Spinning unit and spinning machine

A spinning unit and spinning technology, applied to spinning machines, open-end spinning machines, continuous winding spinning machines, etc., can solve malfunctions, changes in spinning characteristics, malfunctions of air actuators, etc. problems, to achieve the effect of easy maintenance and preventing positional misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

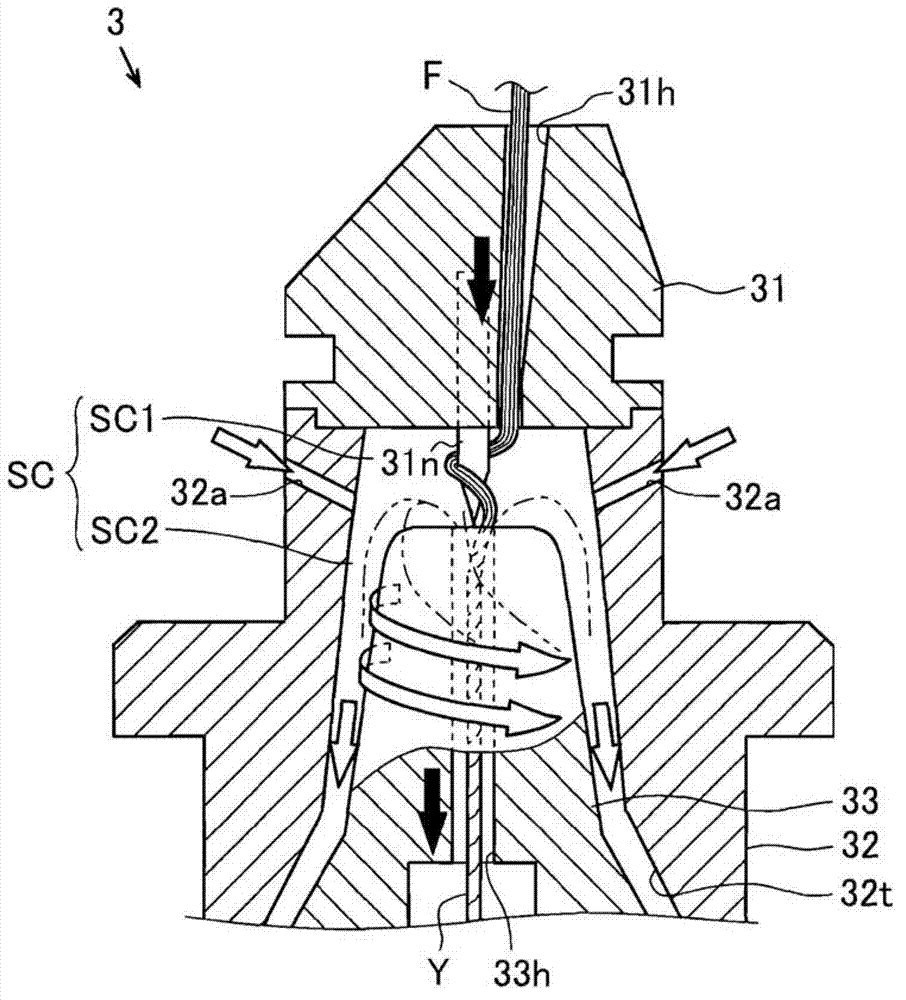

[0036] First, the overall structure of the spinning unit 100 will be briefly described. figure 1 The shown black arrows indicate the feeding directions of the fiber bundle F and the spun yarn Y. The spinning unit 100 is a spinning machine that produces a spun yarn Y from a fiber bundle F to form a package P. The spinning unit 100 includes a sliver supply unit 1, a draft unit 2, a spinning unit 3, a yarn defect detection unit 4, a tension stabilizing unit 5, and a winding unit 6 along the feeding direction of the fiber bundle F and the spun yarn Y.

[0037] The sliver supply unit 1 supplies the fiber bundle F (sliver) to the draft unit 2 . The sliver supply unit 1 includes a creel 11 and creels (not shown). The fiber bundle F stored in the creel 11 is guided by the creel and guided to the drafting unit 2 .

[0038] The drafting unit 2 drafts the fiber bundle F to make the thickness of the fiber bundle F uniform. The drafting unit 2 includes four sets of drafting roller pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com