Device for installing thermocouple on reactor in propenoic acid production

A technology of thermocouples and reactors, which is applied in the direction of using electric devices, measuring devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problems of difficulty in vertical installation of multi-point thermometers, and achieve reliable temperature detection. The effect of high propylene conversion rate and reduced operation risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

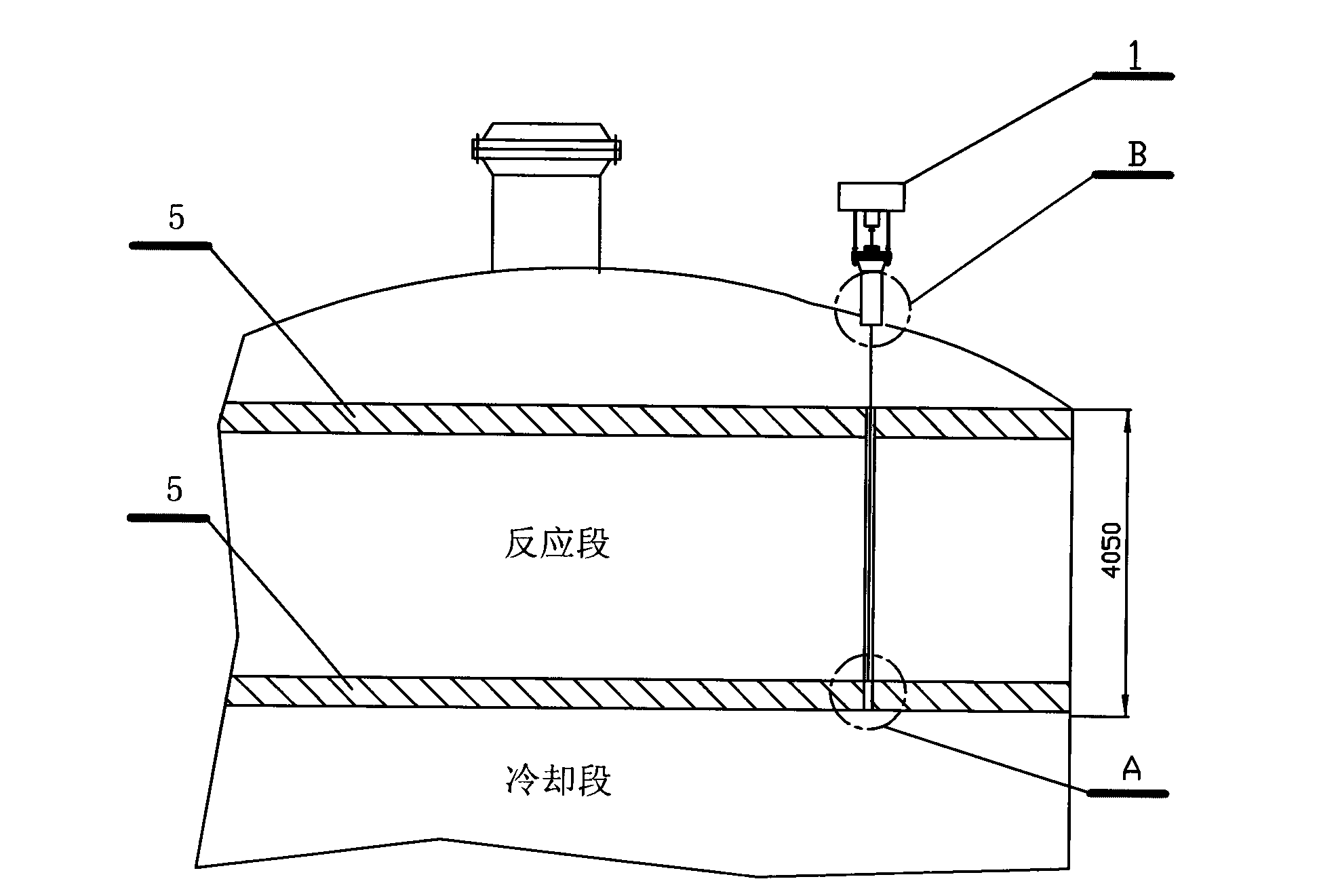

