Single-hydrophily single-prevention moisture absorption quickly dried fabric and production method thereof

A moisture-absorbing and quick-drying, production method technology, applied in the field of textile dyeing and finishing, can solve the problems of unsightly appearance and wearer's unpleasant feeling, and achieve the effect of good water and dirt repellent performance, good moisture absorption and quick-drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a single-parent single-proof, moisture-absorbing and quick-drying fabric, which is a 40S / 1100%cotton khaki double-sided Interlock single-parent single-proof, moisture-absorbing and quick-drying knitted fabric, and its production method includes the following steps:

[0034] Gray cloth-scouring-dyeing-soaping-fixation-drying-water-repellent printing (reverse)-baking-water-repellent coating (front)-baking-setting;

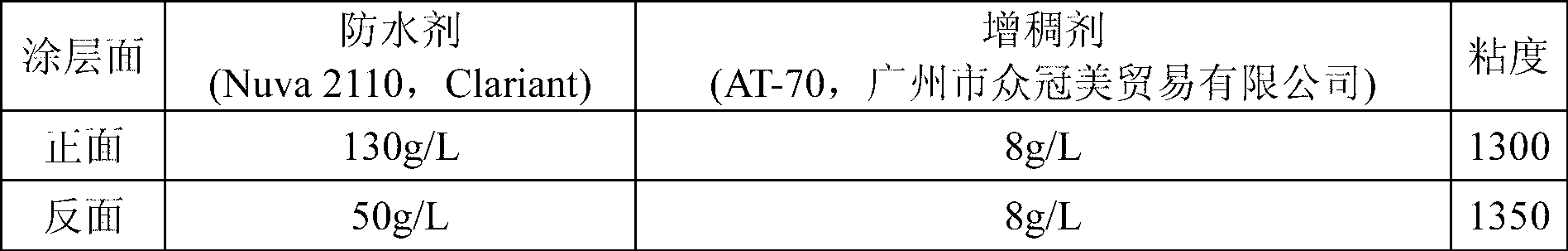

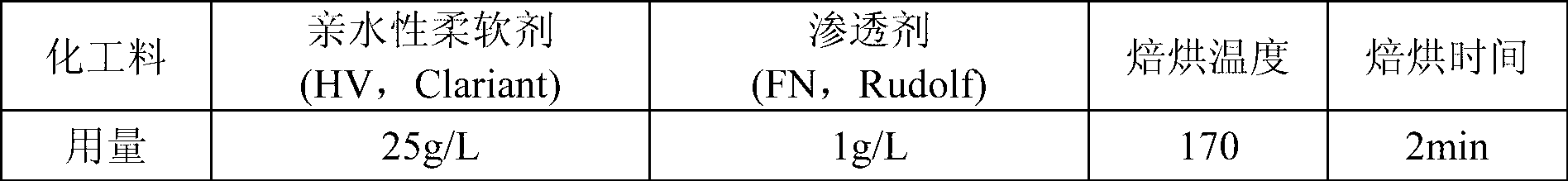

[0035] Among them, (1) scouring, dyeing, soaping, color fixing, drying, etc. are operated according to the conventional cotton dyeing process in the industry, and the scouring requirements are sufficient, and the fabric before coating must have good hydrophilicity; (2) Coating The water-repellent slurry used for printing and printing is prepared according to the composition given in Table 1 (the balance is water), and the various ingredients are mixed and stirred for 30 minutes with a mixer at a speed of 10000-15000r / min.

[0036] In t...

Embodiment 2

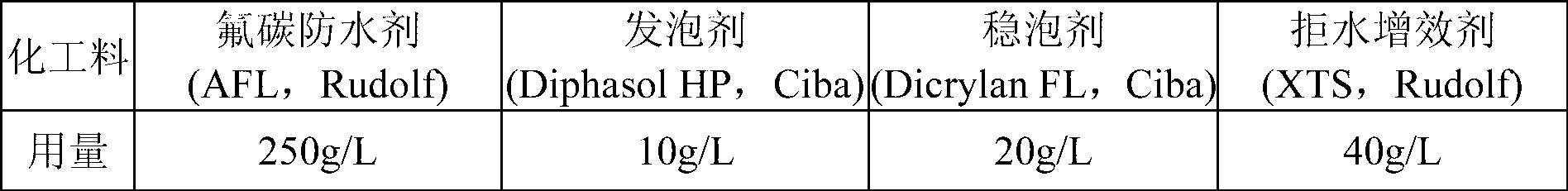

[0044] This embodiment provides a single-parent single-proof, moisture-absorbing and quick-drying fabric, which is a single-parent single-proof, moisture-absorbing and quick-drying fabric of 20S / 1 100% cotton pink single beads. The method of foam coating is adopted for the upper layer, and the method of foam printing is adopted for the water-repellent printing on the reverse side, and the water-repellent slurry is prepared according to the prescription provided in Table 4, and the rotary mesh foam coating and the rotary mesh foam are carried out according to the process parameters provided in Table 5. Printing, specifically as follows: first perform water-repellent printing on the back of the fabric, then bake at 150°C for 2 minutes, then apply water-repellent coating to the front of the fabric, and then bake at 150°C for 2 minutes. The process parameters of the shaping process are the same as those in Table 3. Through the above steps, the 20S / 1100% cotton pink single-pearl sin...

Embodiment 3

[0050] This embodiment provides a single-parent, single-proof, moisture-absorbing and quick-drying fabric, which is 40s×12s, 110×48, 180g / m 2 Single-parent single-proof, moisture-absorbing and quick-drying Oxford spinning fabric, its production method comprises the following steps:

[0051] Gray fabric - singeing - desizing - mercerizing - setting - preshrinking - water repellent printing (reverse) - baking - water repellent coating (front) - baking - setting;

[0052] Among them, (1) singeing, desizing, mercerizing, setting, pre-shrinking, etc. are all operated according to the conventional cotton dyeing process in the industry, and the setting requires hydrophilic soft oil to ensure that the fabric must have good hydrophilicity before coating; ( 2) The slurry for coating and printing is prepared according to the composition given in Table 6 (the balance is water). Mix the various components and stir with a mixer for 30 minutes at a speed of 10000-15000r / min. The prepared slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com