Host machine of track-laying machine improved based on replacement structure, and assembly method thereof

A technology of structure improvement and assembly method, which is applied in the direction of laying track, track, track maintenance, etc., to achieve the effect of reducing labor intensity, reducing safety hazards, and saving adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

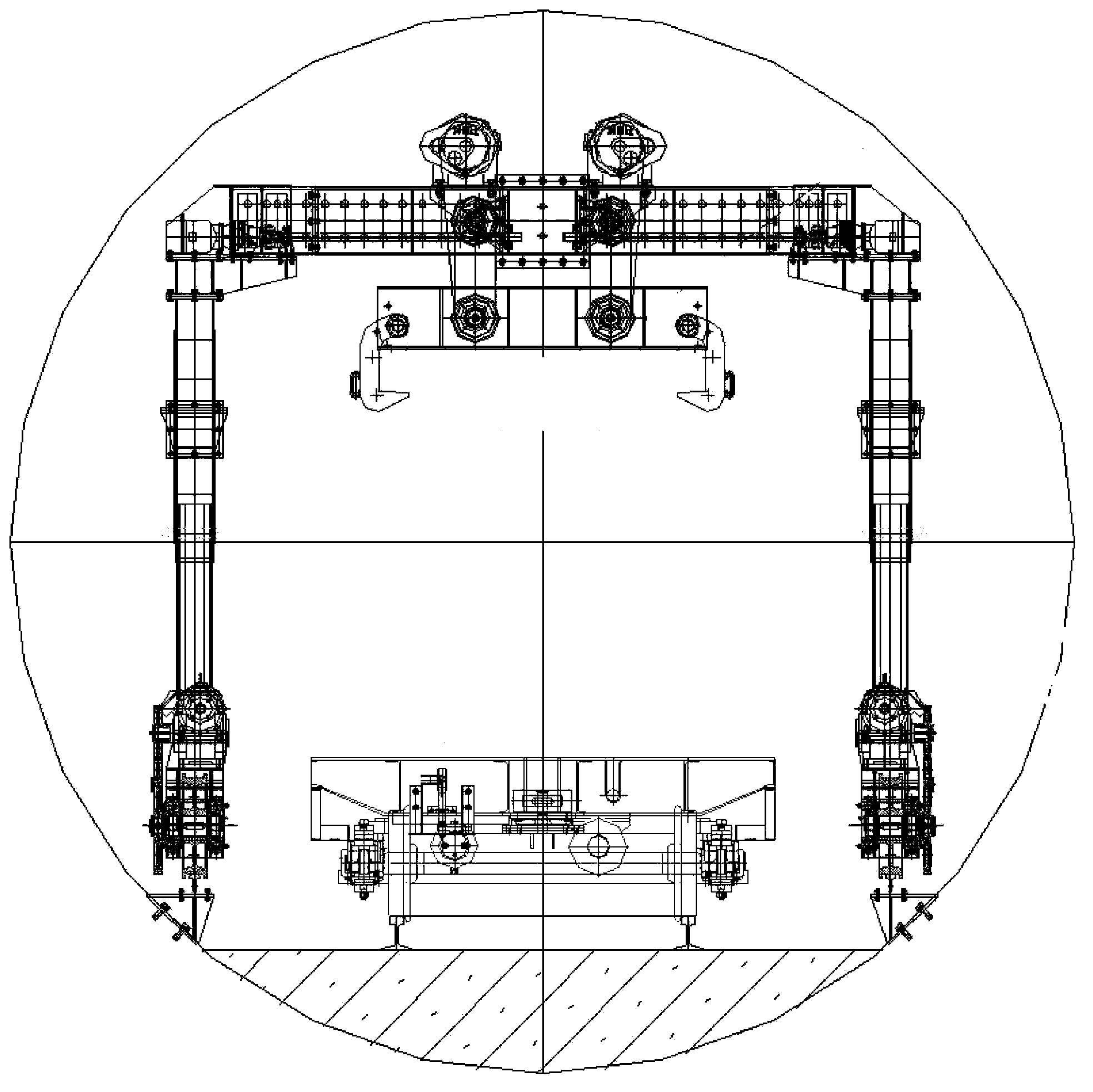

[0044] The track laying machine applied in this embodiment is composed of three parts: guide sleeve, traverse mechanism assembly and guide column type upper beam, and its structure is described in turn:

[0045] Guide sleeve such as Figure 5 , 6 , 7, it is mainly composed of a cover plate 51, a bottom plate 52, a web 53, a reinforcing plate 54, and ribs 55, 56. The guide sleeve is a hollow cuboid structure with missing corners, and the cuboid is an upper narrow Lower wide structure, cover plate 51 is positioned at the top of cuboid, base plate 52 is positioned at the bottom of cuboid, and web 53 is positioned at the cavity interior of cuboid and vertical bottom plate 52 is placed, and the side of guide sleeve is also provided with ribs 55,56.

