Method for applying liquid crystal display panel border adhesive

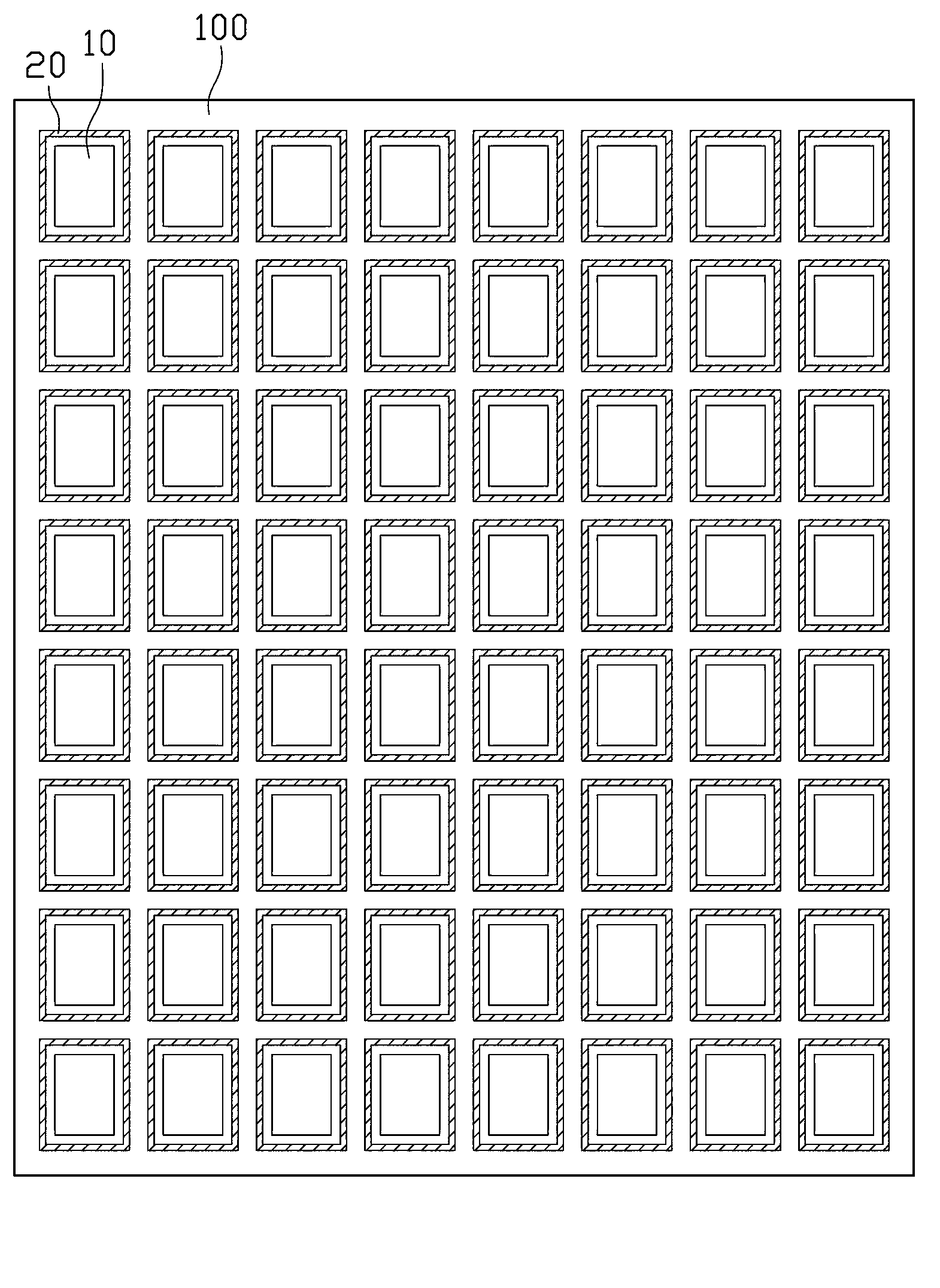

A coating method and technology for liquid crystal panels, which can be applied to devices, coatings, optics and other directions for coating liquid on the surface, and can solve problems such as leakage of liquid crystals, image chromatic aberration, and poor cutting of liquid crystal cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

