Manual lithography machine aligns the workbench z-direction coarse micro-motion mechanism

A workbench and lithography machine technology, which is applied to microlithography exposure equipment, optics, mechanical equipment, etc., can solve the problems of inability to achieve micro separation changes, affecting the quality of chip graphics, and unadjustable fixed values, achieving a simple structure. , The effect of small leveling force and adjustable leveling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

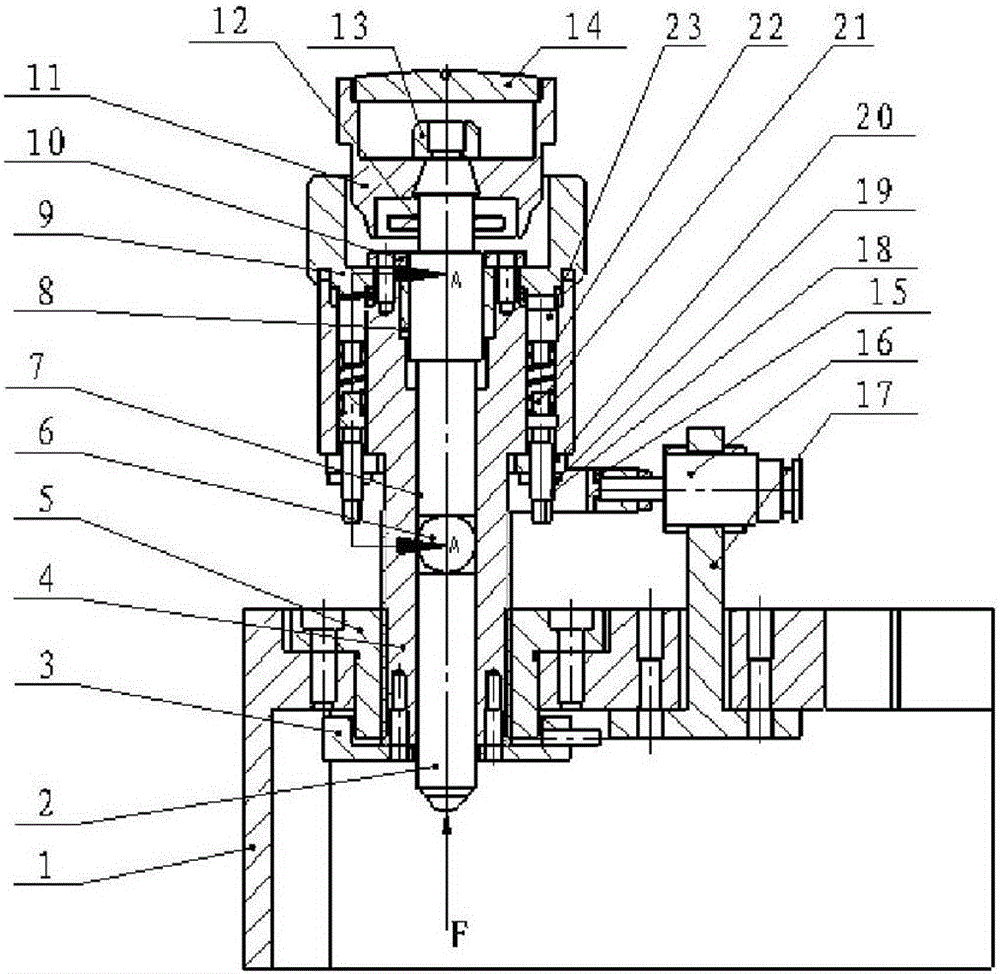

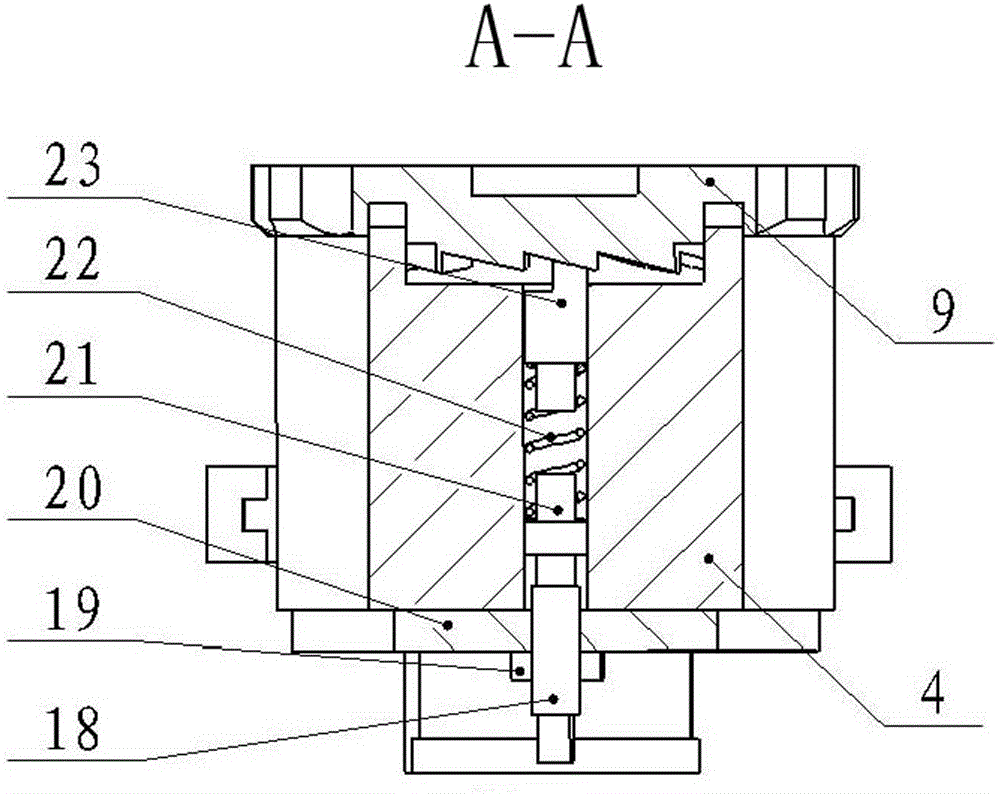

[0018] Such as figure 1 , figure 2 Shown, the present invention is a kind of brand-new design. The manual lithography machine of the present invention aligns the Z-direction coarse and fine movement mechanism of the workbench by a differential thread mechanism, a ratchet friction force adjustment mechanism, a friction ratchet mechanism, a coarse movement locking mechanism, a fine movement limit device and a coarse movement limit device And a structural frame 1 is formed.

[0019] The differential screw mechanism is composed of: the structural frame 1 is fixedly connected with a large screw nut 5, and the large screw nut 5 is threaded to connect with the large screw 4. The appearance of the large screw 4 is T-shaped with a large cylinder at the top and a small cylinder at the bottom. There is a central assembly hole on the 4 axis of the large screw, and the upper part of the assembly hole is stepped. A small screw nut 8 is fixed at the stepped part of the assembly hole. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com