Shaker capable of preventing reagent bottles from being broken and used for mixing materials in the reagent bottles

A reagent bottle, anti-shattering technology, applied in mixers, shaking/oscillating/vibrating mixers, dissolving and other directions, can solve the problems of time-consuming and laborious, and achieve the effects of convenient operation, labor saving and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

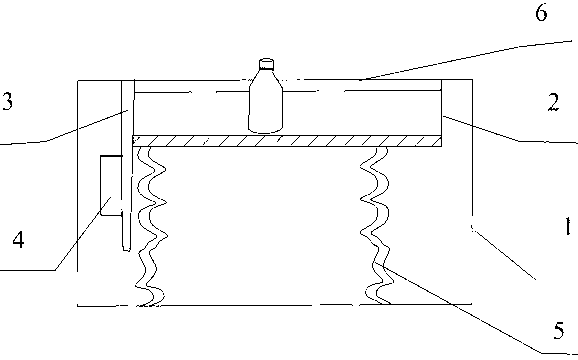

[0023] like figure 1 , 2 , an oscillator for mixing anti-shattering reagent bottles, including a housing 1, a bearing plate 2 is arranged above the housing, one side of the bearing plate is fixedly connected to a connecting plate 3, and a driving connecting plate is provided on the connecting plate Motor 4 for up and down motion.

[0024] The bearing plate is connected to the bottom of the housing through a spring 5 .

[0025] The number of said springs 5 is four.

[0026] The carrying plate has a double-layer structure, the upper layer is provided with a reagent bottle clamping structure, and the lower layer is a supporting plate; the reagent bottle clamping structure is composed of a spring network 6 .

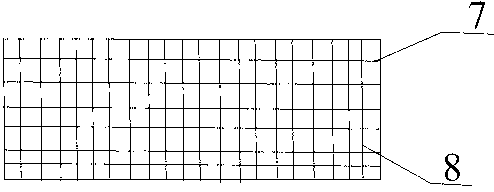

[0027] The spring network is composed of horizontal springs 7 and longitudinal springs 8 that intersect vertically in pairs.

Embodiment 2

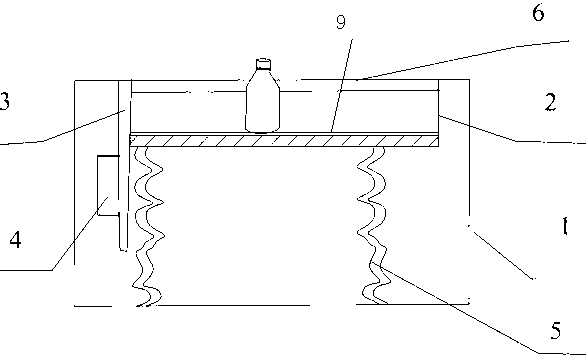

[0029] like figure 1 , 2 , 3, and 4, the difference between this embodiment and embodiment 1 is: based on the implementation structure of embodiment 1, we can see that when moving, the carrier plate 2 and the reagent bottle move up and down together. Due to the principle of inertia, we It can be known that the reagent bottle will generate inertia in the process of rising, so it will cause the reagent bottle and the carrier plate 2 to move asynchronously. For this reason, generally people set the diameter of the spring network 6 on the upper layer to be smaller than the diameter of the mouth of the reagent bottle. . This method is not easy to realize, and the reason why it is difficult to realize is that the structure of the general reagent bottle is from the direction of the bottle mouth to the direction of the bottom of the bottle, and its diameter will always become larger. Therefore, the above-mentioned design does not meet the needs of modern reagent bottles. For this rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com