Novel microchip laser supporting optical fiber output

A microchip laser and optical fiber technology, applied in the field of laser technology and nonlinear optics, can solve the problems affecting operation and application, difficult beam, beam divergence, etc., to achieve easier collection and monitoring, reduce laser volume, and increase structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

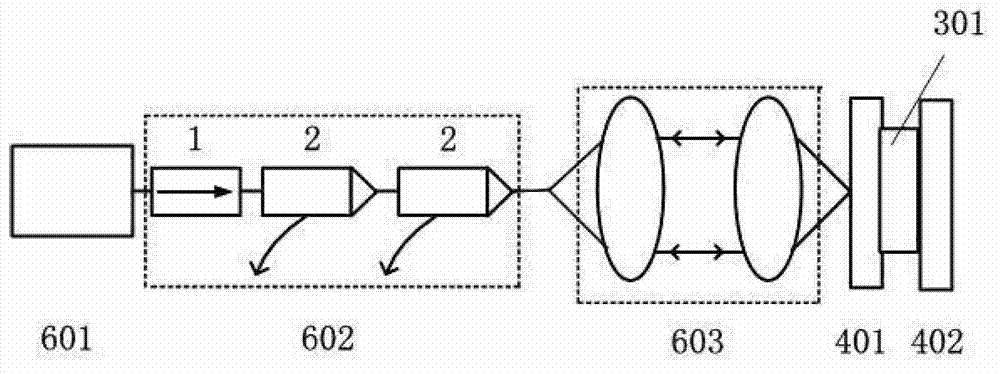

[0028] A new microchip laser structure capable of fiber output such as figure 1 shown. 601 in the figure is the pump source, which can be selected as a semiconductor laser diode with a center wavelength of 976nm and fiber-coupled output; 602 is an optical fiber output system, including an isolator 1 and two wavelength division multiplexing fiber couplers 2. The isolator is to prevent The feedback light will affect and damage the pump source, and the wavelength division multiplexing fiber coupler is used for the output of the laser; 603 is an optical collimation system, including two lenses, which collimate and focus the beam; 401 and 402 are coated optical components , the front optical element 401 is coated with an anti-reflection optical film for pump light and a total reflection optical film for laser light, and the rear optical element 402 is coated with an optical film for total reflection of laser light; 301 is Yb:GdCOB crystal; optical elements 401, 402 A parallel plan...

Embodiment 2

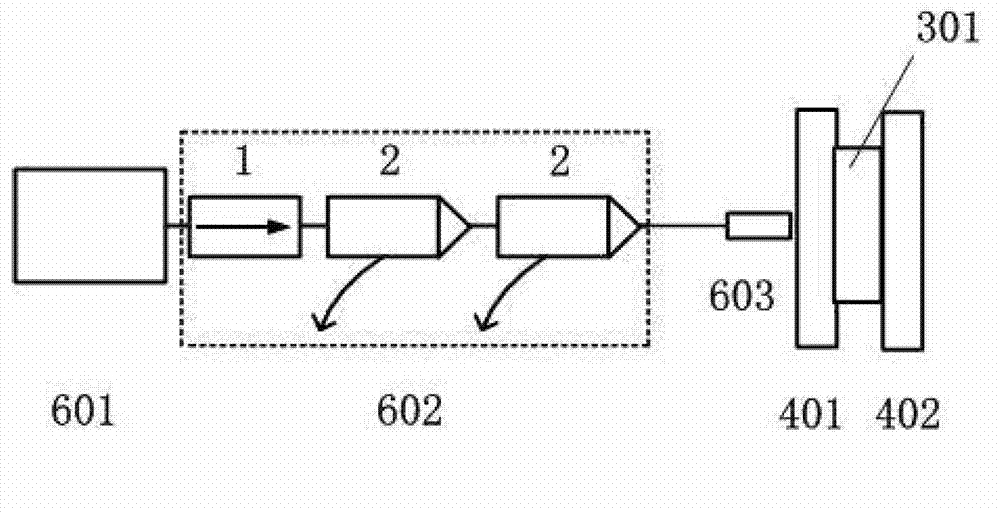

[0032] A new microchip laser structure capable of fiber output such as figure 2 shown. 601 in the figure is the pump source, which can be selected as a semiconductor laser diode with a center wavelength of 976nm and fiber-coupled output; 602 is an optical fiber output system, including an isolator 1 and two wavelength division multiplexing fiber couplers 2. The isolator is to prevent The feedback light will affect and damage the pump source, and the wavelength division multiplexing fiber coupler is used for the output of the laser; 603 is the optical collimation system, which uses a lens to realize the collimation and focusing of the beam; 401 and 402 are the coated optical components, the front The optical element 401 is coated with an anti-reflection optical film for pump light and a total reflection optical film for laser light, and the rear optical element 402 is coated with a total reflection optical film for laser light; 301 is a Yb:GdCOB crystal; optical elements 401 a...

Embodiment 3

[0035] A new microchip laser structure capable of fiber output such as image 3shown. 601 in the figure is the pump source, which can be selected as a semiconductor laser diode with a center wavelength of 976nm and fiber-coupled output; 602 is an optical fiber output system, including an isolator 1 and two wavelength division multiplexing fiber couplers 2. The isolator is to prevent The feedback light will affect and damage the pump source, and the wavelength division multiplexing fiber coupler is used for the output of the laser; 603 is the optical collimation system, and the Grin prism is used to cling to the pump incident end face; 401 and 402 are the coated optical components, the front The optical element 401 is coated with an anti-reflection optical film for pump light and a total reflection optical film for laser light, and the rear optical element 402 is coated with a total reflection optical film for laser light; 301 is a Yb:GdCOB crystal; optical elements 401 and 402...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com