Full automatic production line of board to board (BTB) connector

A connector and production line technology, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the problems of long time, no flow operation, and difficult to achieve quantification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

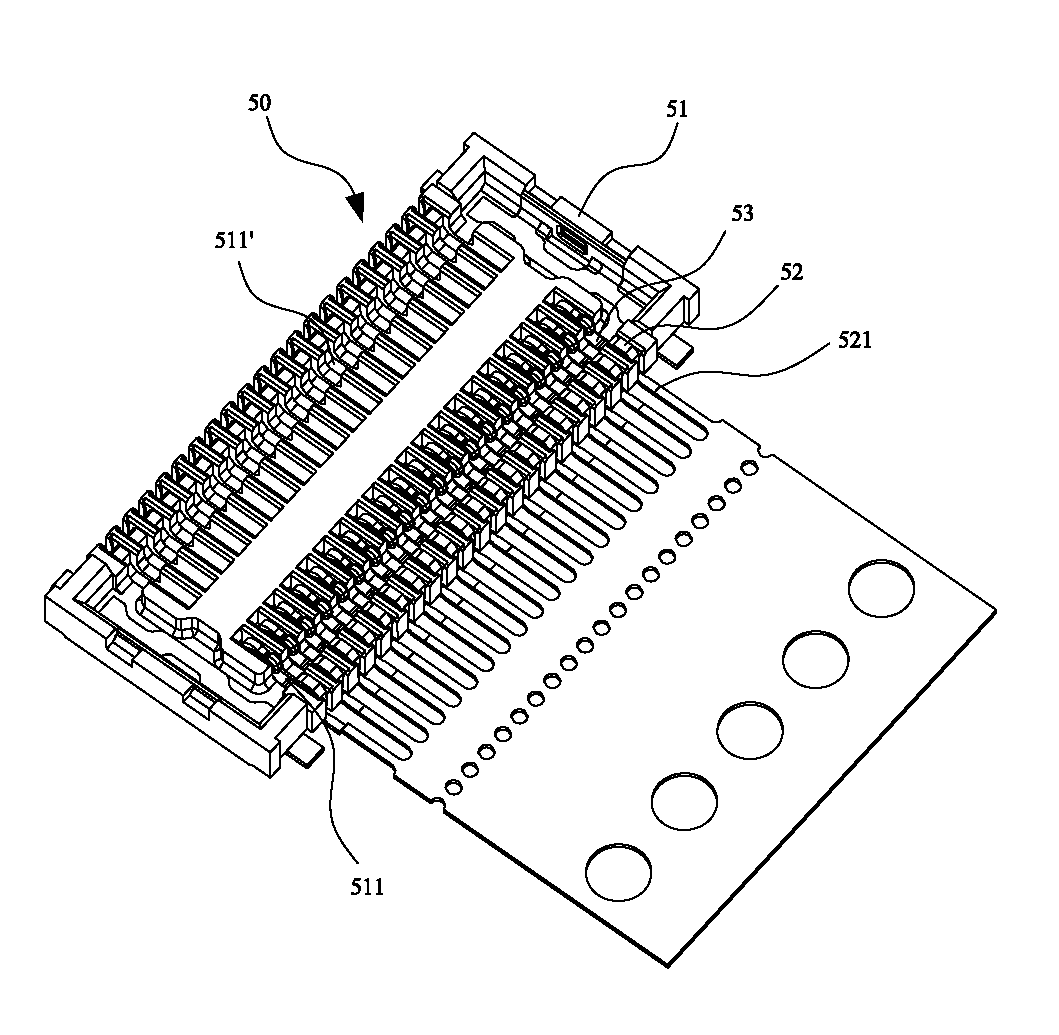

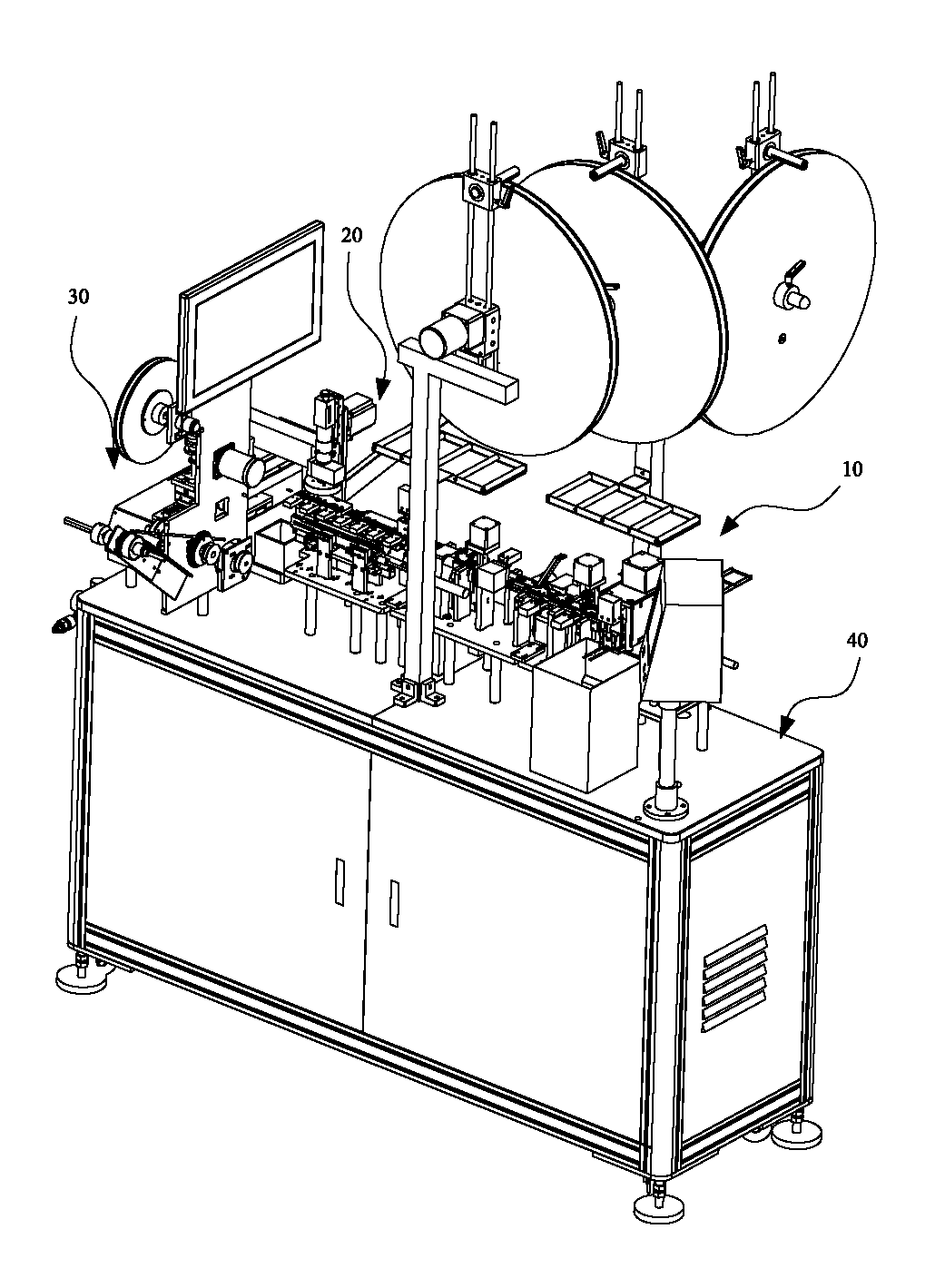

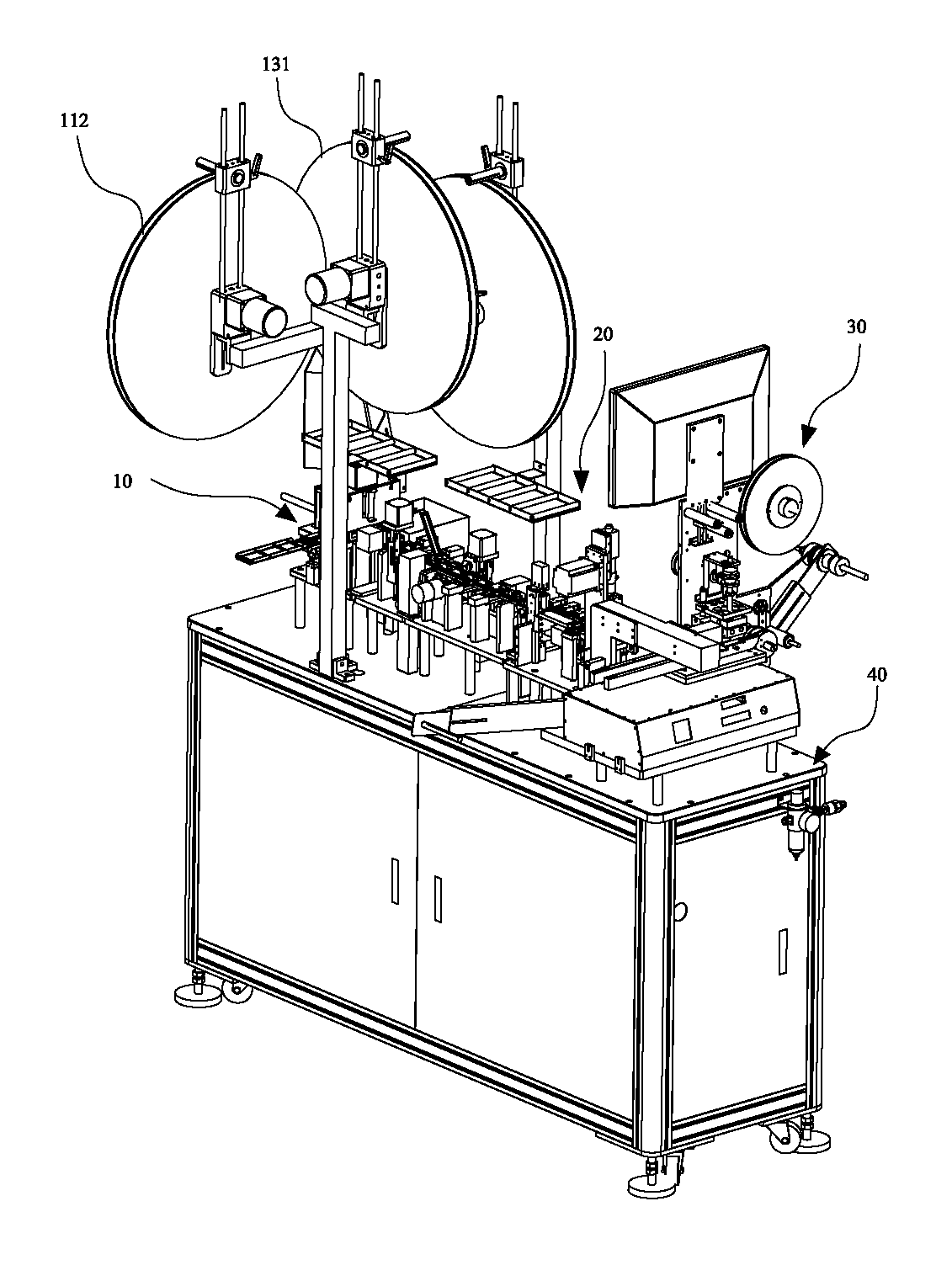

[0098] Please refer to Figure 2 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, the BTB connector 50 automatic production line includes product assembly molding part 10, product testing part 20 and product packaging part 30, these three major parts are arranged in sequence On the machine platform 40 of the production line, for example figure 1 The BTB connector shown is produced.

[0099] First of all, the up, down, left, right, front and back directions mentioned in the text and Figure 5 and Figure 6 The marked direction shall prevail.

[0100] among them, see Figure 4 , Figure 5 , for the product assembly molding part 10, there are a first starting station A and a first finishing station B on the machine table 40 of the production line, and the spacing between the first starting station A and the first finishing station B is successively Distributed with plastic body feeding station C, first terminal feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com