Follow-up support device

A supporting device and follow-up technology, which is applied in the directions of ground installation, transportation and packaging, and aircraft component testing, etc., can solve the problems of not being able to limit the deformation of the test piece, affecting the effectiveness of the test, and the safety of the test piece, so as to achieve reliability assurance and support Accurate status and improved test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

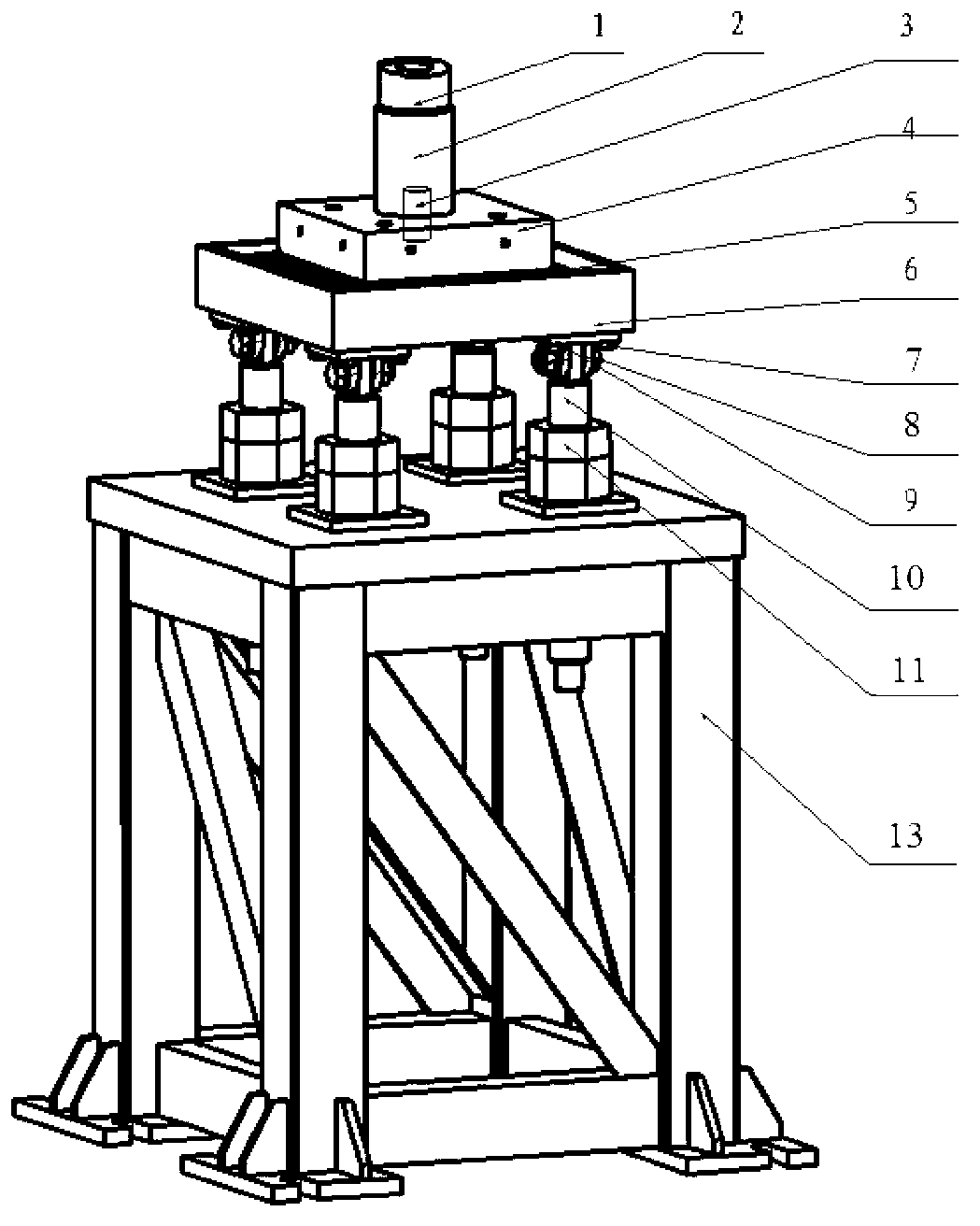

[0021] Such as figure 1 , figure 2 , image 3 As shown, the follow-up support device of the present invention includes special parts 1, a sensor 2, a connecting screw 3, a moving plate 4, a ball device 5, a fixing plate 6, a binaural fixing screw 7, a binaural 8, a hinge screw 9, and an adjusting screw 10. , The upper end adjusting nut 11, the lower end adjusting nut 12, and the mounting base 13. The ball device is composed of steel balls 14 and steel ball brackets 15. The special piece 1 is a cylindrical structure for screwing with the upper end of the sensor 2. The lower end of the sensor 2 and the upper end of the moving plate 4 are screwed together by a connecting screw 3, and the moving plate 4 and the fixed plate 6 are supported by steel balls 14 arranged in a matrix. The steel ball 14 is placed in the steel ball mounting groove / hole of the steel ball bracket 15 to ensure that the relative position of the steel ball 6 remains unchanged when the flat rolling bearing is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com