On-line Calculation Method of Main Steam Flow in Power Plant Based on Performance Test Data

A technology of main steam flow and test data, which is applied in the field of online calculation of main steam flow in power plants, can solve the problems of large actual deviation, difficult to measure, and does not consider the influence of low-pressure cylinder exhaust steam pressure, and achieves small deviation and easy operation. , the effect of the simple correction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

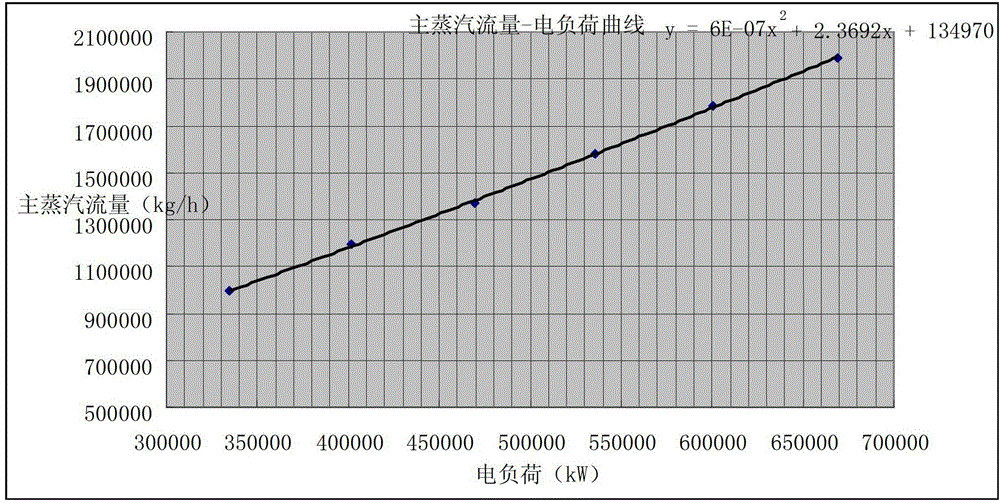

[0029] Example: Table 1 shows the performance test data of a 670MW unit steam turbine in a certain power plant. According to the data in the table, the test main steam flow-electric load curve can be drawn as figure 1 shown, and find the main parameters of the test conditions in it. like figure 1 As shown in the test main steam flow-electric load curve, according to the curve fitting formula, the corresponding test main steam flow can be calculated from the actual load.

[0030] Table 1

[0031]

[0032] Taking another 500MW working condition in the performance test as an example to calculate the actual main steam flow for comparison, the working condition parameters are shown in Table 2.

[0033] Table 2

[0034]

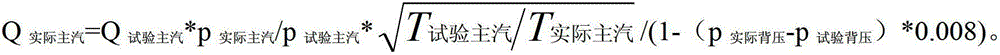

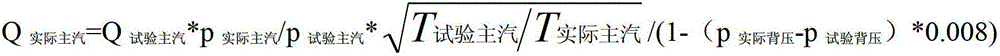

[0035] The calculation method of the present invention: first obtain the corresponding test main steam flow rate of 151752.5kg / h according to the test main steam flow-electric load curve, and then select the nearest test 80% electric load working conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com