Axle arrangement having a de-coupling device

A technology of axles and connecting devices, which is applied to vehicle parts, transportation and packaging, suspensions, etc., can solve the problems of high cost of sub-frame structures, and achieve the effect of firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the drawings, the same reference numerals are used for the same or similar components, although repeated descriptions are omitted for brevity.

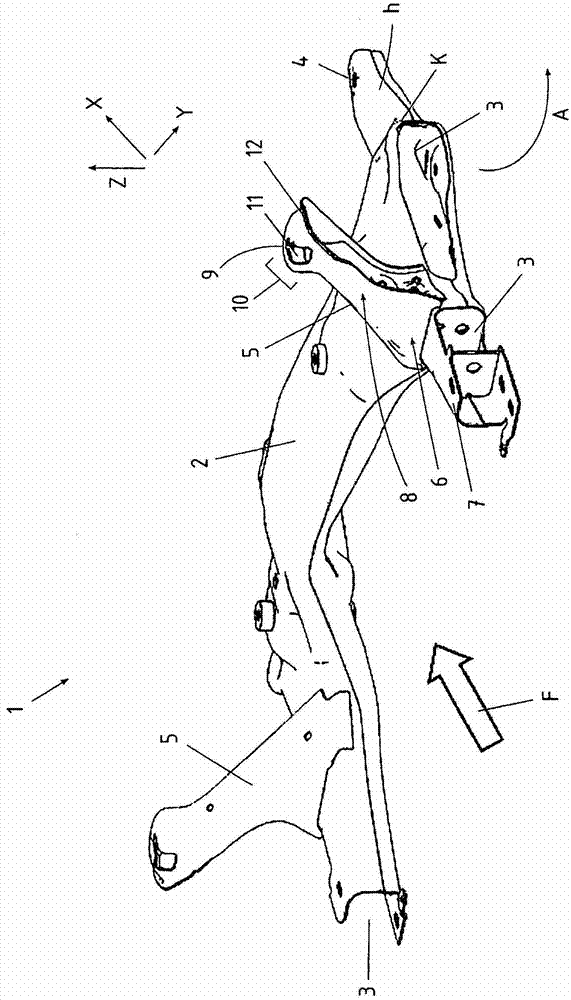

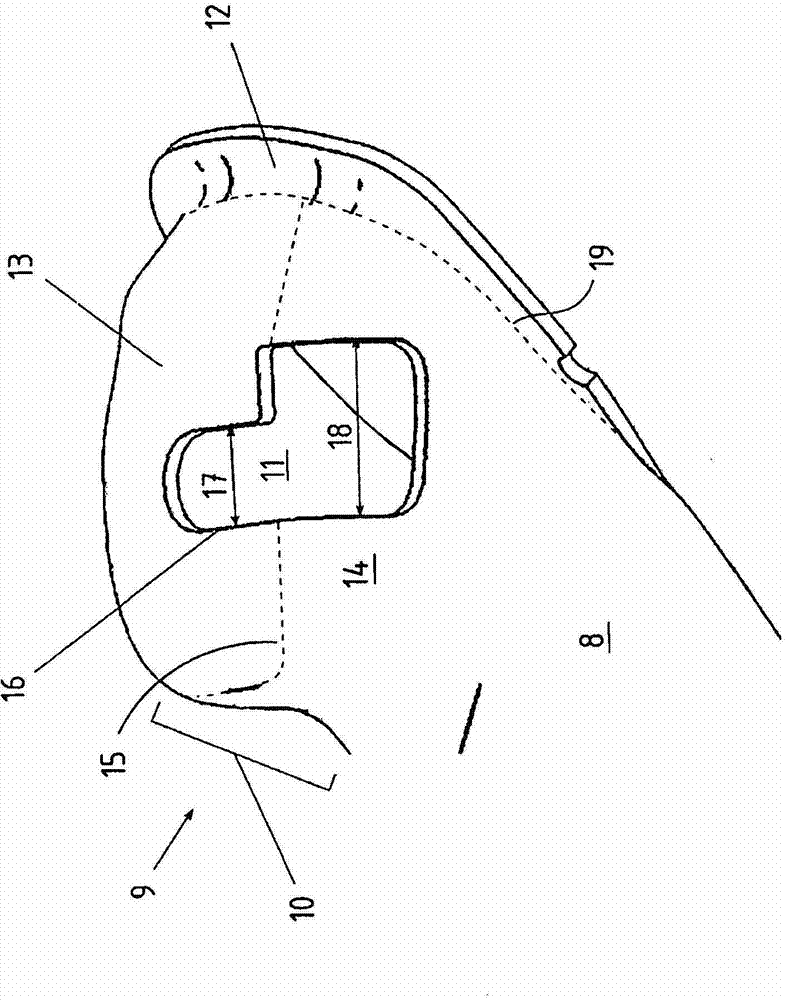

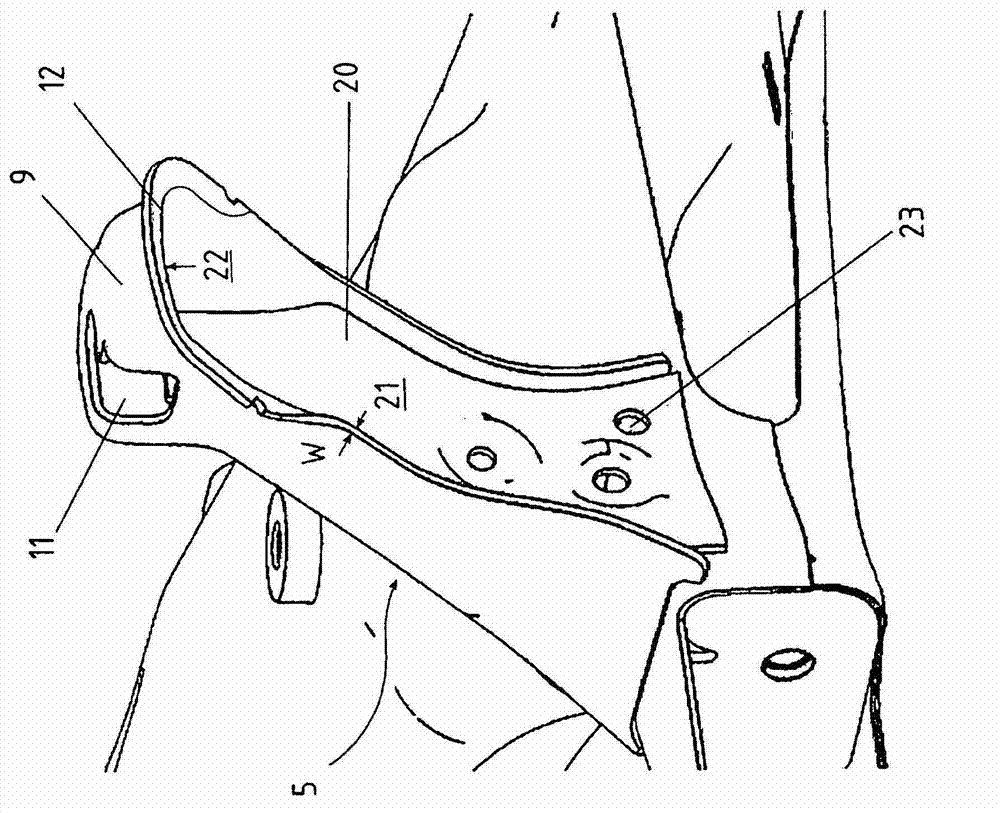

[0035] figure 1 A perspective view of an axle device 1 with an axle subframe 2 according to the invention is shown. A coupling position 3 for connecting a suspension arm not shown in detail here is provided on the axle subframe 2. The entire axle device 1 is coupled to a vehicle body not shown in detail from below. To this end, a plurality of connection locations 4 are provided on the axle subframe 2 and are connected to different corresponding locations of the vehicle body. In addition, figure 1 The rear body connecting device h is shown, which extends as an extension of the axle subframe 2. A predetermined bending position K is provided between the rear body connecting device h and the axle sub-frame 2. In the event of a collision, the axle sub-frame 2 moves downwards around the predetermined bending position A to move to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com