Superconducting cable line

A technology for superconducting cables and lines, which is applied to the installation of superconducting devices, circuits, cables, etc., and can solve the problems of performance degradation of superconducting cables 10, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

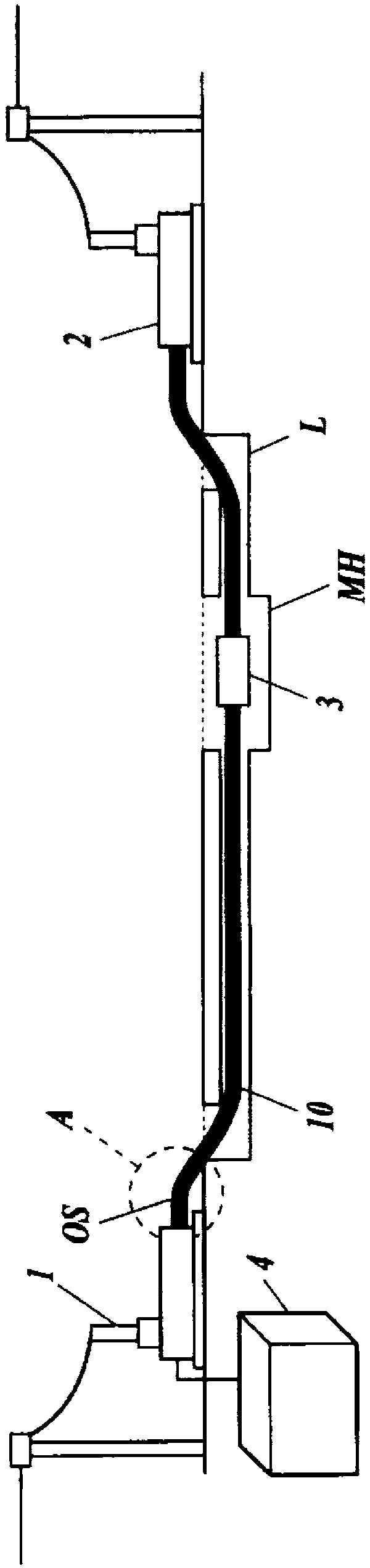

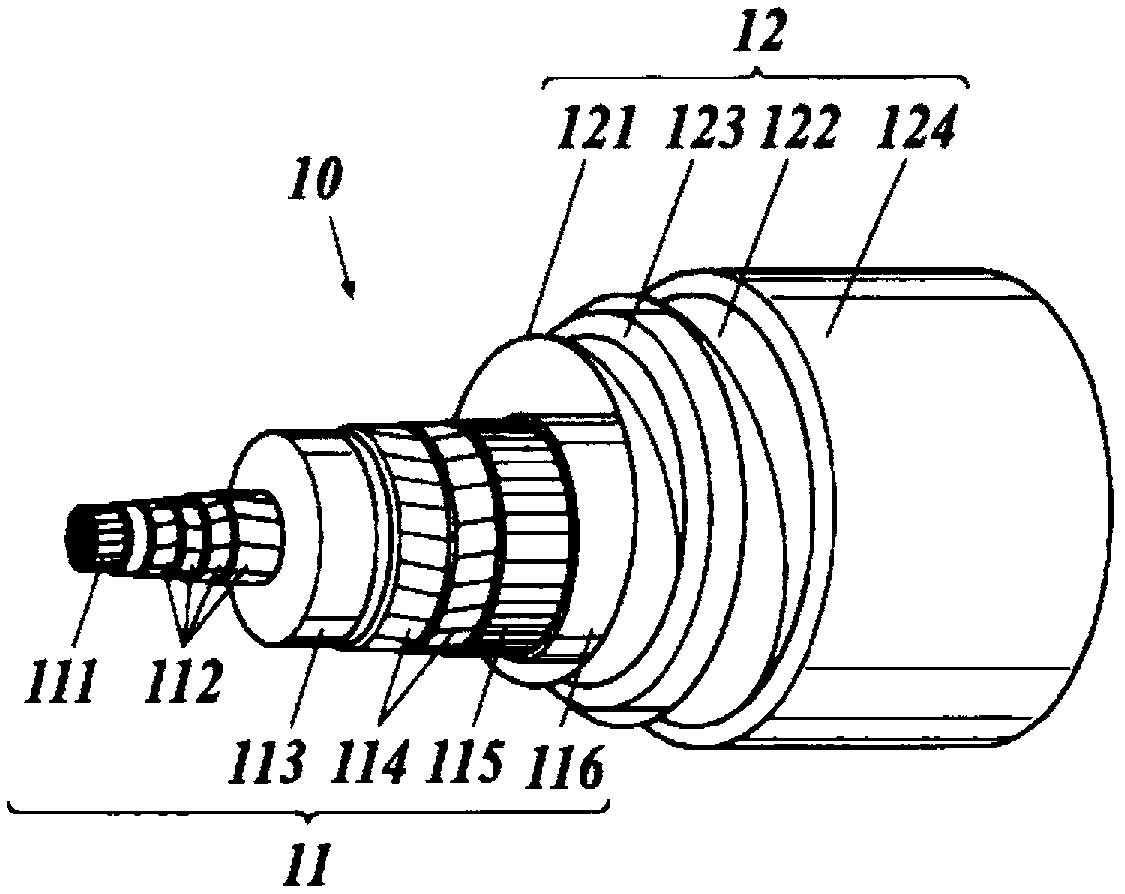

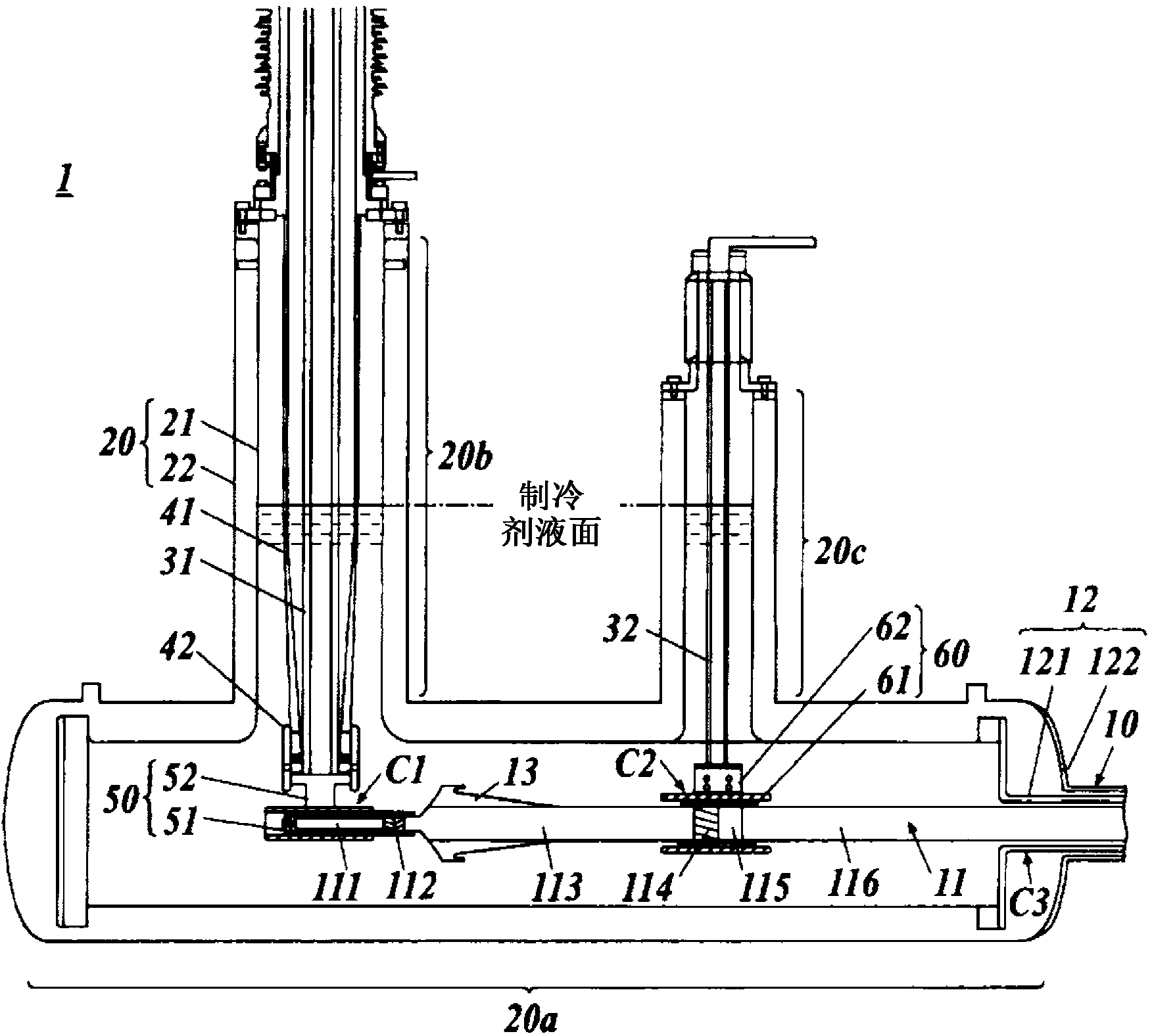

[0124] In the embodiment, one end of a superconducting cable 10 with an outer diameter of 150 mm and a cable length of 50 m is connected to the terminal connection part 1, and the other end is used as a fixed end to construct a simulation from the end of the non-moving region (equivalent to the fixed end) to the terminal. Superconducting cable line for connection 1 (see Figure 10 ). For the case where the compensation part OS was provided with different shapes (including straight laying), the thermal shrinkage when cooling from room temperature to liquid nitrogen temperature was compared with the thermal expansion when heating from liquid nitrogen temperature to room temperature. Specifically, the inside of the movable conductor connection terminal 50 of the terminal connection unit 1 was observed using an observation device using radiation such as X-rays or γ-rays, and the movement amount of the conductor plug 51 in the conductor socket 52 was measured. On the other hand, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com