Automatic rotational lifting monitoring system for fouling and slagging of boiler furnace of coal-fired power plant

A boiler hearth and automatic rotation technology, which is applied in closed-circuit television systems, TV system components, TVs, etc., can solve the problems of inability to detect the furnace, single angle, etc., and achieve the effects of strong economy, slag prevention, and flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

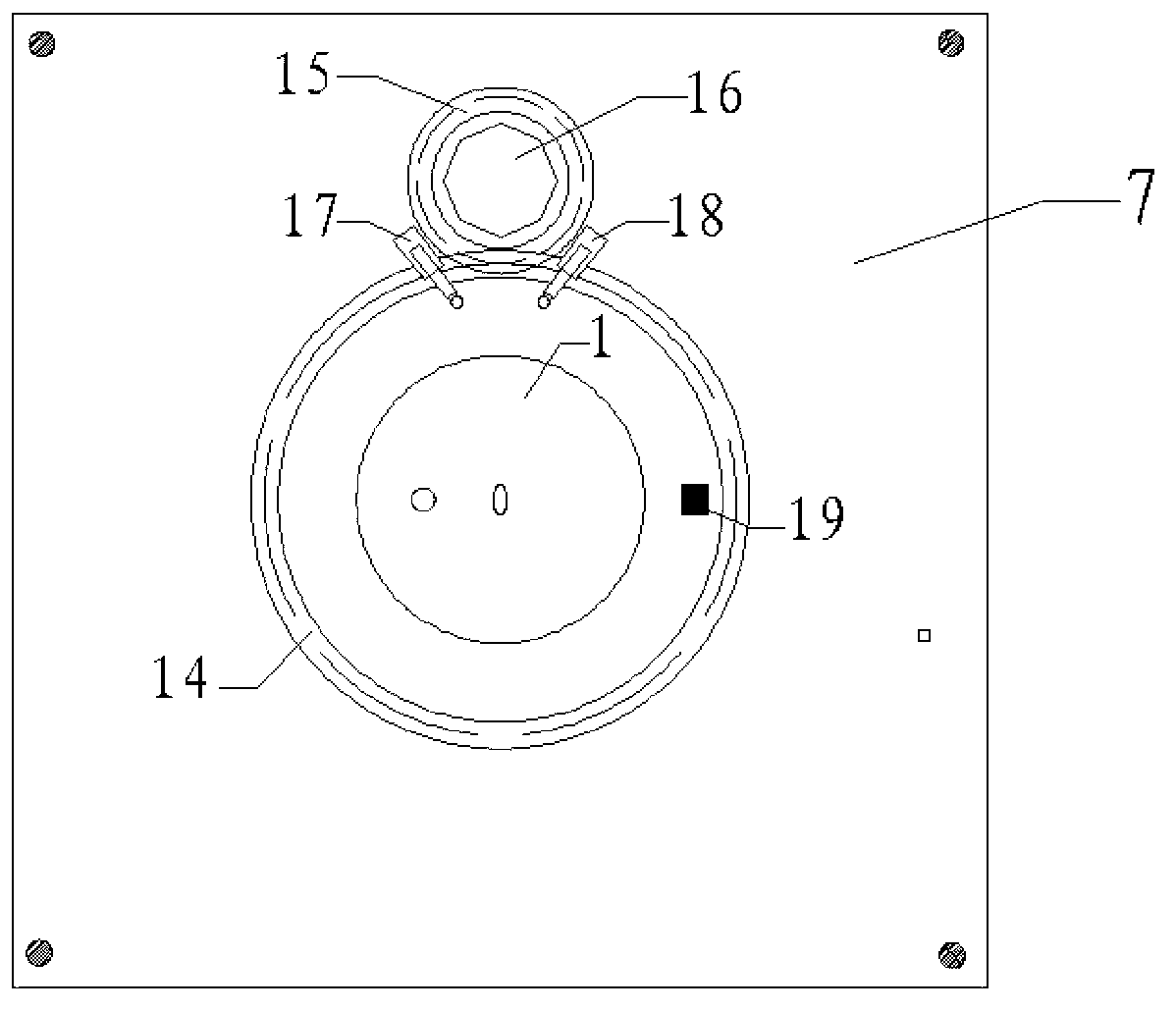

[0030] The automatic rotating and lifting monitoring system for ash accumulation and slagging in the coal power plant boiler furnace of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as figure 1 and figure 2 As shown, an automatic rotating and lifting monitoring system for ash accumulation and slagging in the furnace of a coal power plant boiler includes: a fixed bracket 9, a lifting platform 7 slidingly matched with the fixing bracket 9, and an imaging system installed on the lifting platform 7; A cooling device outside the imaging system, the bottom of the cooling device is provided with an observation port 32; a driving mechanism for driving the imaging system to rotate; a circuit control box 13; and a display connected to the imaging system.

[0032] The imaging system is composed of a CCD camera 1 and an electrically adjustable optical lens 3. The CCD camera 1 is provided with a camera shield 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com