Linear transmission part with lubricating oil recovery module

A technology of linear transmission and lubricating oil, which is applied in the direction of lubricating parts, transmission devices, engine components, etc., and can solve the problems of lubricating oil spillage and pollution of linear components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

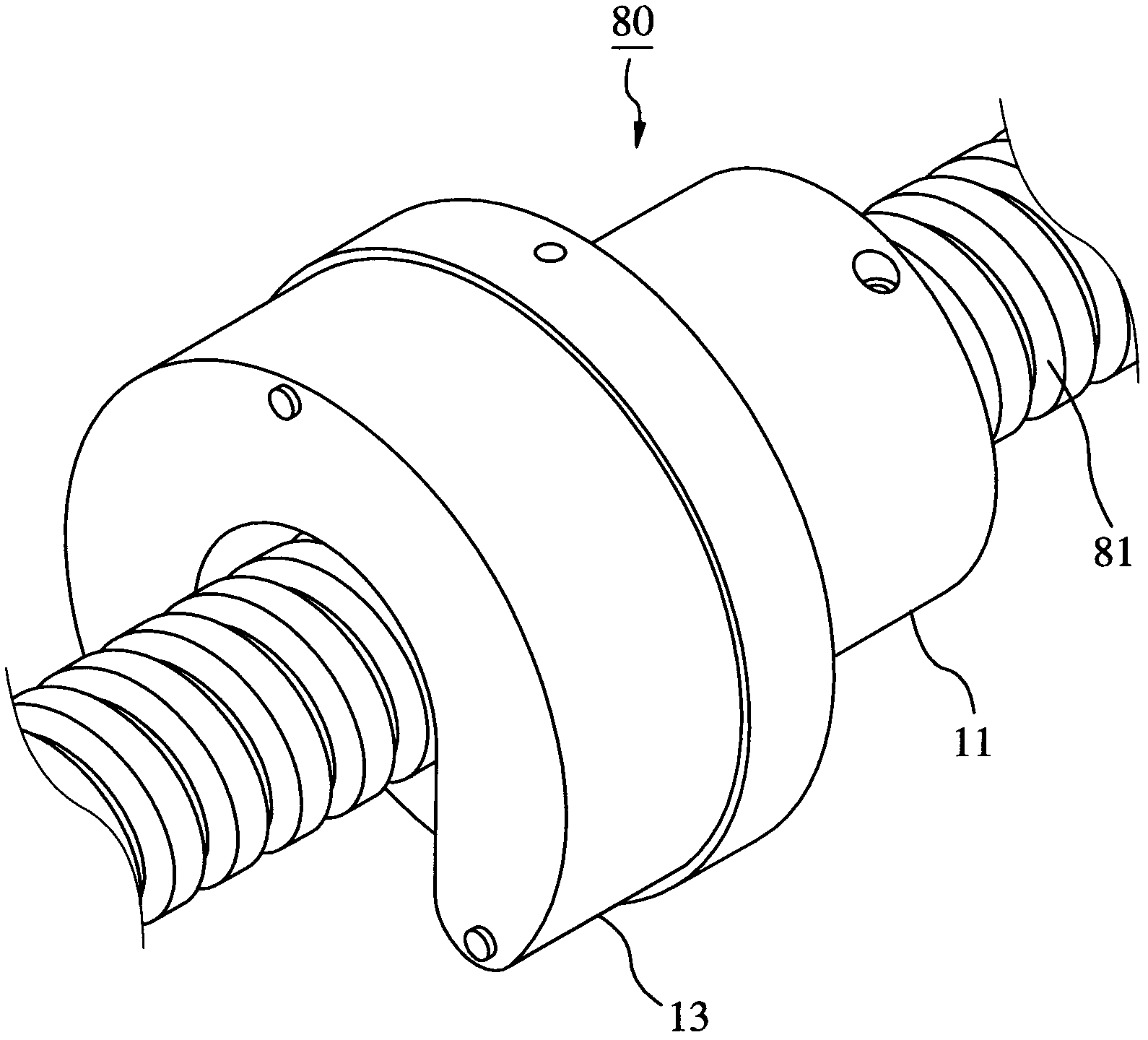

[0024] like Figure 1-Figure 7 As shown, a linear transmission part with a lubricating oil recovery module in the present invention is composed of a long shaft 81 to form a linear element 80. The linear transmission part mainly includes: a moving body 11, a first oil core 12, An oil tank 13 , a second oil core 14 and a third oil core 15 . It should be stated here that the figure 1 The linear element 80 shown in is a screw nut set, while in figure 2 The middle part shows the linear slide rail set, and in the preferred embodiment of the present invention, the screw nut set and the linear slide rail set are taken as examples for illustration.

[0025] The moving body 11 is disposed on the long axis 81 and can reciprocate relative to the long axis 81 . The moving body 11 has a chamber 111 .

[0026] The first oil wick 12 is installed in the moving body 11 and the chamber 111, the first oil wick 12 has a first oil absorption section 121 and a first oil outlet section 122, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com