Method for measuring leakage of propylene

An acrylic and test source technology, applied in the field of automatic installation of oil rails, can solve the problems of high energy consumption and low detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The utility model will be further described below in conjunction with the accompanying drawings and embodiments.

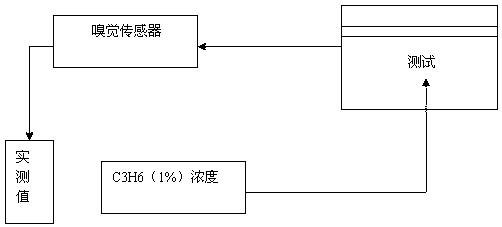

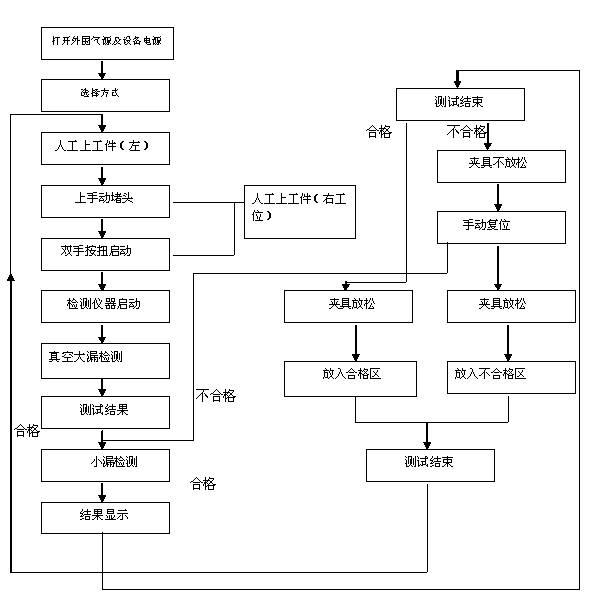

[0007] 1. The test principle is as follows: figure 1 Shown: Test cycle process: Manually put the workpiece under test into the sealed cover, connect the ATEQT520 measuring instrument to the acrylic gas pipe, start the button, and the cycle starts—waiting time—inflate—stabilize—test—exhaust Air - end of cycle

[0008] - Use C3H6 (1% concentration) for gas method test;

[0009] — Using a special valve group, it can guarantee a service life of more than 5 million times without leakage;

[0010] — Using a special sensitive olfactory sensor can ensure the accuracy and stability of the test, and can replace the helium test within a certain range;

[0011] — Time resolution: 1 / 10 second (inflate, stabilize, test, etc.);

[0012] — Display and monitor test pressure;

[0013] — There are input / output interfaces that can be connected with PLC signals for automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com