Combined rudder surface of a tailless aircraft

A tailless aircraft, combined rudder technology, applied in aircraft parts, aircraft control, transportation and packaging, etc., can solve problems such as unfavorable pitching moment, large coupling rolling moment, etc., to increase longitudinal static stability and improve flight safety. , the effect of simplifying the control law of the rudder surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings.

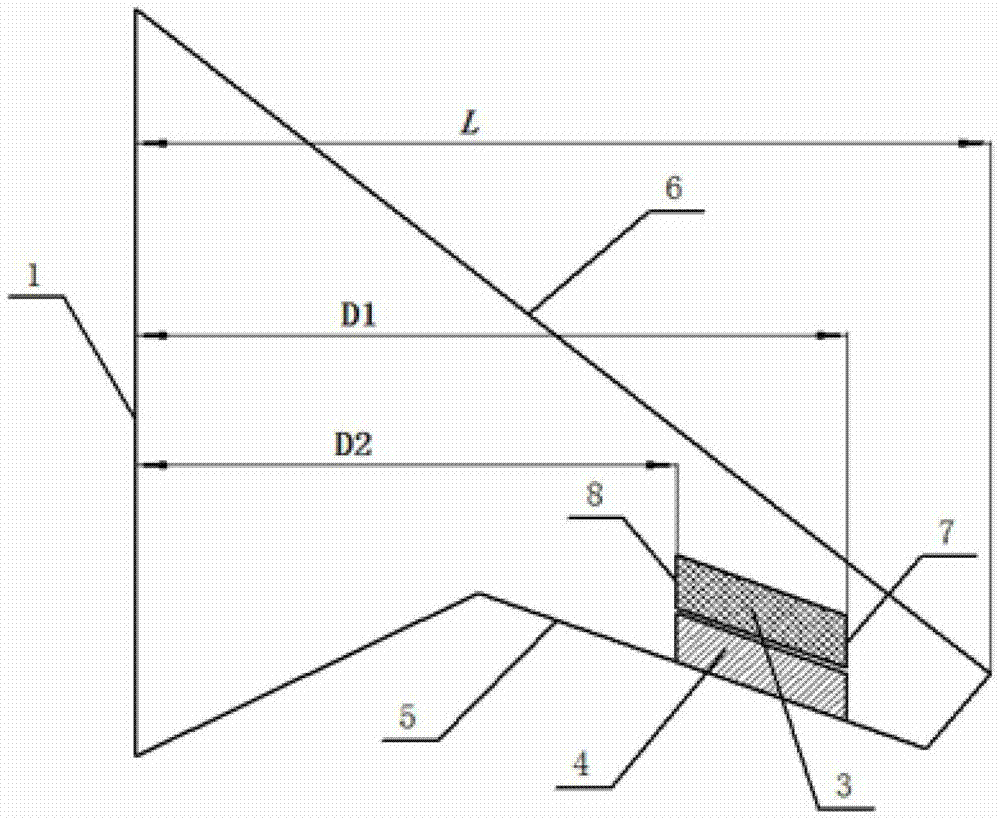

[0047] The top view of the tailless body fusion aircraft is as follows figure 1 shown. The wings on both sides of the fuselage are respectively arranged with a group of combined control surfaces 2, and the combined control surfaces 2 on both sides of the wings are symmetrical to each other. Because the geometric symmetry of the whole machine and the rudder surface are also arranged symmetrically, the present invention is only described with one side, as figure 2 shown.

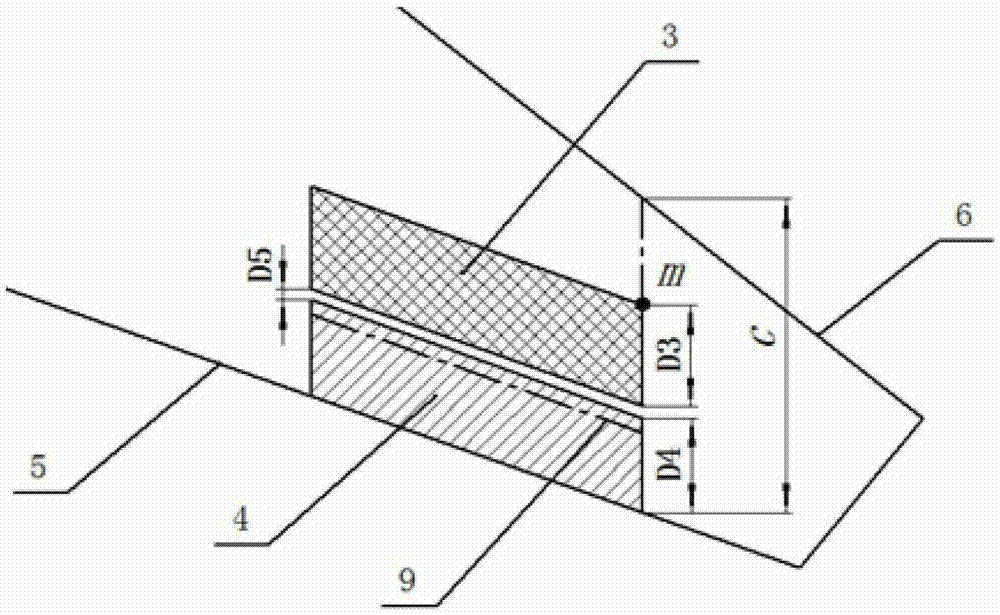

[0048] The combined rudder surface 2 includes an embedded rudder surface 3 and an elevon 4 . The external dimensions of the embedded rudder surface 3 and the elevon 4 are the same, and both are parallelograms. The two straight sides of the parallelogram profile that constitute the embedded control surface 3 and the elevon 4 are all parallel to the fuselage central axis 1; the two sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com