Helical-tooth-type concrete wall block

A concrete wall and concrete technology, which is applied in the direction of building components, earthquake resistance, construction, etc., can solve the problems of non-occlusion of blocks, personal casualties, etc., and achieve the effect of no increase in cost, improvement of disaster reduction and earthquake resistance, and continuous and rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing

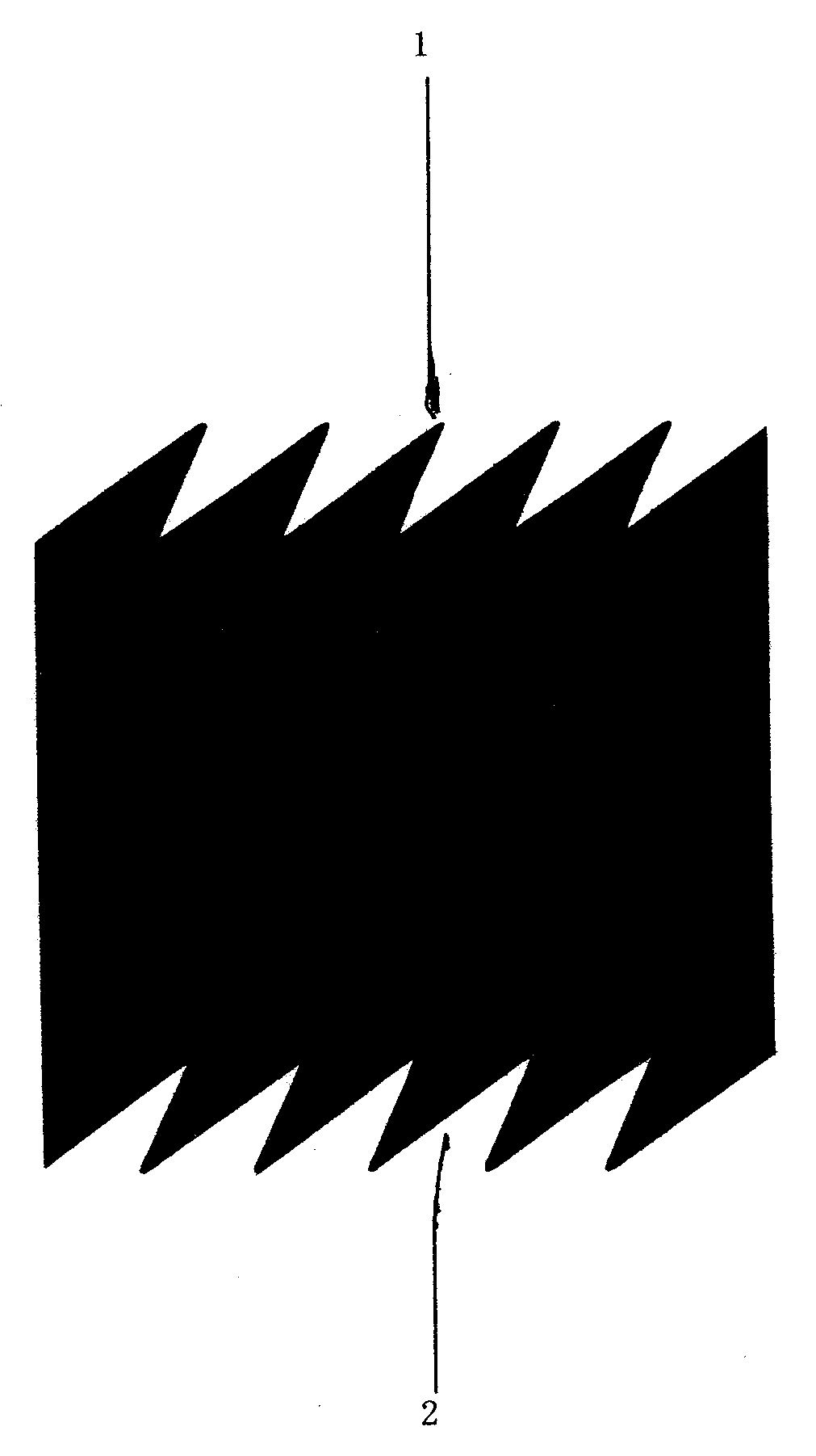

[0012] In the figure, block helical tooth type 1. Helical tooth type block helical tooth type occlusion 2. During construction, helical tooth type 1 and another block helical tooth type occlusion 2 are put together, and then filled with mortar and cement The gap is full, so that each helical-toothed block can be tightly snapped together, so that the entire concrete wall is snapped together, and the entire house and building become a whole, and the house structure is firm. Therefore, the ability of earthquake resistance and disaster reduction has been greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com