Buffering member, shaft coupled structure, and a uniaxial eccentric screw pump

A technology for connecting structural bodies and buffer parts, applied in the field of buffer parts, can solve problems such as failure, impact, and looseness of the driving machine, and achieve the effect of reducing operating funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

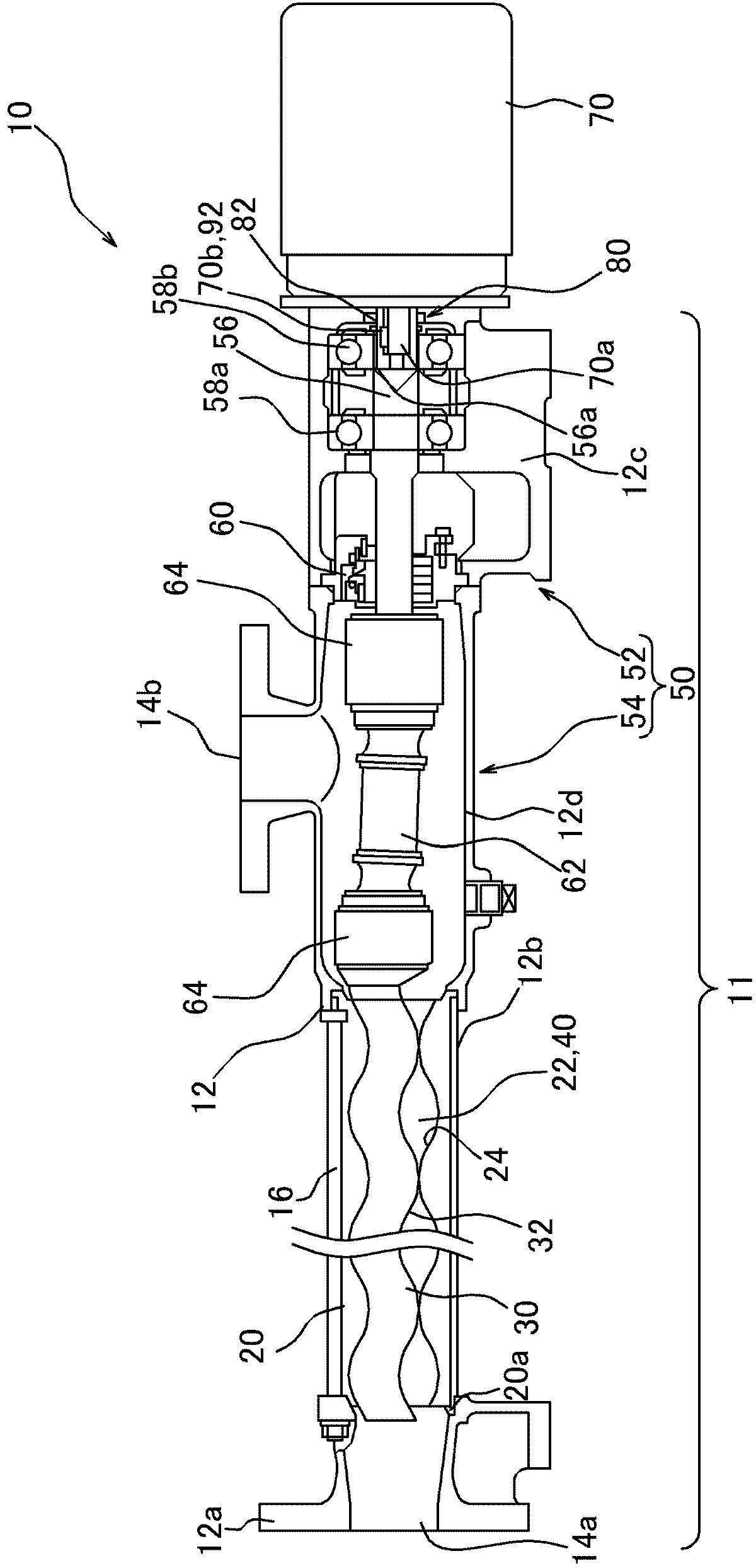

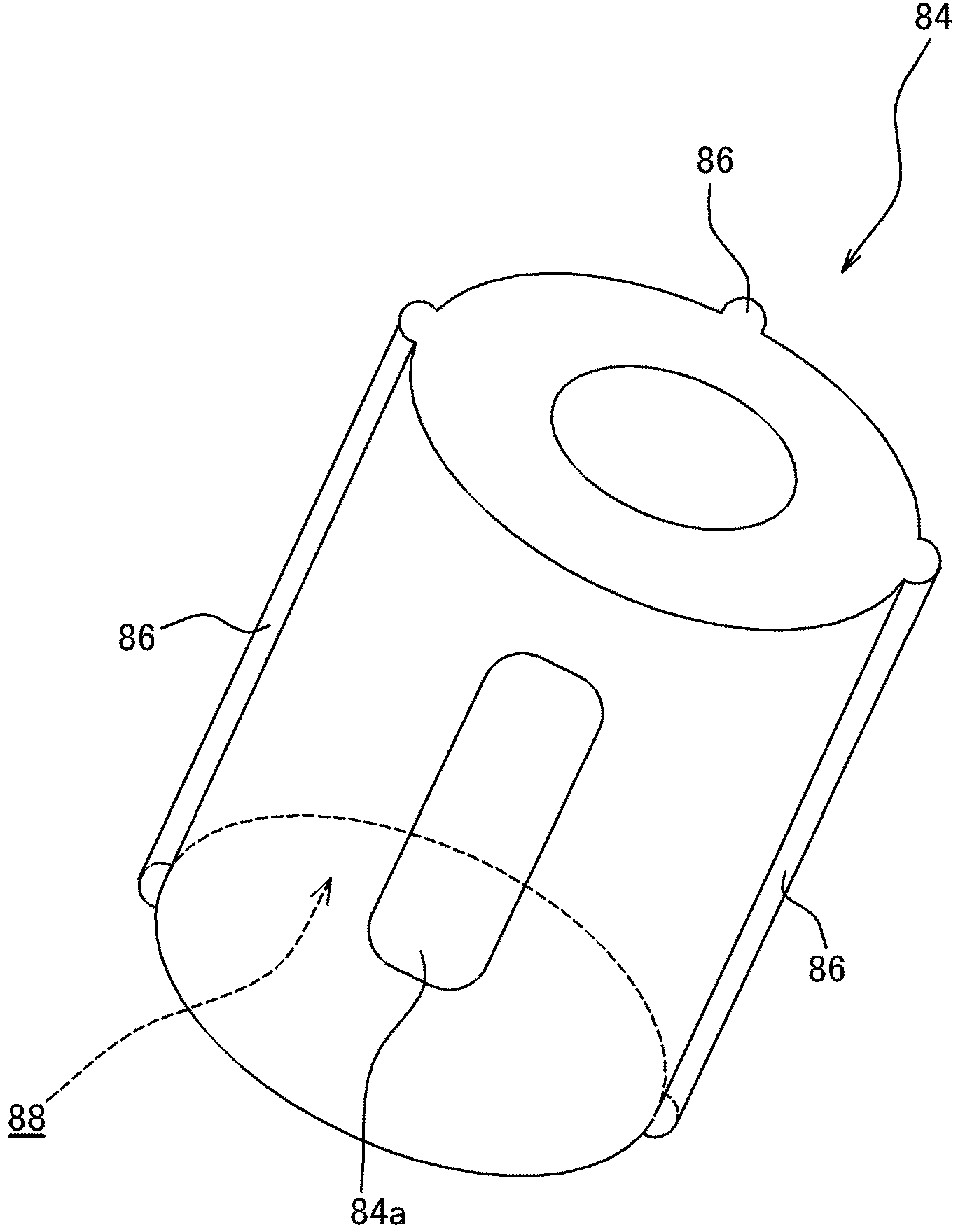

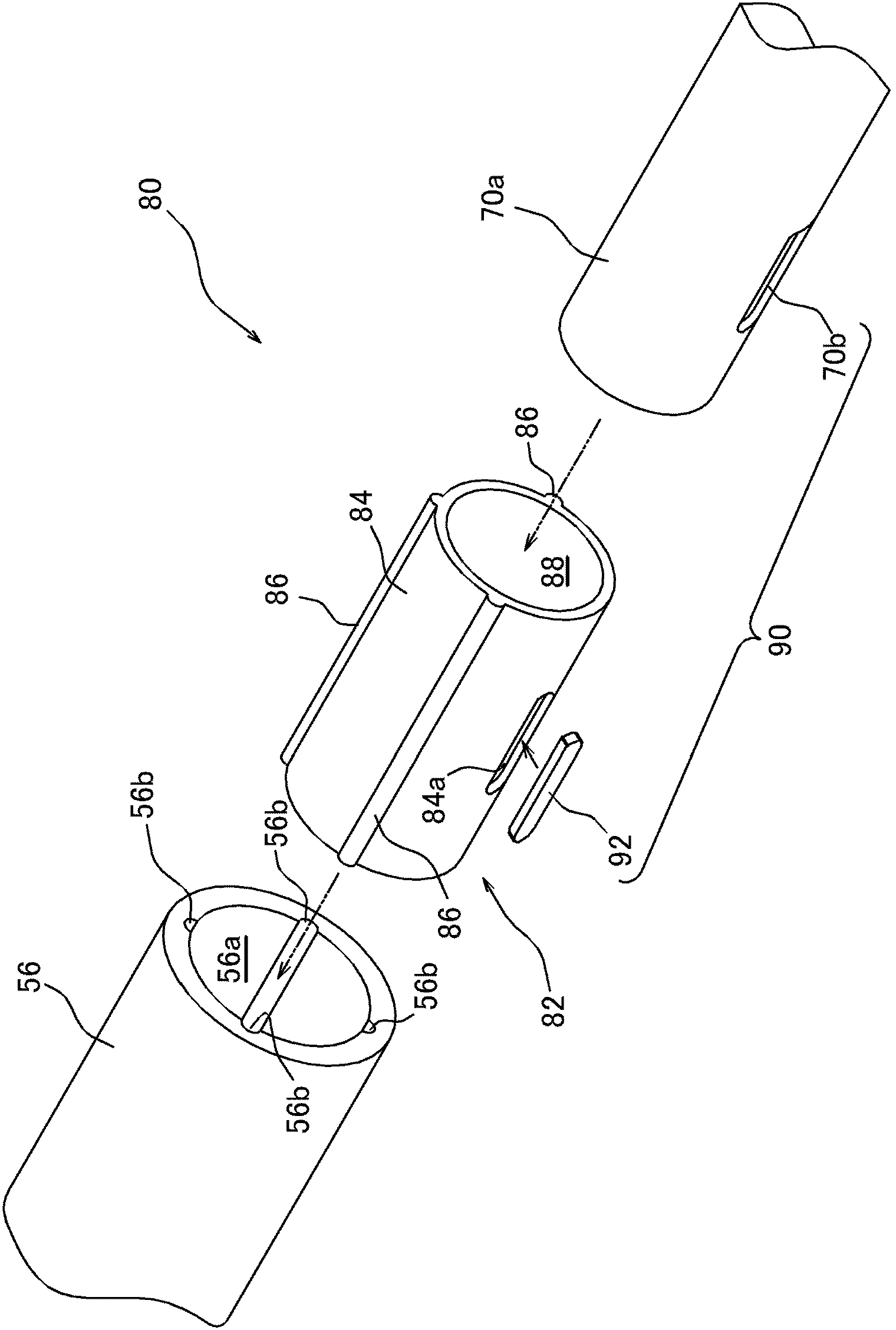

[0054] Next, the uniaxial eccentric screw pump 10 , the shaft connection structure 80 , and the buffer member 82 according to an embodiment of the present invention will be described in detail with reference to the drawings. In addition, the uniaxial eccentric screw pump 10 is characterized by a shaft connection structure 80 and a buffer member 82 . In the following description, before explaining them, the overall structure will be explained.

[0055] "Overall structure of one-axis eccentric screw pump 10"

[0056] The one-axis eccentric screw pump 10 is a so-called rotary positive displacement pump. Such as figure 1 As shown, a stator 20 , a rotor 30 , a power transmission mechanism 50 , and the like are accommodated inside the casing 12 of the one-axis eccentric screw pump 10 , and the power transmission can be transmitted from the driving machine 70 (driver) installed outside the casing 12 . dynamic action. That is, in the uniaxial eccentric screw pump 10 , the part on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com