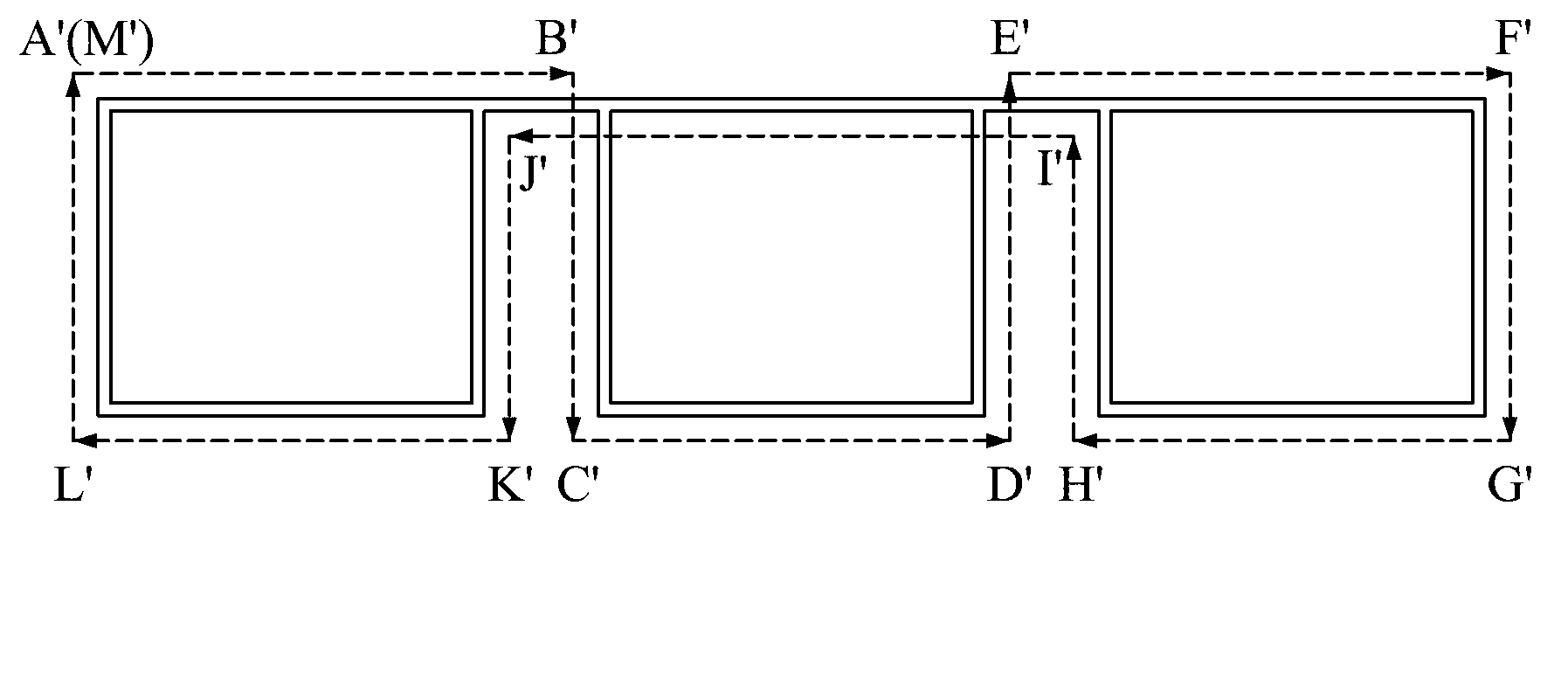

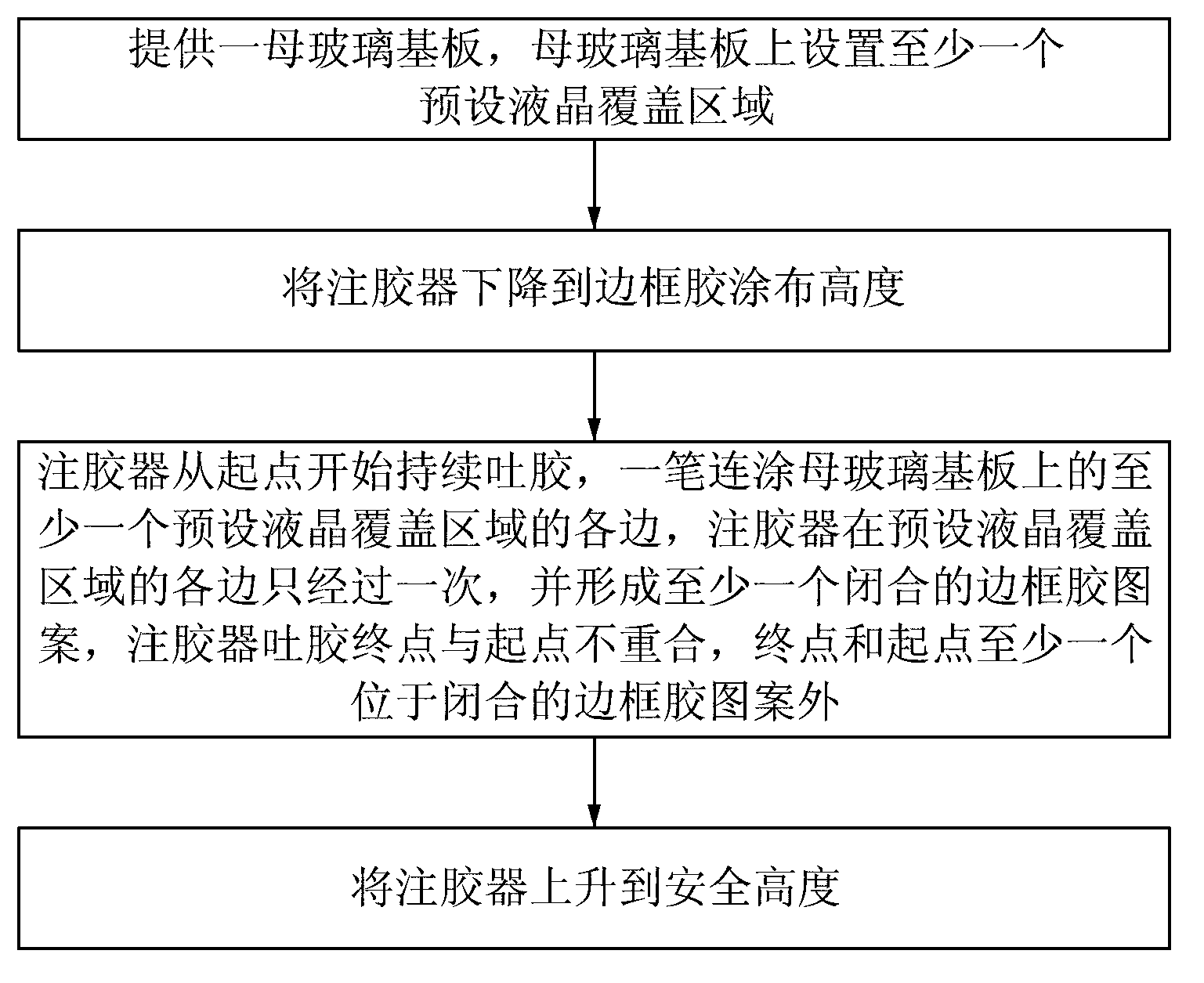

[0032] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods, methods and steps of the coating method for the frame glue of the liquid crystal panel proposed according to the present invention And effect, detailed description is as follows.

[0033] The invention proposes a liquid crystal panel frame glue coating method, image 3 Show the flow chart of liquid crystal panel frame glue coating method of the present invention, please refer to image 3 , whose steps include:

[0034] (1) A mother glass substrate is provided, and at least one preset liquid crystal coverage area is set on the mother glass substrate.

[0035] (2) Lower the glue injector to the coating height of the frame glue. The glue injector is filled with colloid, move the glue injector or move the mother glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com