Oil furnace flue gas purification compound tower integrating dust removal, smoke abatement and desulphurization

A technology of flue gas purification and composite tower, which is applied in the direction of combined devices, chemical instruments and methods, and separation of dispersed particles, and can solve the problems of uneven gas field distribution, large circulation volume, and large power consumption in the tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

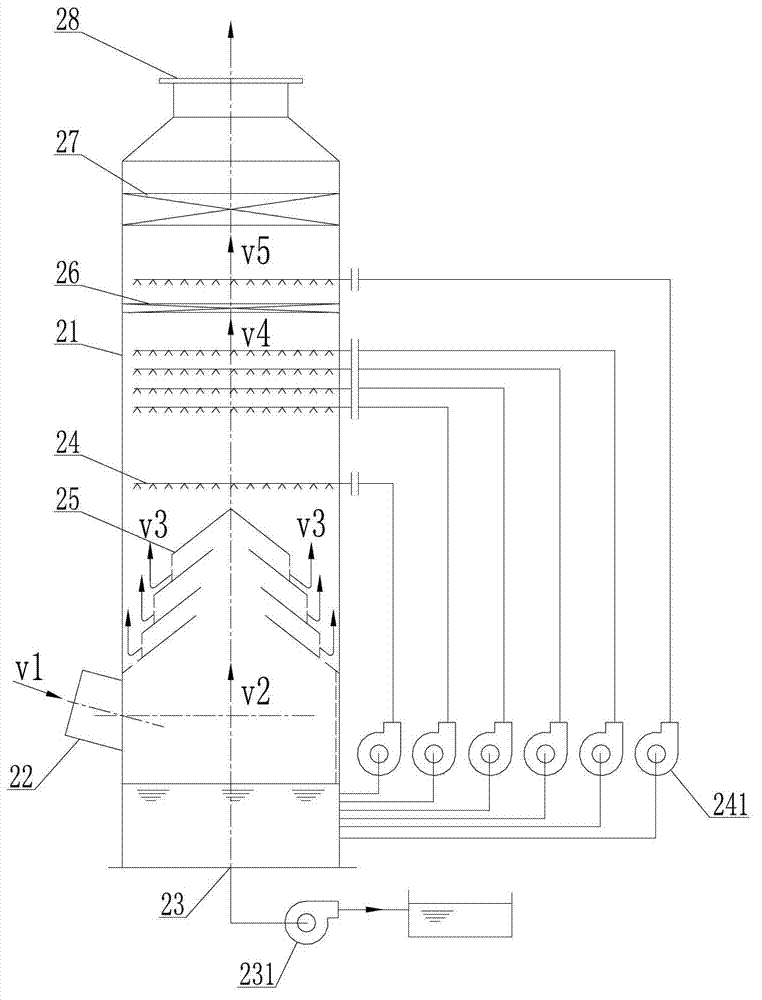

[0017] The present invention proposes a composite tower structure for oil furnace flue gas purification that integrates dust removal, smoke elimination, and desulfurization. figure 2 As shown, it includes: a housing 21, a flue gas inlet 22 arranged at the lower part of the housing, a slurry discharge port 23 provided at the bottom of the housing, a slurry discharge pump 231 connected to the slurry discharge port, and a vertical arrangement arranged at the upper part of the flue gas inlet. The multi-stage spray pipe 24, the circulation pump 241 in the circulation pipe communicated with the spray pipes of all levels respectively, the umbrella device 25 arranged under the spray pipe of the lowest stage, and the umbrella device 25 arranged on the uppermost stage and the second stage A layer of orifice plate 26 between the primary spray pipes, a mist eliminator 27 arranged above the spray pipes, and a smoke outlet 28 arranged on the top of the casing.

[0018] The present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com