Automatic blanking and code-printing device for multiple cigarette sample inspection items

A sample and blanking technology, which is applied in the field of sample automatic blanking and coding devices, can solve the problems of complex sorting and inspection, high labor intensity, human error, etc., and achieve the effect of expanding flexibility, improving work efficiency and speed

Active Publication Date: 2013-04-24

ZHENGZHOU TOBACCO RES INST OF CNTC +1

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] The manual preparation method has the following disadvantages: the sample composition plan may not be able to be different from the other two cigarettes in each evaluation sample, and another cigarette of the same cigarette appears randomly; the cigarettes are coded, combined, and bagged manually according to the sample composition plan In the process of ma

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

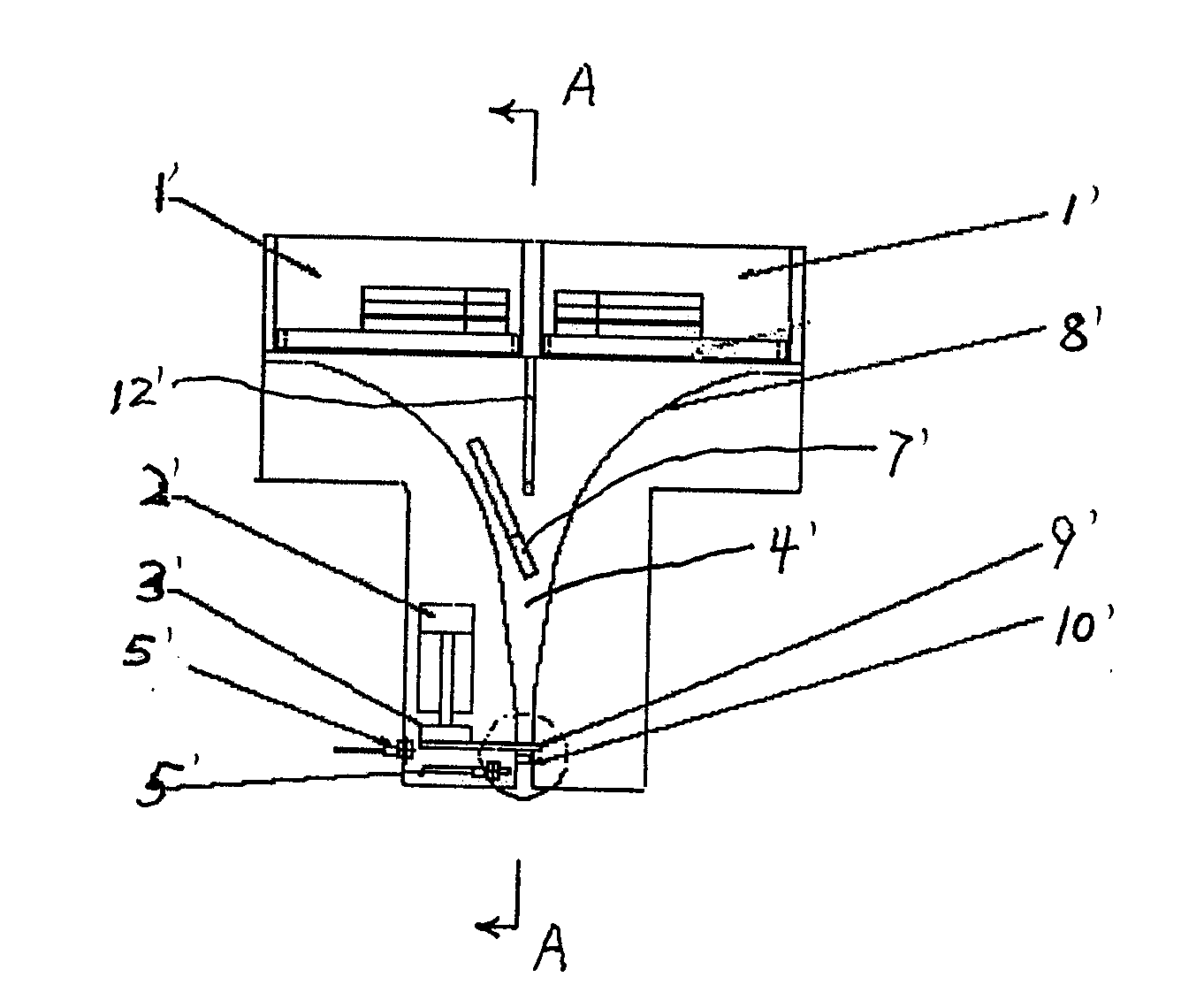

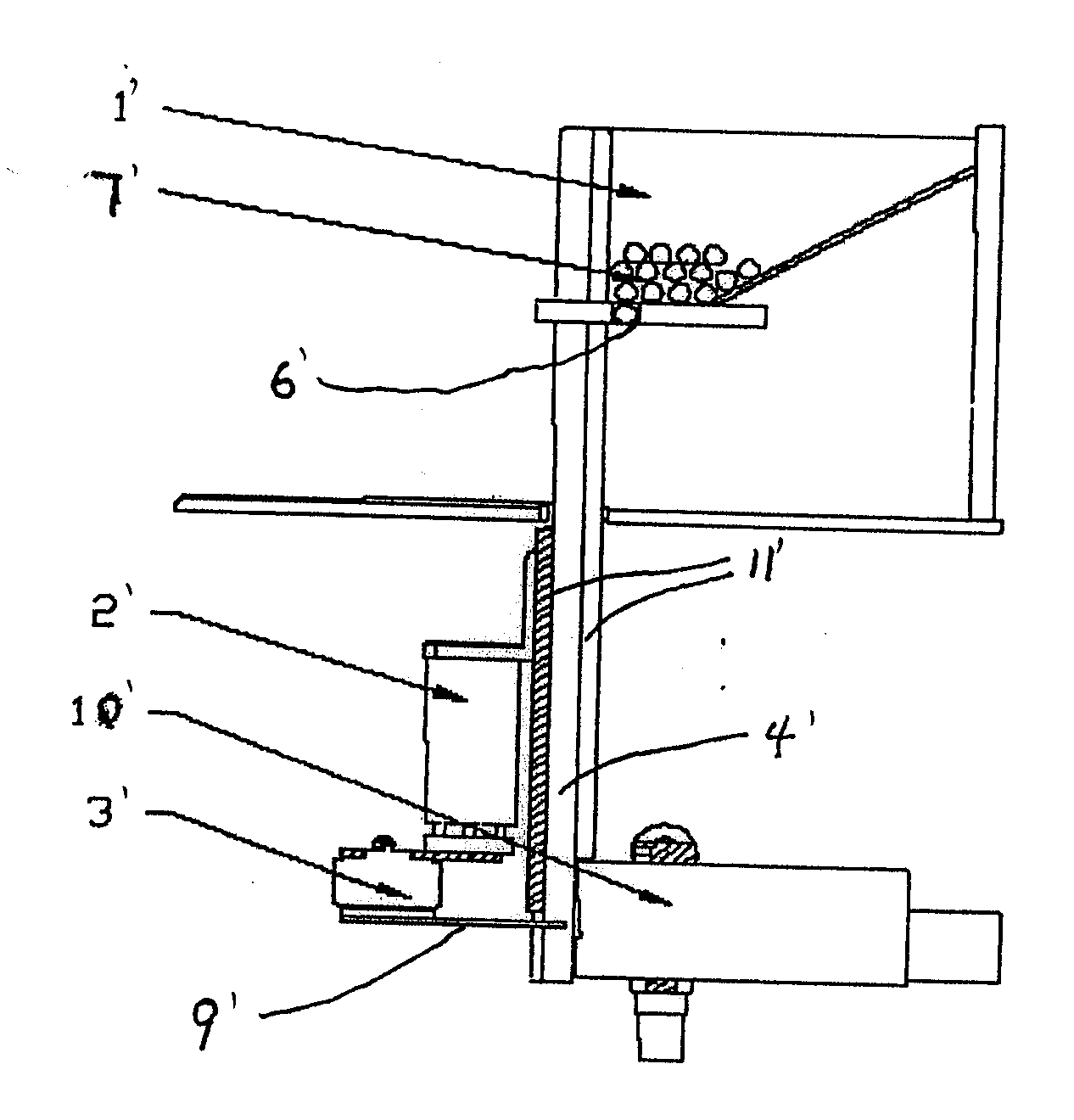

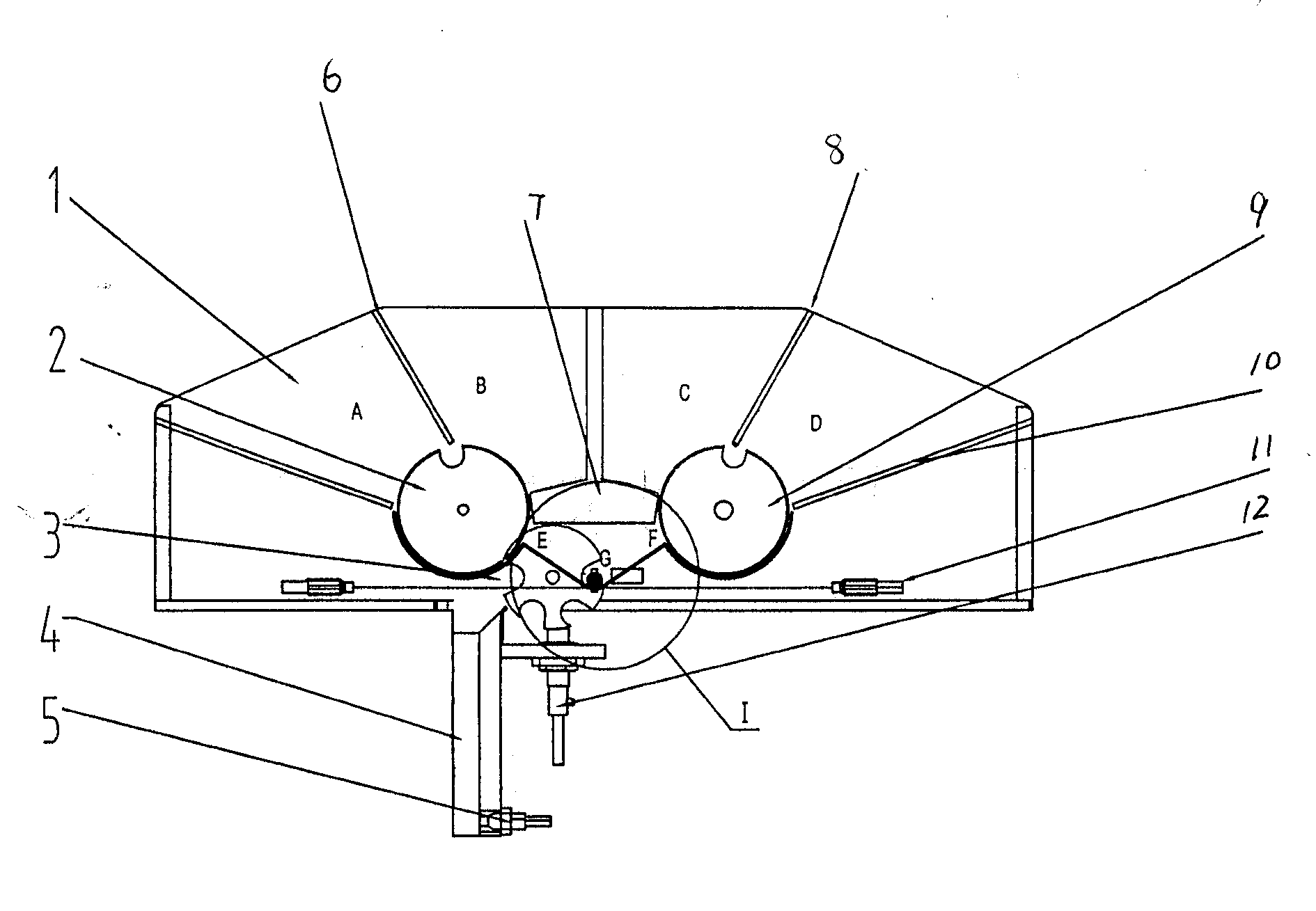