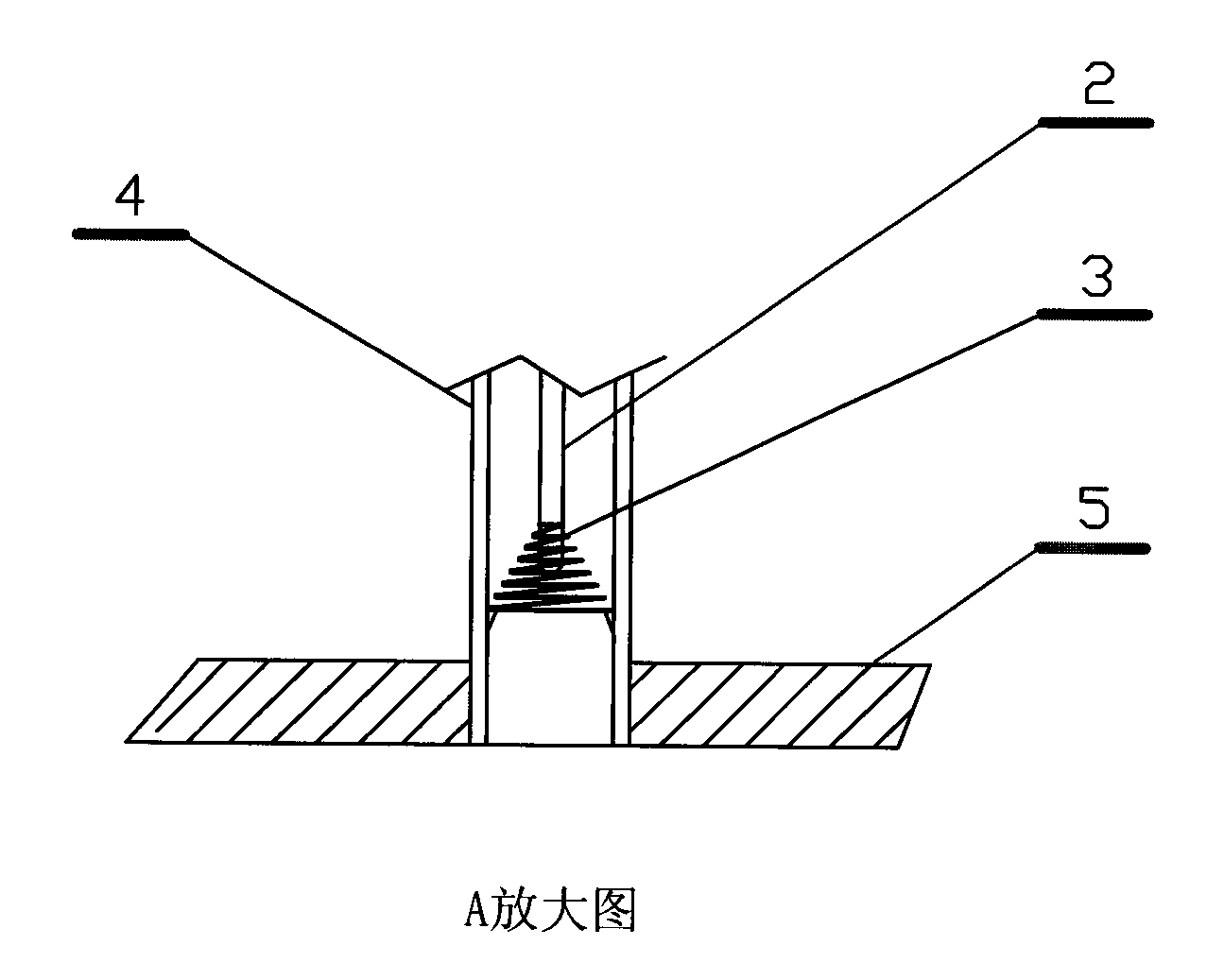

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

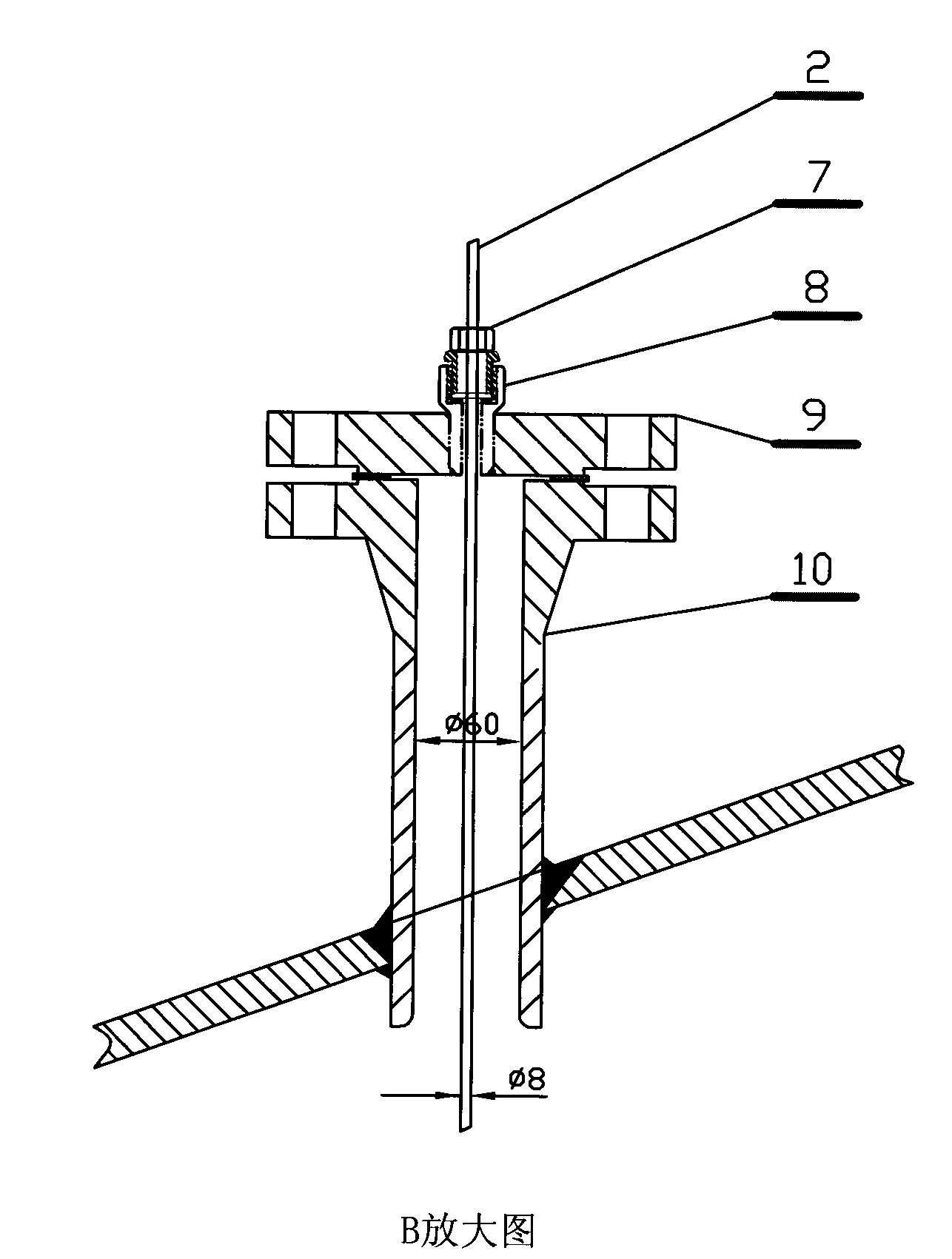

[0023] Problems with the temperature measuring device of the acrylic acid oxidation reactor: one is the vertical installation of the multi-point thermometer, and each temperature measuring point is effectively fixed at the detection position through the fins, which prevents the bridge between the thermometer and the reactor tube; the other is the movable card The sleeve solves the sealing between the thermometer and the casing, and can flexibly adjust the fixed position, making the on-site installation flexible and convenient; third, the existence of the fins 6 adjusts the resistance drop after the catalyst is installed, and reduces the difficulty of catalyst installation.

[0024] A short flange pipe 10 is arranged on the head cover of the reactor, and a flange 9 is provided on the short flange pipe 10. A straight connector 8 is arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com