Printer

A technology for printers and print heads, applied in printing devices, printing and other directions, can solve problems such as damage to print heads, circuit board sensing elements, printing paper damage, printer damage, etc., to achieve beautiful appearance, small footprint, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] Embodiments of the present invention are described in detail below:

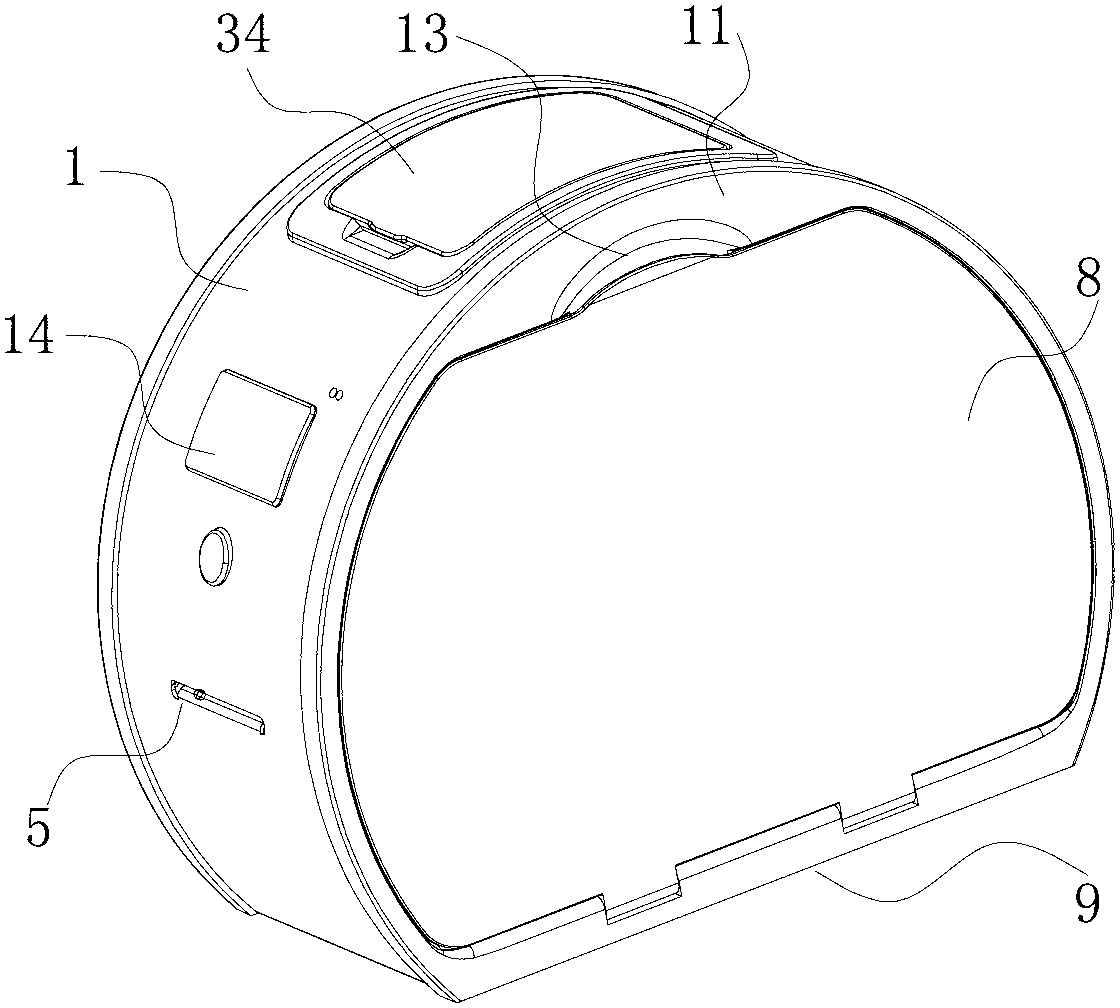

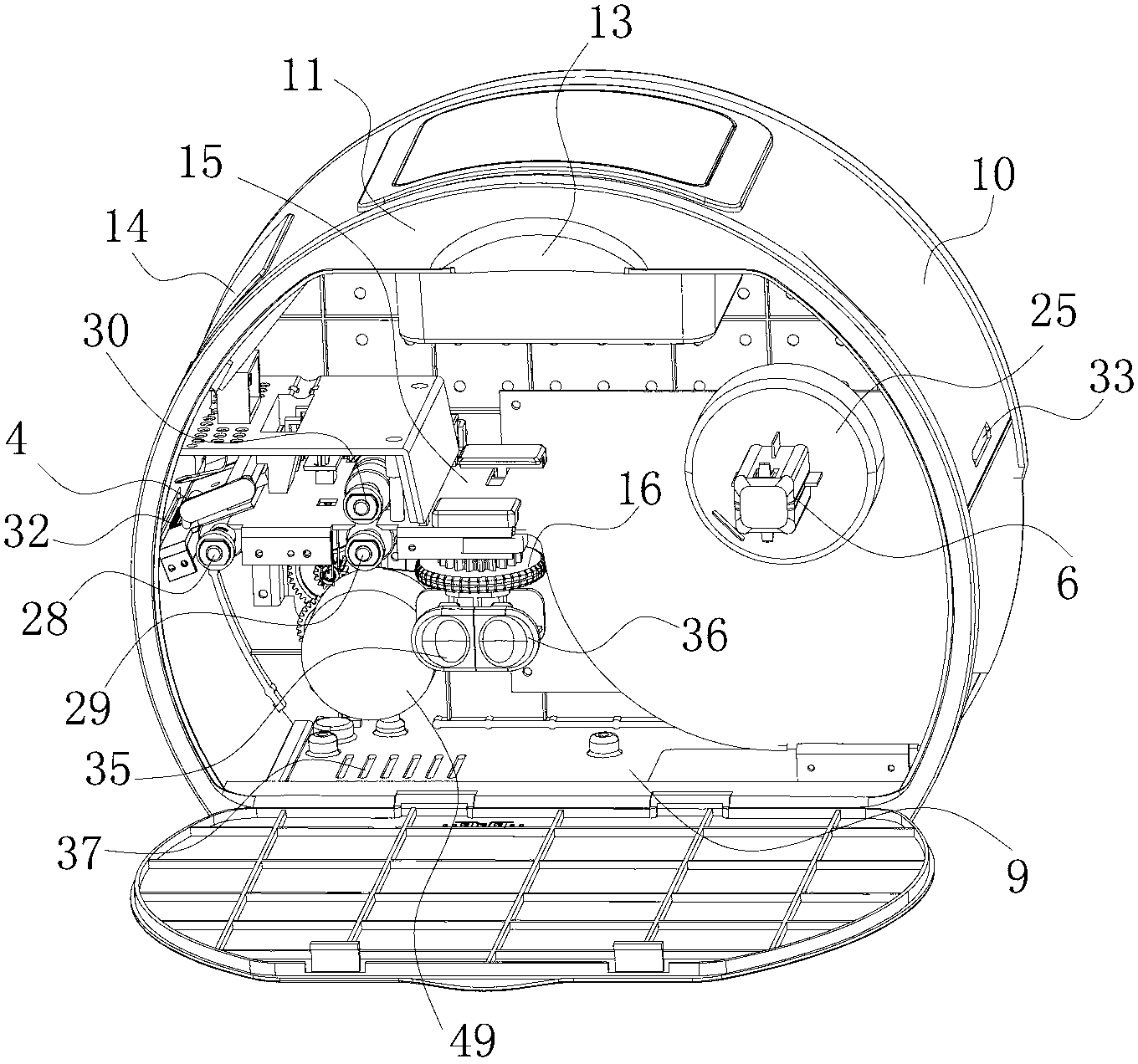

[0102] Such as Figure 1 to Figure 11As shown, a printer includes a housing 1, in which a paper roll placement chamber 2, a fixed frame 3 and a control circuit are arranged, the fixed frame 3 is provided with a print head 4, and the housing 1 is provided with a The paper outlet 5 corresponding to the print head 4, the reel 6 is arranged in the paper roll placement cavity 2, the operation control part 7 is arranged on the fixed frame 3, and the operation window is opened on the side of the casing 1. Cover plate 8 is arranged on it, and this cover plate 8 is adapted to the operation window. After the cover plate 8 is covered and operated to open the window, the cover plate 8 is opposite to the axial end of the reel 6, and the cover plate 8 covers the operation control part 7. live.

[0103] The housing 1 is in the shape of a sphere or an arc, and its bottom is a plane, and the center of the aforementi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com