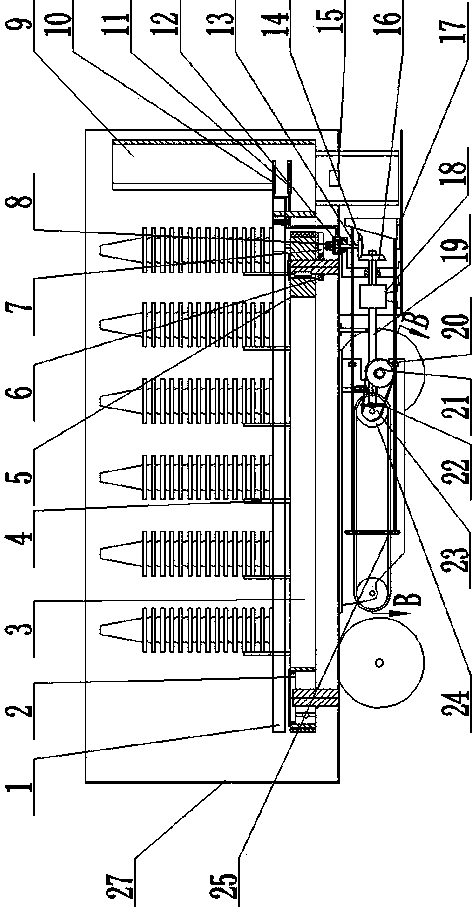

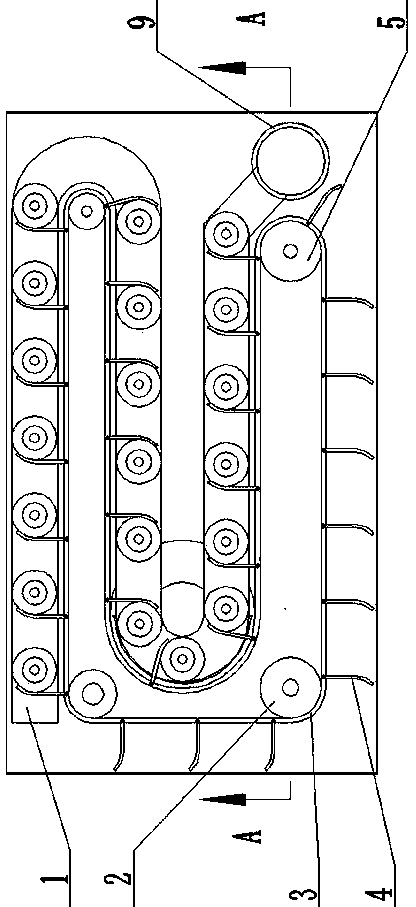

[0017] like Figure 1~5 As shown, a reflective cone automatic placement device includes a feeding device arranged on the car body 27, a material storage cylinder, a material distribution device and a material pushing device.

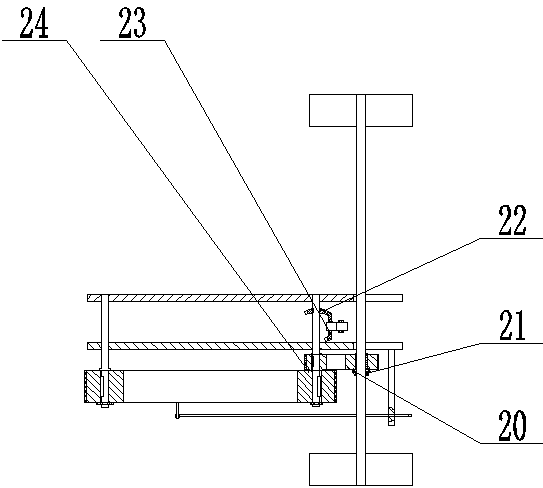

[0018] The feeding device is mainly composed of a guide rail 1, a conveyor belt 3 and a baffle 4, the conveyor belt 3 is arranged around the guide rail 1, and a baffle 4 is installed at a certain distance on the conveyor belt 3, and the distance between two adjacent baffles is equal; The feeding device is mainly composed of a secondary gearbox 18, a bevel gear, a cam 12, a left distributing rod 10, and a right distributing rod 11; Bearing pin 25 and push rod 17 form.

[0019] The speed-increasing belt transmission mechanism comprises a sliding key clutch and a speed-increasing belt pulley arranged on the rear axle of the wheel, and the speed-increasing belt pulley is connected with the driving wheel of a constant-speed belt transmission mechanism. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com