Tobacco leaf threshing and redrying process

A technology of threshing and redrying, process, applied in the treatment of tobacco, tobacco, application, etc., can solve the problems of increased crushing rate and energy consumption, and achieve the effects of reducing crushing rate, improving filling capacity, and effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

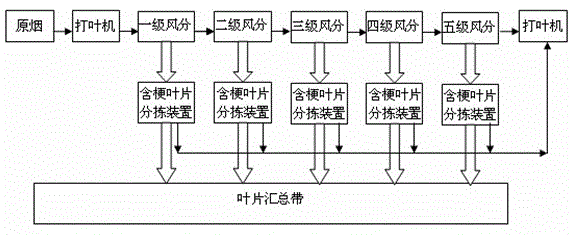

[0036] Example 1 (eg figure 1 )

[0037] A threshing and redrying process, comprising a tobacco leaf wetting step and a leaf threshing step for wetting the tobacco leaves, characterized in that the threshed tobacco leaves undergo the following steps:

[0038] A. On the air separation unit, carry out primary winnowing to the tobacco leaves after threshing according to the air separator efficiency 62%, and obtain the winnowing product and the winnowing residue with a stalk-containing rate of 2.3%, and the winnowing product is sent into the air-separating product containing In the stalk leaf sorting device, the product and residue are further separated, the product is sent out through the leaf collection belt, and the residue is returned to leaf threshing;

[0039] B, on the secondary air separation unit, under the condition that the efficiency of the air separator is 62%, the wind selection residue of step A is carried out by wind selection, and the wind separation product and...

Embodiment 2

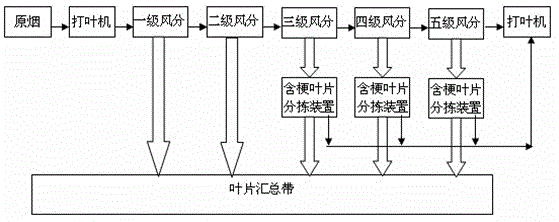

[0045] Example 2 (eg figure 2 )

[0046] A threshing and redrying process, comprising a tobacco leaf wetting step and a leaf threshing step for wetting the tobacco leaves, characterized in that the threshed tobacco leaves undergo the following steps:

[0047] A. On the air separation unit, under the condition that the efficiency of the air separator is 50%, the tobacco leaves after threshing are carried out to a first-level winnowing, and the winnowing product and the winnowing residue with a stalk rate of 1.8% are obtained. The selected product is directly sent out through the blade collection belt;

[0048] B, on the secondary air separation unit, under the condition that the air separator efficiency is 55%, the air selection residue of step A is carried out by air selection, and the air selection product and air selection residue with a stalk rate of 2% are selected. The air-selected products are directly sent out through the blade collection belt;

[0049] C, on the th...

Embodiment 3

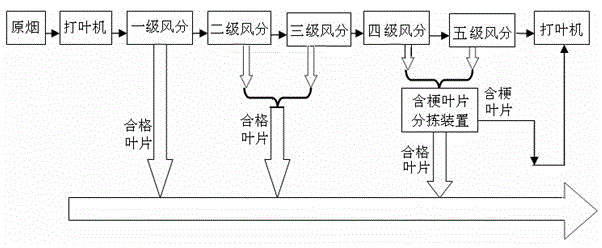

[0054] Example 3 (as image 3 )

[0055] A threshing and redrying process, comprising a tobacco leaf wetting step and a leaf threshing step for wetting the tobacco leaves, characterized in that the threshed tobacco leaves undergo the following steps:

[0056] A. On the air separation unit, under the condition that the efficiency of the air separator is 50%, the tobacco leaves after threshing are carried out to a first-level winnowing, and the winnowing product and the winnowing residue with a stalk rate of 1.8% are obtained. The selected product is directly sent out through the blade collection belt;

[0057] B, on the secondary air separation unit, under the condition that the air separator efficiency is 52%, the air selection residue of step A is carried out by air selection, and the air selection product and air selection residue with a stalk rate of 1.9% are selected. The air-selected products are directly sent out through the blade collection belt;

[0058] C, on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com