Method for treating semiconductor technology wastewater

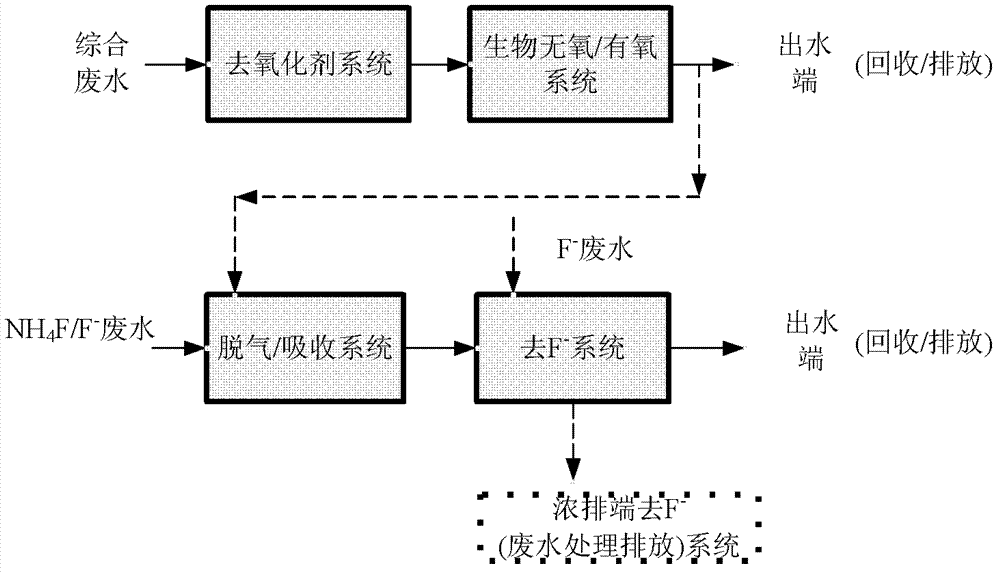

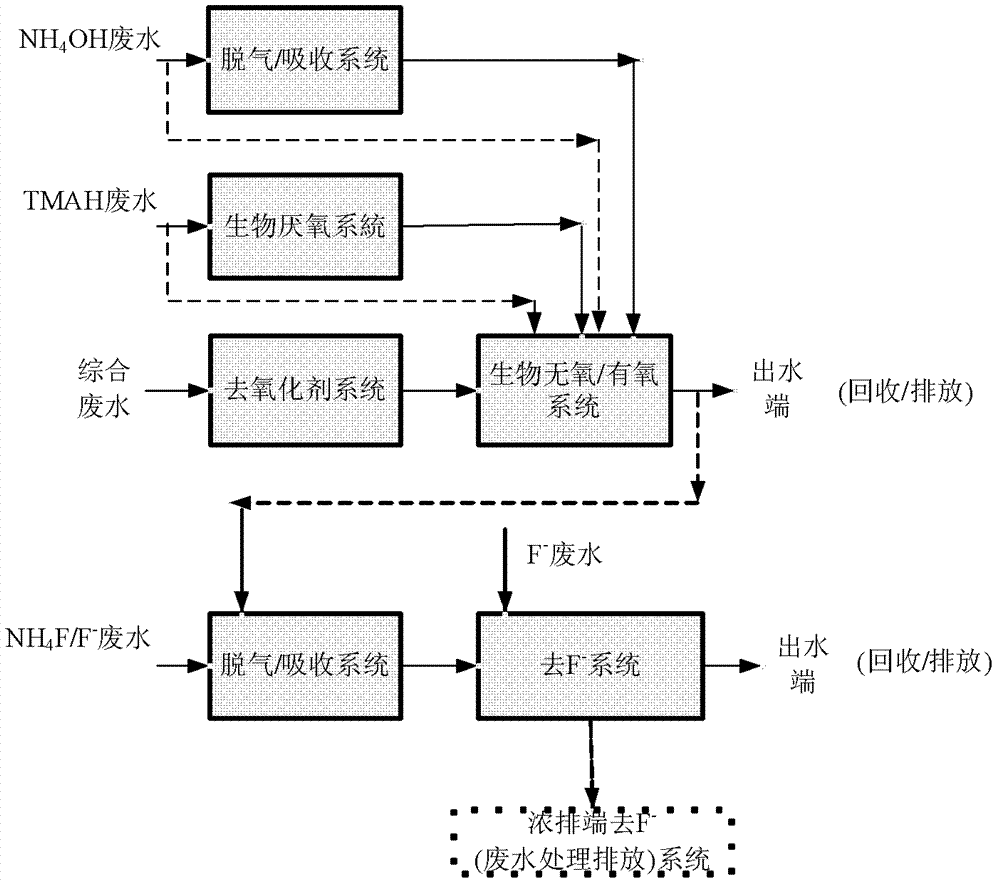

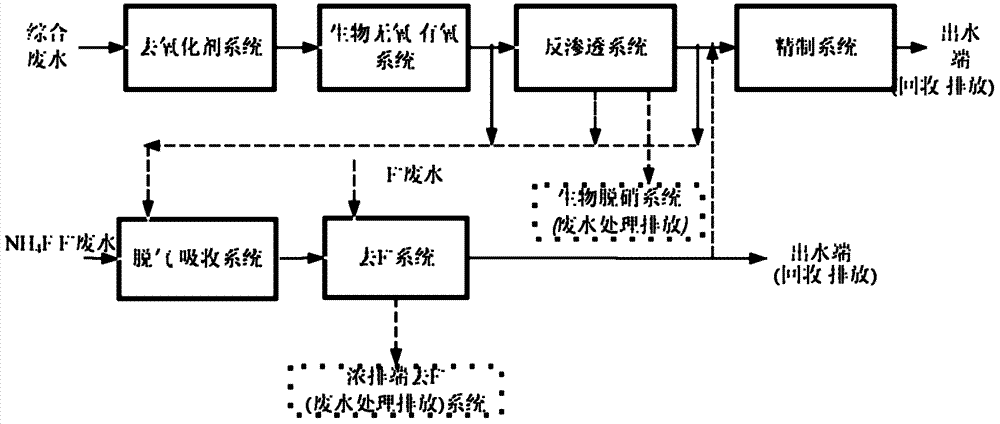

A semiconductor and wastewater technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve problems such as semiconductor process wastewater treatment methods that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: De-oxidizing system test

[0037] 1.H 2 o 2 Remove test data with dosing sodium sulfite

[0038] The test was carried out in continuous operation, and the concentration of the influent wastewater is shown in Table 2. The test process and operating parameters of the mold factory: dosing sodium sulfite, the dosing amount is 1.2 times the theoretical value, so that the H 2 o 2 Down to <5ppm (test time 200 hours). The description of the water quality after treatment by the deoxidizing system is shown in Table 2.

[0039] Table 2, H 2 o 2 Remove test data with dosing sodium sulfite

[0040]

[0041] From the data in Table 2, it can be seen that the oxidant removal system with dosing can be used to effectively remove H from this complex wastewater 2 o 2 oxidizing agent.

[0042] 2.H 2 o 2 Catalyst removal of test data

[0043] a. With MnO 2 test

[0044] The test was carried out in continuous operation, and the concentration of wastewater at the ...

Embodiment 2

[0063] Example 2: Process testing of oxidant removal system, biological aerobic / anaerobic system and reverse osmosis system

[0064] 1. Test data of deoxidizing system + biological aerobic system (tested with monomer)