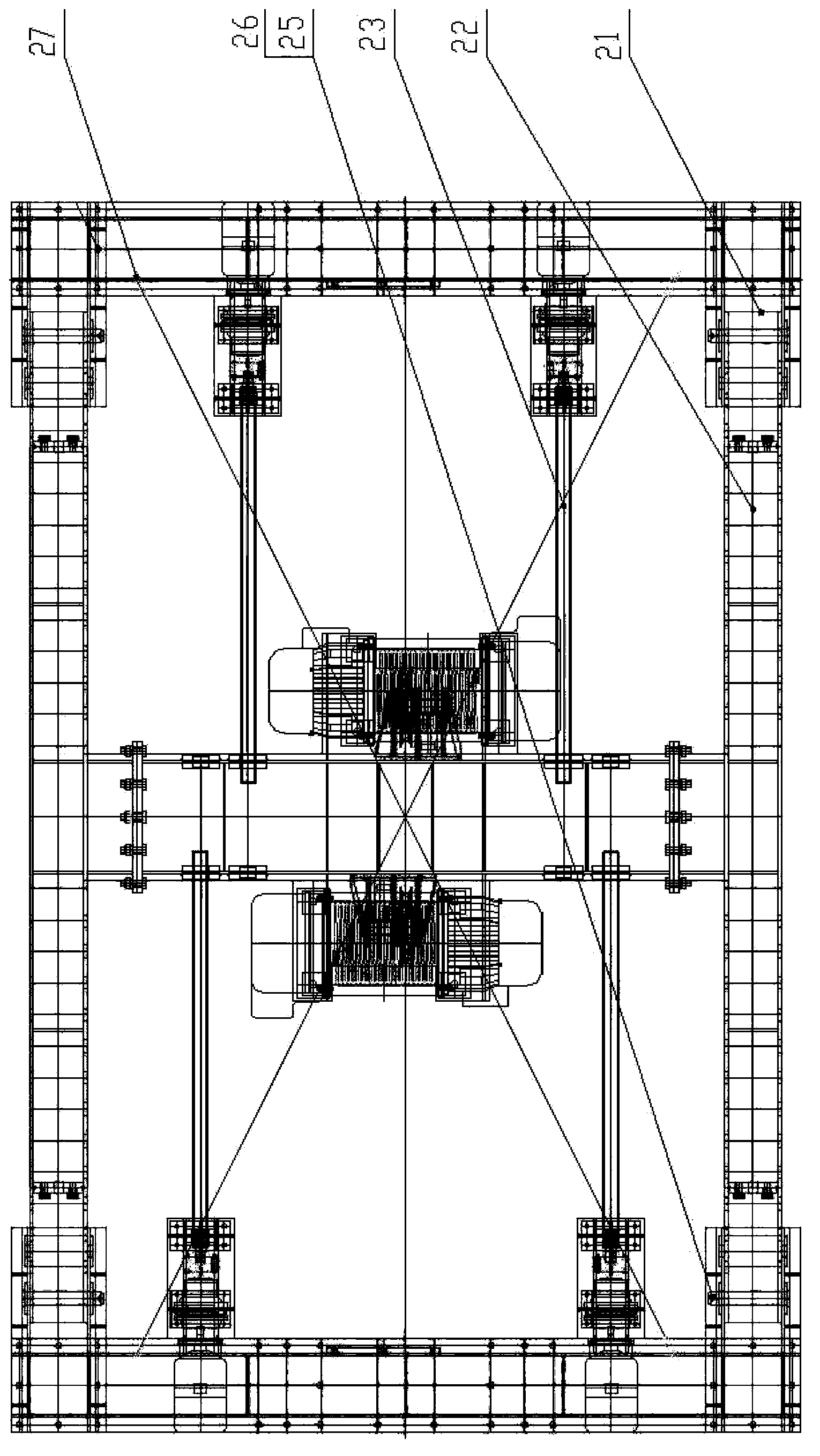

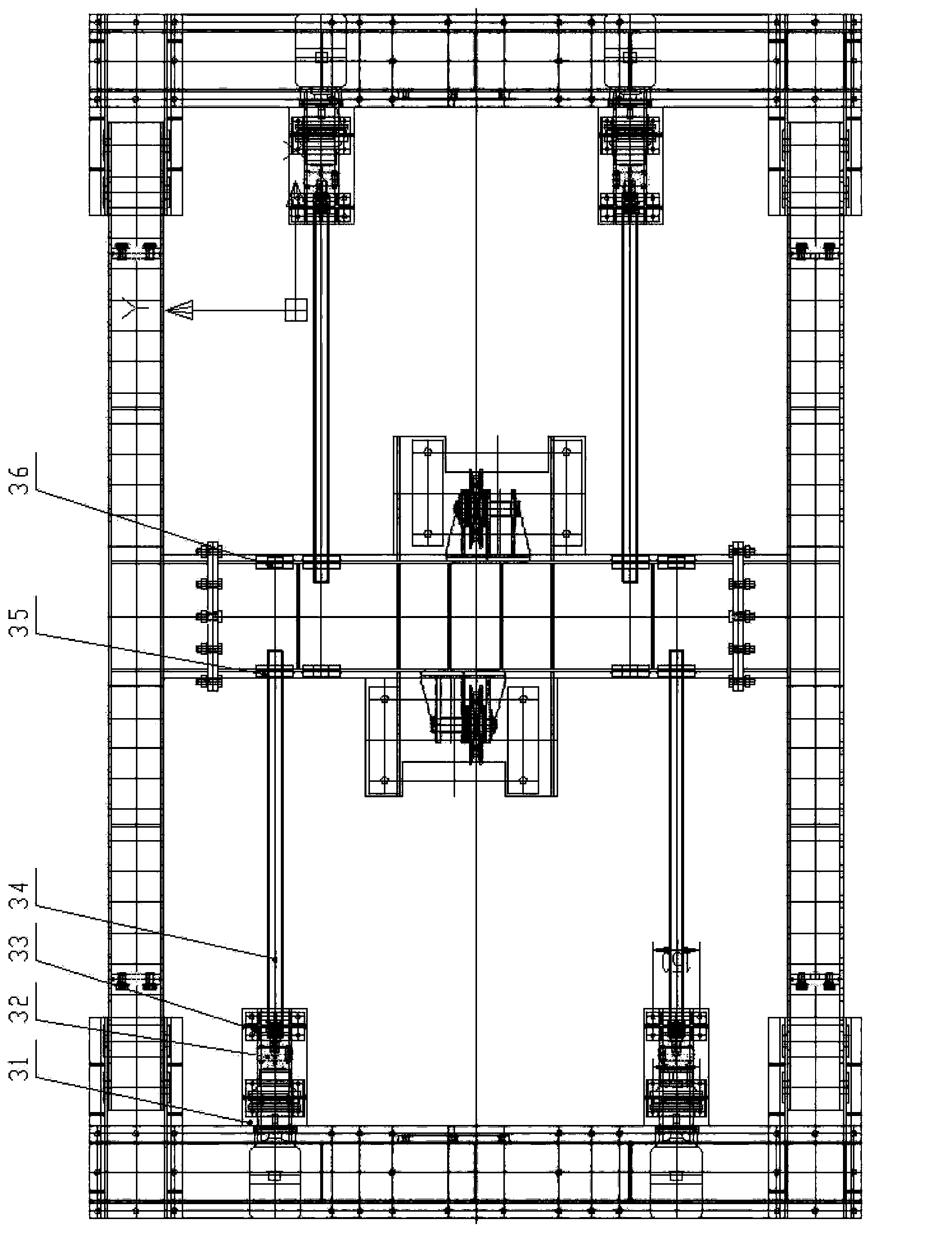

[0046] As shown in Figure 3(a) and Figure 3(b), the traversing mechanism assembly mainly consists of a traversing support 31, a coupling 32, a bearing seat 33, a traversing lead screw 34, a traversing nut 35, a traversing Shift guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com