Double-circulation anaerobic reactor

An anaerobic reactor, double-circulation technology, applied in the field of anaerobic reactor, can solve the problems of inability to apply high-concentration water quality and biodegradability, slow growth of granular sludge, short hydraulic retention time, etc., and meet the PH value of the influent water. The effect of loose, fast growth of granular sludge and stable effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

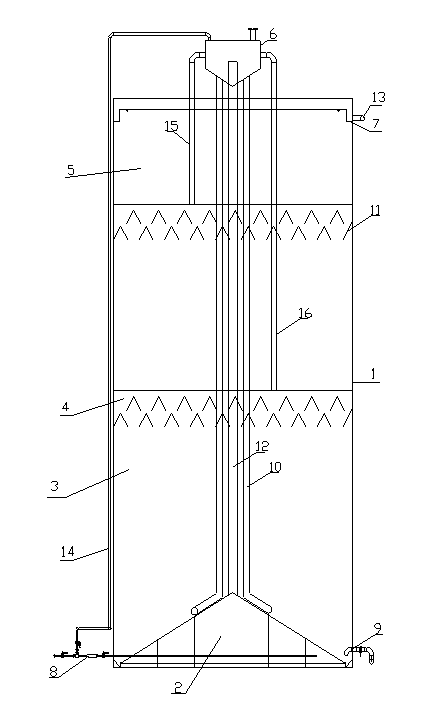

[0010] As shown in the accompanying drawings, the double-cycle anaerobic reactor of the present invention mainly includes a pool body 1, the pool body 1 adopts a steel structure, and the entire structure is columnar, which is a multi-region and multi-functional combination. The tank body 1 is divided into conical sludge expansion zone 2, main reaction zone 3, secondary reaction zone 11 and sedimentation zone 5 from bottom to top. The upper part of zone 11 is provided with a secondary gas-solid-liquid separation zone, and the upper and lower gas-solid-liquid separation zones are both equipped with three-phase separators. The conical sludge bulking zone 2 is a conical hood, and an airlift pipe 12 is connected to the conical hood. An outlet weir 7 is arranged above the settling area 5 , and an outlet pipe 13 is arranged on the outlet weir 7 .

[0011] The top of the pool body 1 is provided with a dual-circulation reflux system, which includes a stripping pipe 12, a gas-water sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com