The invention discloses an automatic blanking and code-printing device for multiple cigarette sample inspection items. The automatic sample blanking and code-printing device is characterized in that a blanking and code-printing mechanism consists of a left hopper, a right hopper, a left roller, a right roller, a code spraying roller, a photoelectric detector, a code spraying nozzle and a blanking slideway, wherein the left hopper and the right hopper are used for accommodating cigarette samples; the left roller and the right roller are positioned at the lower part of the left hopper and the right hopper; and the blanking slideway is arranged at the lower part of the code spraying roller. The automatic sample blanking and code-printing device has the advantages that the automatic blanking and code-printing of the samples are realized, so that the human errors are avoided, the labour intensity and the working noise is reduced, and the working efficiency is improved. Compared with the prior art, the equipment has a reasonable and compact structure and is small in size, so that the device can be used for three-point inspection of cigarettes, and also can be used for contrast and sequencing inspection of multiple kinds of cigarettes; and therefore, the device is wide in application range, and high in blanking and code-printing efficiency.

Description

[0001] technical field [0002] The invention relates to the technical field of cigarette evaluation and detection, in particular to a sample automatic blanking and coding device suitable for multiple cigarette inspections. The invention can realize the automation of sample preparation scheme generation, cigarette coding and cigarette composition. Background technique [0003] At present, in the process of smoking evaluation of cigarettes, there are mainly three-point inspection, comparative inspection and sorting inspection. [0004] 1. Three-point test [0005] As a differential test method, the three-point test is widely used in the industry in the cigarette product development process, product formulation adjustment and maintenance, and daily product quality stability judgment. YC / T138-1998 "Tobacco and Tobacco Products Sensory Evaluation Methods" standard specifies the general requirements and testing methods for tobacco and tobacco products sensory evaluation methods,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65B19/02B65B35/02B65B63/00

Inventor 李栋赵航范黎文锦孟秦冬李锦马明陈连芳孟庆华

Owner ZHENGZHOU TOBACCO RES INST OF CNTC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com