[0065] The test was carried out in continuous operation, and the concentration of wastewater at the water inlet is shown in Table 6. The test process and operating parameters of the mold factory: firstly add sodium sulfite to make H 2 o 2 Reduce to <40ppm, and adjust the pH value to 6.8; there are monomers in the biological aerobic tank (residence time 12 hours). The water quality after biological aerobic tank treatment is shown in Table 6.

[0066] Table 6. Test data of deoxidizing system + biological aerobic system (tested with monomer)

[0067]

[0068]

[0069] 2. Deoxidant system + biological anaerobic / aerobic system (tested with biofilm) + reverse osmosis system test data

[0070] The test was carried out in continuous operation, and the concen...

Embodiment 3

[0076] Example 3: Degassing / Absorptive System Testing

[0077] The test was carried out in continuous operation, and the concentration of wastewater at the water inlet is shown in Table 8. Model factory test process and operating parameters: First, the wastewater is adjusted to a pH value of 11.5 in a pH tank, and then introduced into a degassing tank where the air is blown from the bottom at a ratio of air to water flow rate of 1000:1, degassing The wastewater residence time of the tank was 1.2 hours. NH 4 The ammonia nitrogen degassing efficiency of OH wastewater is 80%. The description of the effluent quality is shown in Table 8. The ammonia-containing air coming out of the liquid surface is sent to an absorption tank, and the ammonia gas (product ammonium phosphate) is absorbed with phosphoric acid aqueous solution.

[0078] Table 8. Degassing / Absorptive System Tests

[0079]

[0080]

[0081] The data in Table 8 shows that other species in the wastewater will n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com