Long-strip boat feeding device and method

A supply device and strip-shaped technology, applied in packaging and other directions, can solve the problems of high production cost and many hidden safety hazards, and achieve the effects of small operating noise, reduced labor intensity, and simple and easy on-site installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

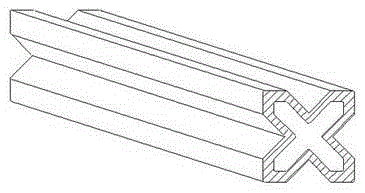

[0098] In the first embodiment, the elongated boat supply device of the present invention is further described by taking the elongated boat as an example of the X boat.

[0099] image 3 It is a schematic diagram of the X boat supply device of the first embodiment of the present invention, which includes: PLC (programmable logic controller, the same below), a feed bin (the feed bin in this embodiment adopts the first feed bin A, the second feed bin The double bin form of warehouse B is used as an example), conveyor belt (the bin in this embodiment is illustrated by the two-stage conveyor belt form of feeding boat belt 24 and material receiving belt 29), motor (the motor in this embodiment includes feeding Boat belt motor 25, material receiving belt motor 26).

[0100] Such as image 3 As shown, the first silo A includes: the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com