Electromagnetic damping vibration isolator with coplanar air floatation orthogonal decoupling function and angular decoupling function by aid of sliding joint bearing

A technology of sliding joints and electromagnetic damping, which is applied in the direction of bearings, shafts and bearings, springs/shock absorbers, etc., can solve the problems of poor positioning accuracy, large pendulum length, and string-film resonance of air spring vibration isolators, etc., to achieve Solve the effect of low positioning accuracy and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

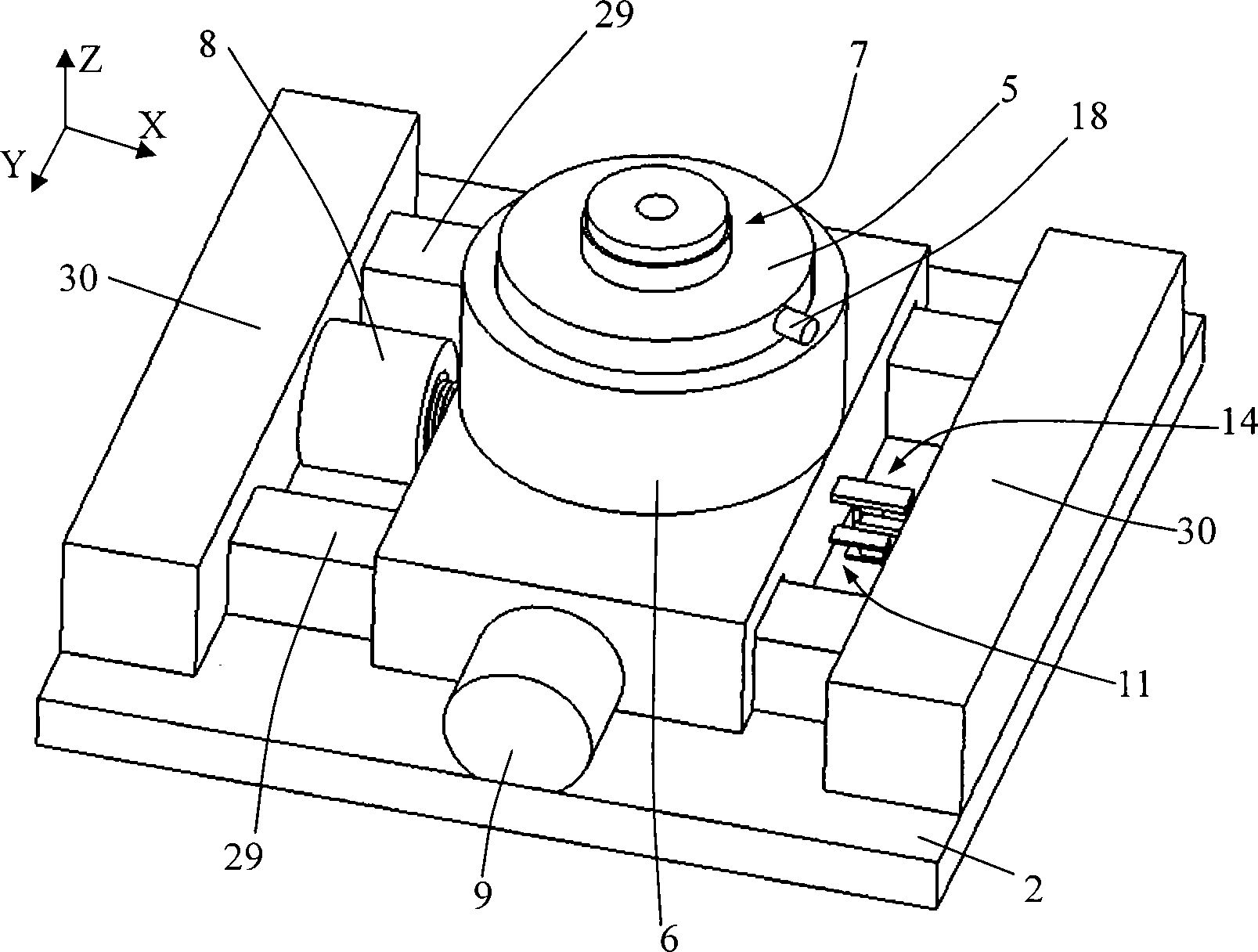

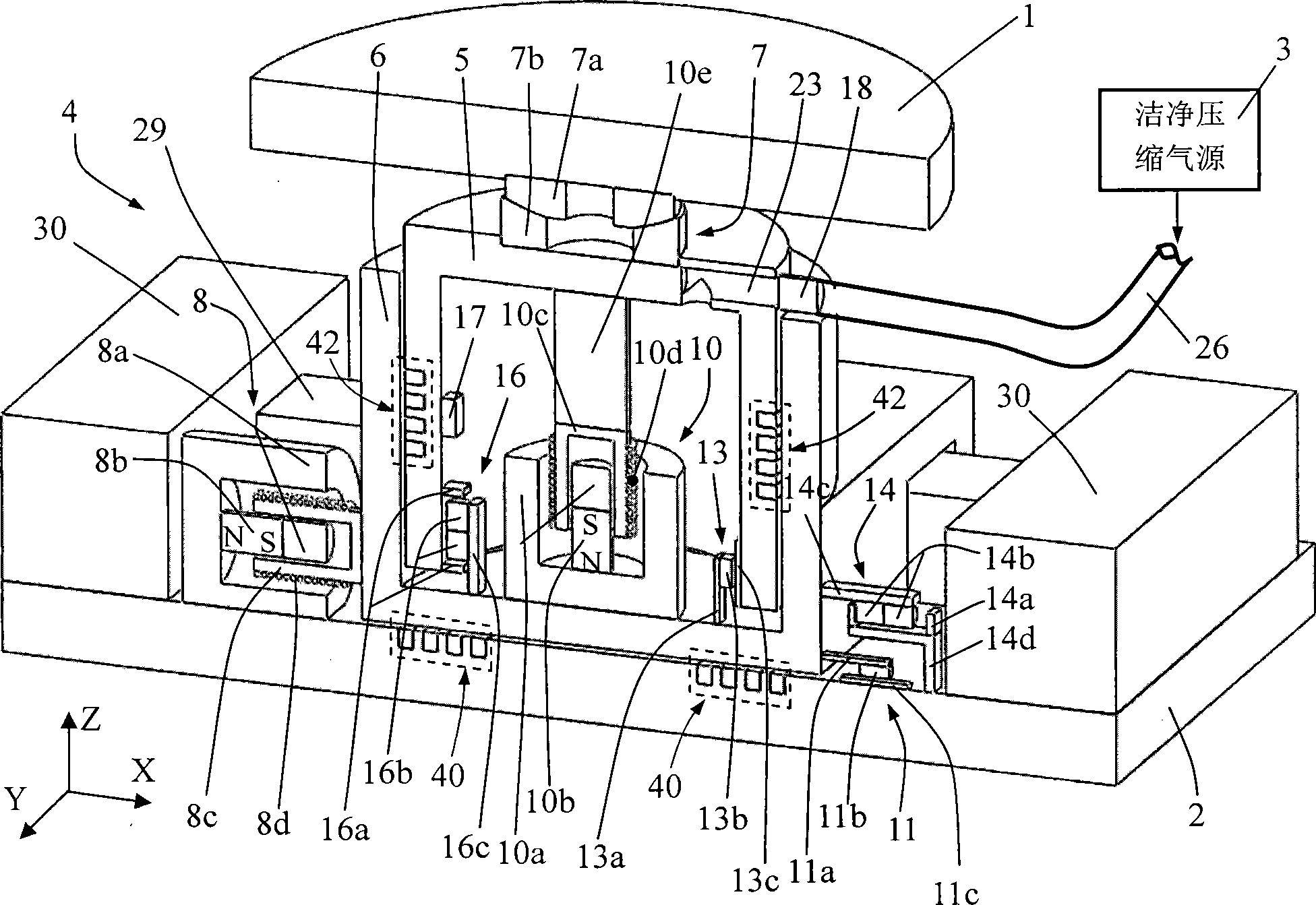

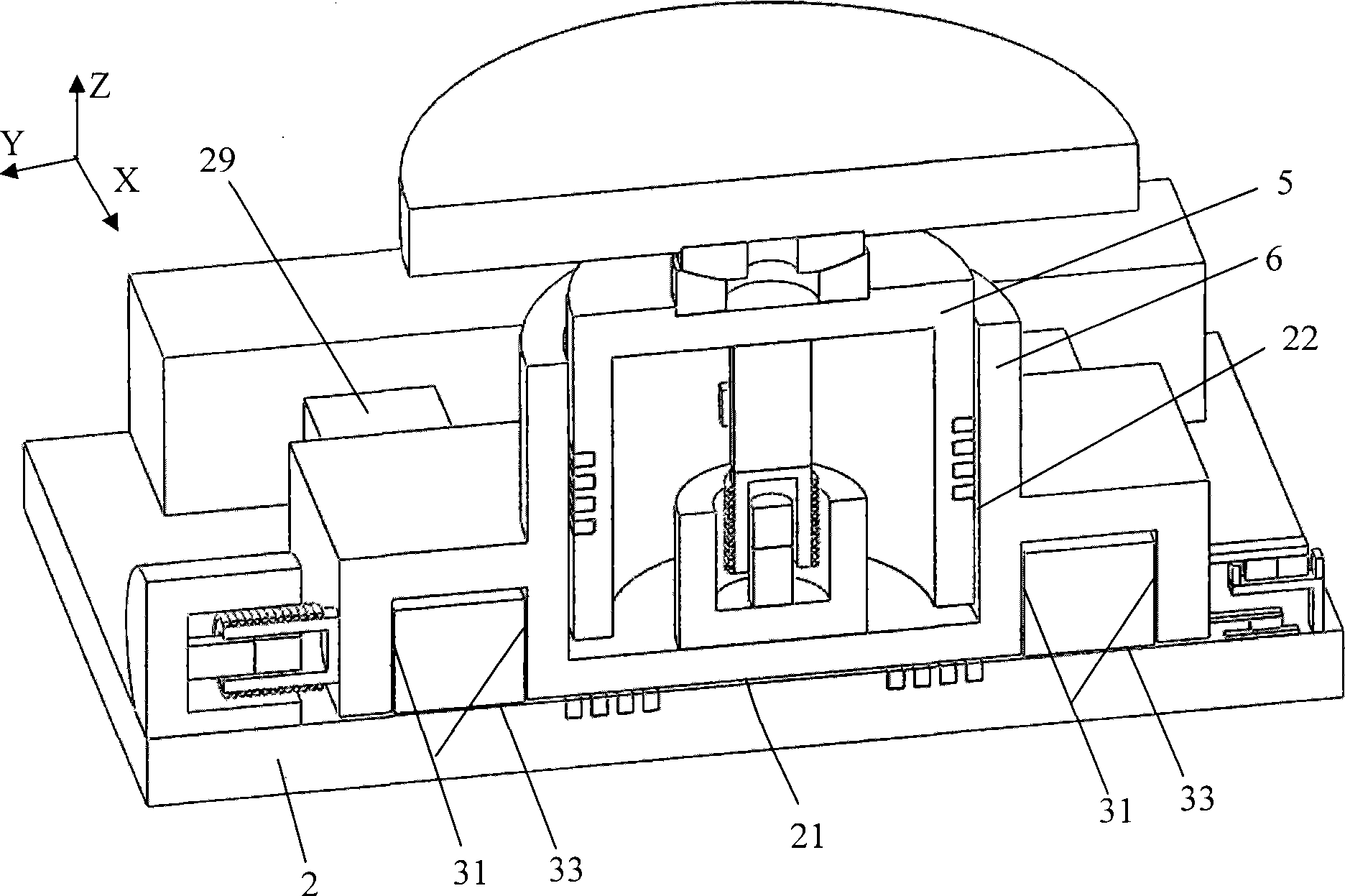

[0041] Specific embodiments of the present invention are given below in conjunction with the accompanying drawings.

[0042] An electromagnetic damping vibration isolator with coplanar air bearing orthogonal decoupling and sliding joint bearing angle decoupling, consisting of an upper mounting plate 1, a lower mounting plate 2, a clean compressed air source 3, an air pipe 26 and a vibration isolator body 4 The vibration isolator main body 4 is installed between the upper mounting plate 1 and the lower mounting plate 2, and the clean compressed air source 3 is connected to the vibration isolator main body 4 through the air pipe 26. In the structure of the vibration isolator main body 4, the sleeve 6 The lower surface and the lower mounting plate 2 are lubricated and supported by the axial bearing plane air bearing surface 21, the piston barrel 5 is installed in the sleeve 6 undercut, and lubricated and supported with the sleeve 6 by the radial bearing cylindrical air bearing sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com