Device for storing multiple types of particles

An access device, a technology for granular materials, applied in the direction of powder material distribution, etc., can solve the problems of inconvenient storage, removal, placement, inconvenience in taking grains, inconvenient storage, etc., and achieves flexible and convenient rotation, simple structure, and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

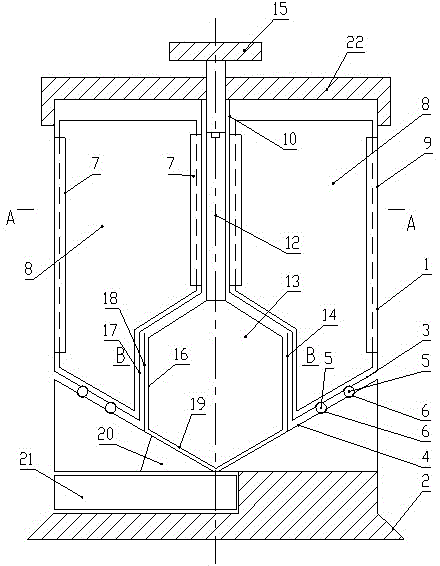

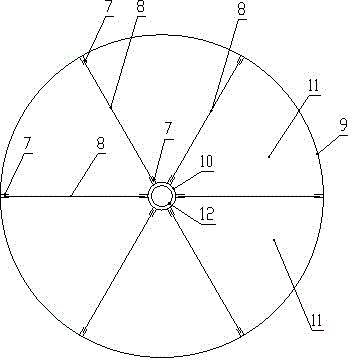

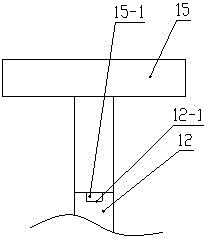

[0027] Such as figure 1 As shown, the present invention includes a base 2 and a cylinder 1, the cylinder 1 is located above the base 2, the base 2 is approximately cylindrical (its cross-sectional shape can also be a polygonal column shape), and the upper end is provided with a concave conical surface 4; The body 1 is also cylindrical, and its diameter matches the diameter of the base 2 . Its lower end is a protruding conical protrusion 3 . Two circles of balls 5 are evenly arranged on the concave conical surface of the base 2 (several more circles can be set according to the actual situation), and each circle of balls 5 is evenly arranged along the circumferential direction, generally 3 or more, corresponding to the conical Two rings of raceways 6 are arranged on the conical surface of the protrusion 3 . The raceway 6 rolls on the ball 5 and rotates back and forth around the center line of the cylinder 1 . The raceways 6 and the balls 5 can be approximately replaced as foll...

Embodiment 2

[0037] Such as Figure 6 As shown, the difference from Embodiment 1 is that the present invention also includes an adjustment device 23, the adjustment device 23 includes an adjustment rod 24 and an adjustment cover 25 connected to the lower end of the adjustment rod 24, and the adjustment cover 25 is a hollow cylinder with a downward opening. , its outer diameter should be less than the inner diameter of the feed bin 13. The lower edge of the adjustment cover 25 is located between the upper and lower edges of the inlet 16 of the bin. Turning bar 12 is a hollow bar, and regulating bar 24 passes in handle 15 and rotating bar 12, moves regulating cover 25 up and down, can partly block and get bin entrance 16, changes the grain amount that enters getting bin 13.

[0038] In addition, a circle of snap grooves 26 can be set around the base 2, and a circle of snap rings 27 can be set correspondingly around the bottom of the cylinder body 1. When the cylinder body 1 is rotating, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com