Intelligent bread machine and weighing control method thereof

A bread machine, intelligent technology, applied in non-electric variable control, control/regulation system, simultaneous control of multiple variables, etc., can solve the high requirements of flour ratio, high failure rate of bread making, and inability to complete bread making and other problems, to achieve the effect of low cost, intelligent bread making process and accurate weighing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

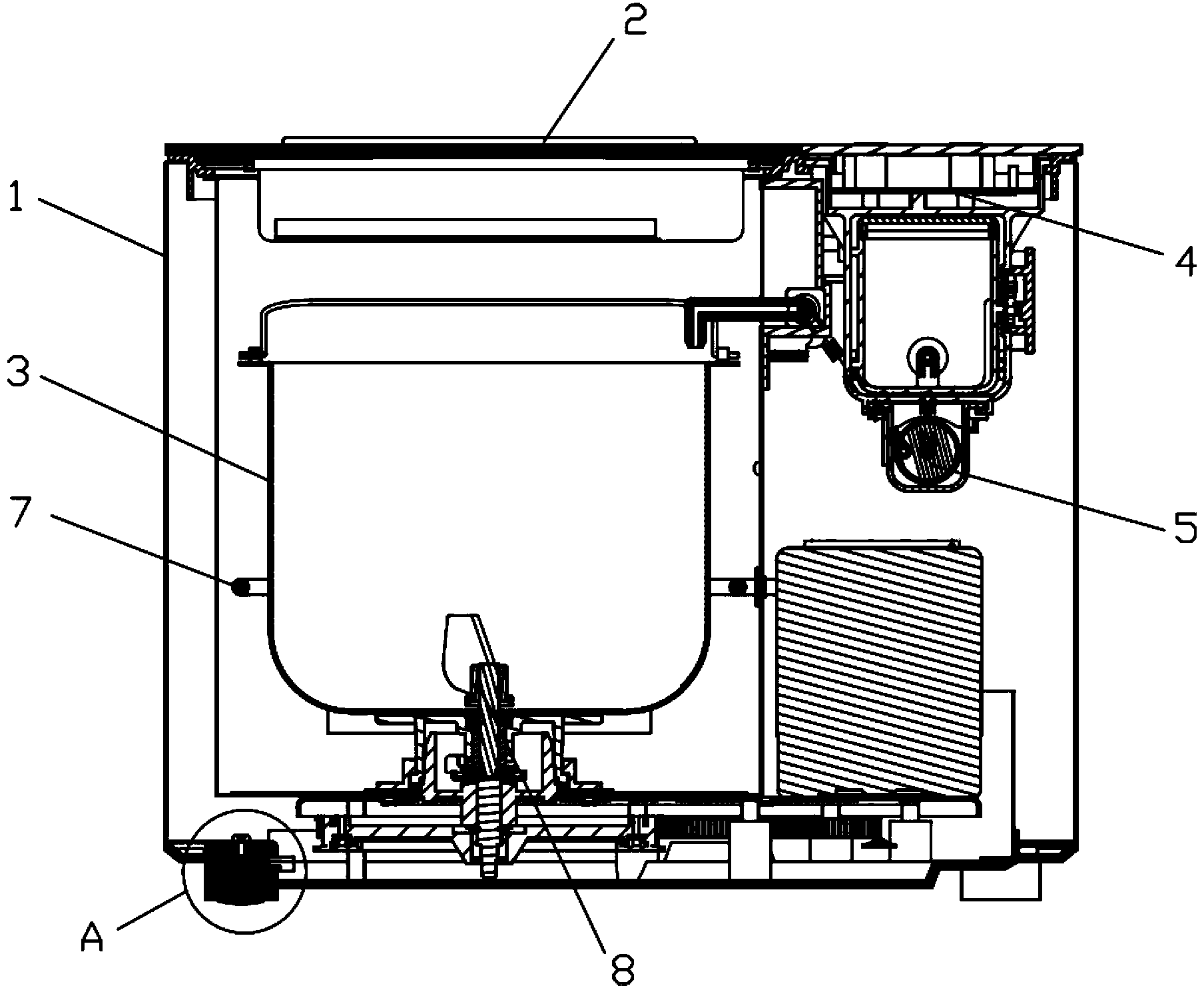

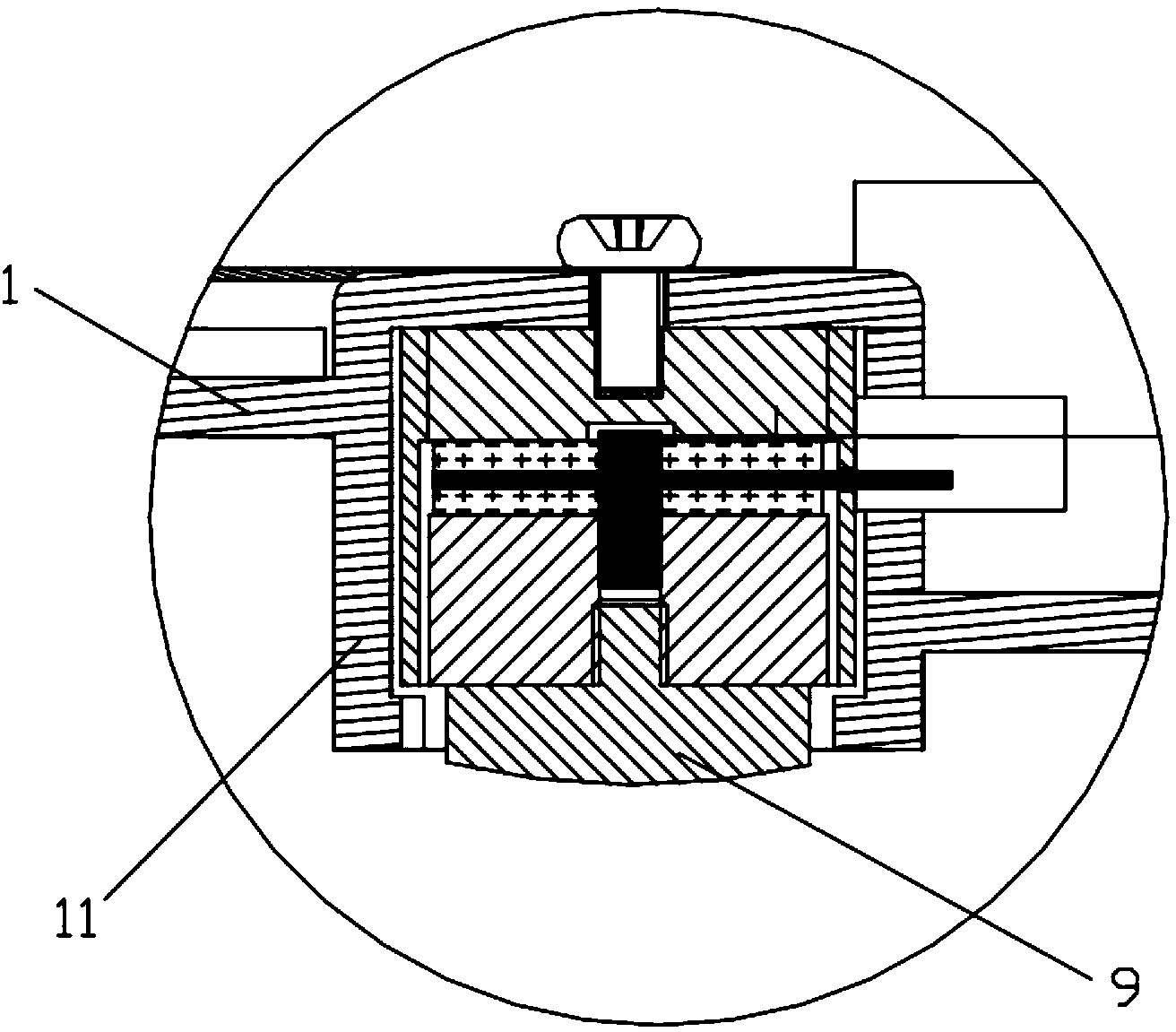

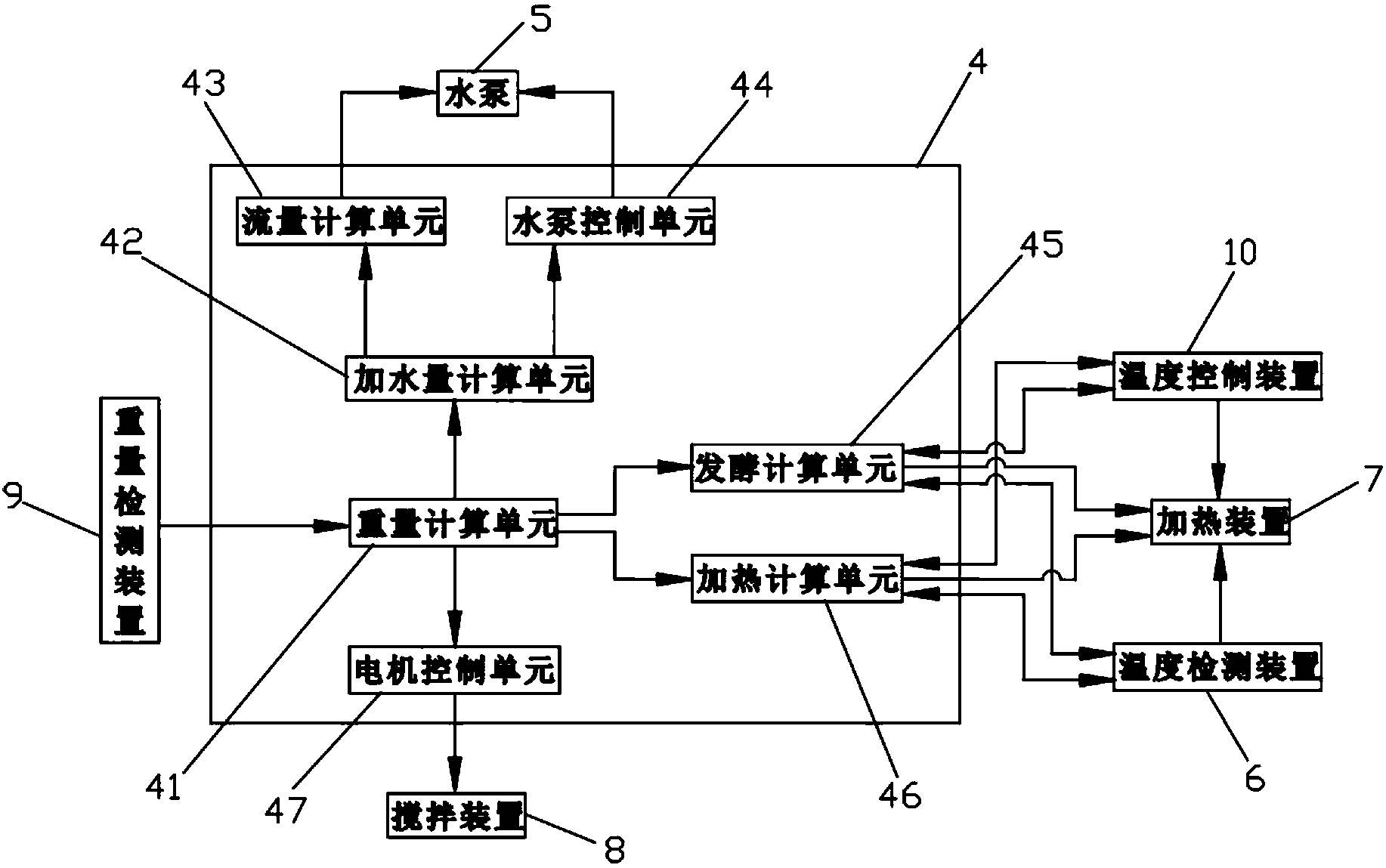

[0023] like Figure 1 to Figure 4 , an intelligent bread machine, comprising a body 1, a top cover 2, a bread bucket 3 and a main controller 4, the bottom of the body 1 is provided with feet 11, and the bread machine is provided with a water pump 5 electrically connected to the main controller 4, a temperature Detecting device 6, heating device 7 and stirring device 8, main controller 4 comprises the motor control unit 47 that connects stirring device 8, and described bread machine also comprises the weight acquisition device 9 that is arranged on body foot 11 places, and described weight acquisition The device 9 is used to collect the weight signal of the whole bread machine. The main controller 4 is provided with a weight calculation unit 41 electrically connected to the weight collection device 9. The weight calculation unit 41 calculates the weight before and after adding flour according to the collection result of the weight collection device 9. Difference. The weight ac...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the motor control unit 47 is electrically connected to the temperature detection device 6, and the temperature detection device 6 detects the temperature in the bread bucket 3 during the kneading stage, and controls the operation of the heating device 7 , to ensure that the temperature in the kneading stage is 28°C-32°C; and in this embodiment, the temperature detection device 6 is a temperature sensor, and the temperature sensor can be used to replace the temperature control device 10. The temperature sensor is used in the kneading stage, fermentation stage and During the baking stage, the temperature of the bread bucket is detected, and the detection signal is fed back to the corresponding motor control unit 47, fermentation calculation unit 45 and heating calculation unit 46, and each unit compares the detected temperature with the calculated temperature to control the work of the heating device 7. The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com