Hydraulic hybrid power concrete mixing carrier control system

A mixer truck and hybrid technology, applied in control devices, clay preparation devices, cement mixing devices, etc., can solve the problems of large energy consumption, pressure shock, and self-loading of the whole system, and achieve easy realization and balanced pressure shock. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

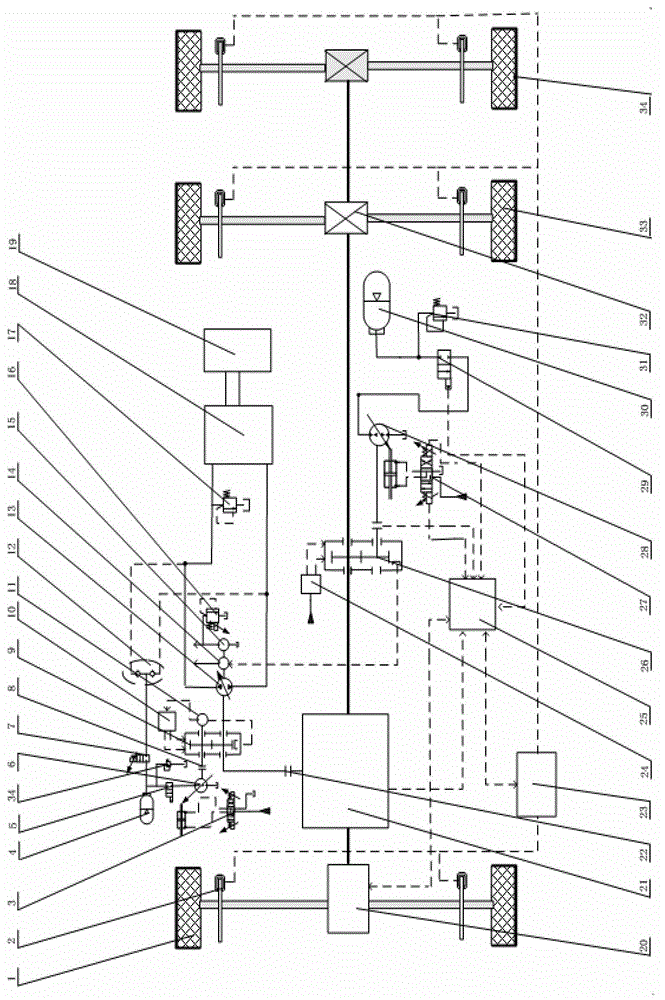

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] Such as figure 1 As shown, a control system of a hydraulic hybrid concrete mixer truck includes an on-board mixing system and an off-board driving system. The on-board mixing system includes a closed main pump 13, a servo valve 18, a mixing mechanism 19, an engine 20, and a main transmission The box 21 and the clutch II 22, the engine 20 are connected through the main gearbox 21 and the clutch II 22, the output end of the clutch II 22 is connected with the input shaft of the closed main pump 13, and the output port of the closed main pump 13 is connected with the inlet of the servo valve 18, The output port of the closed main pump 13 is also connected with the safety valve I17, the safety valve I17 limits the safety pressure of the system during the top-loading stirring operation, and the servo valve 18 is connected with the input end of the stirring mechanism 19; T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap