Method for determining ethylene glycol monomethyl ether, glycol ether, ethylene glycol ether acetate, glycol and diglycol in food wrap paper

A technology of ethylene glycol ethyl ether acetate and food packaging paper, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unknown detection, etc., and achieve easy promotion, satisfactory recovery rate and repeatability, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

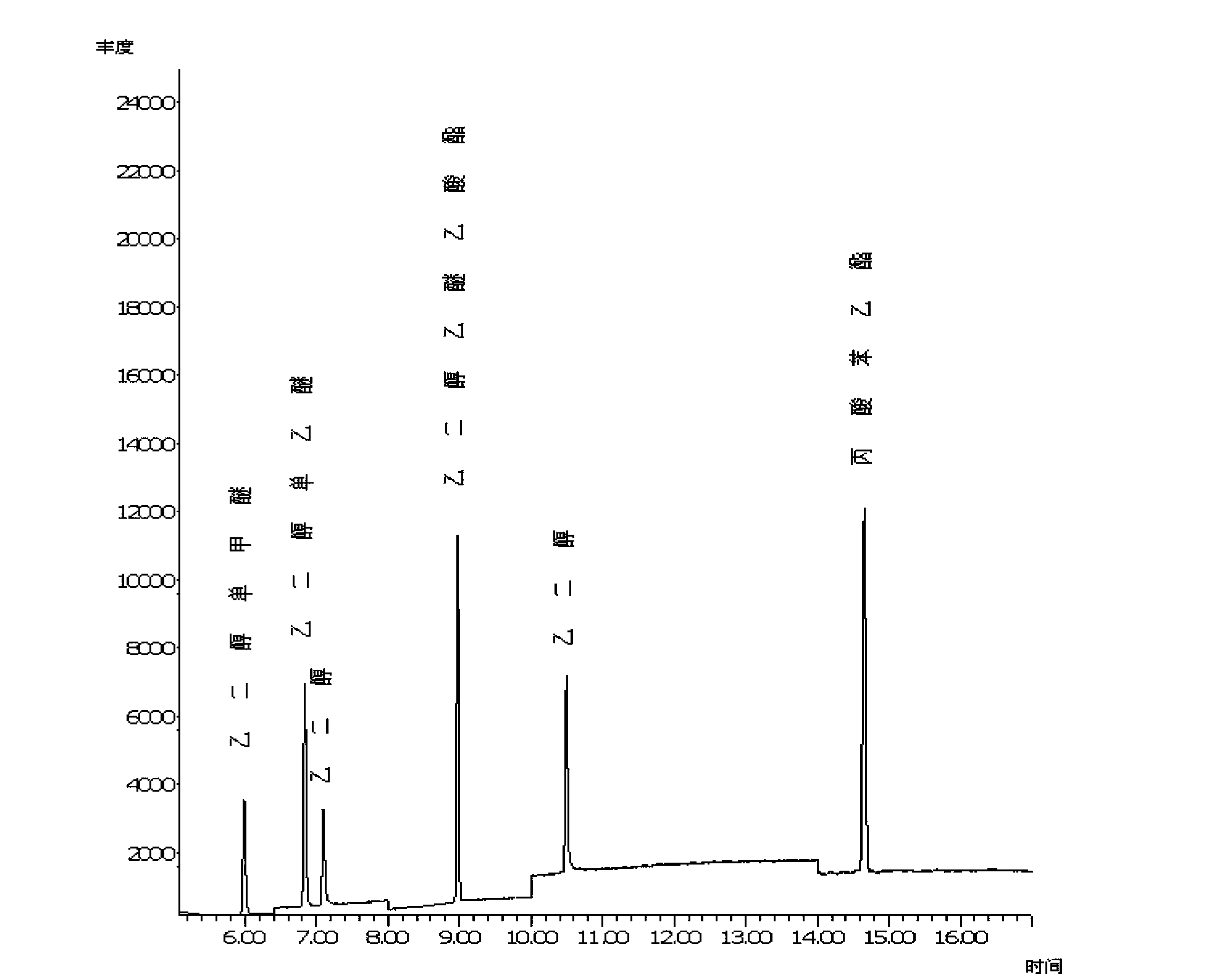

Image

Examples

Embodiment 1

[0055] A method for detecting ethylene glycol monomethyl ether, ethylene glycol monoethyl ether, ethylene glycol ethyl ether acetate, ethylene glycol, diethylene glycol in food packaging paper, specifically comprising the following steps:

[0056] 1) Take a sample of food wrapping paper, cut it into pieces no larger than 5mm×5mm, and mix them evenly;

[0057] 2) Accurately weigh about 0.5-1.0 g of the sample, place it in a 50-100 mL Erlenmeyer flask, add 10-20 mL of methanol extract with an internal standard concentration of 0.05 μg / mL, and conduct ultrasonic extraction at room temperature for 30 min;

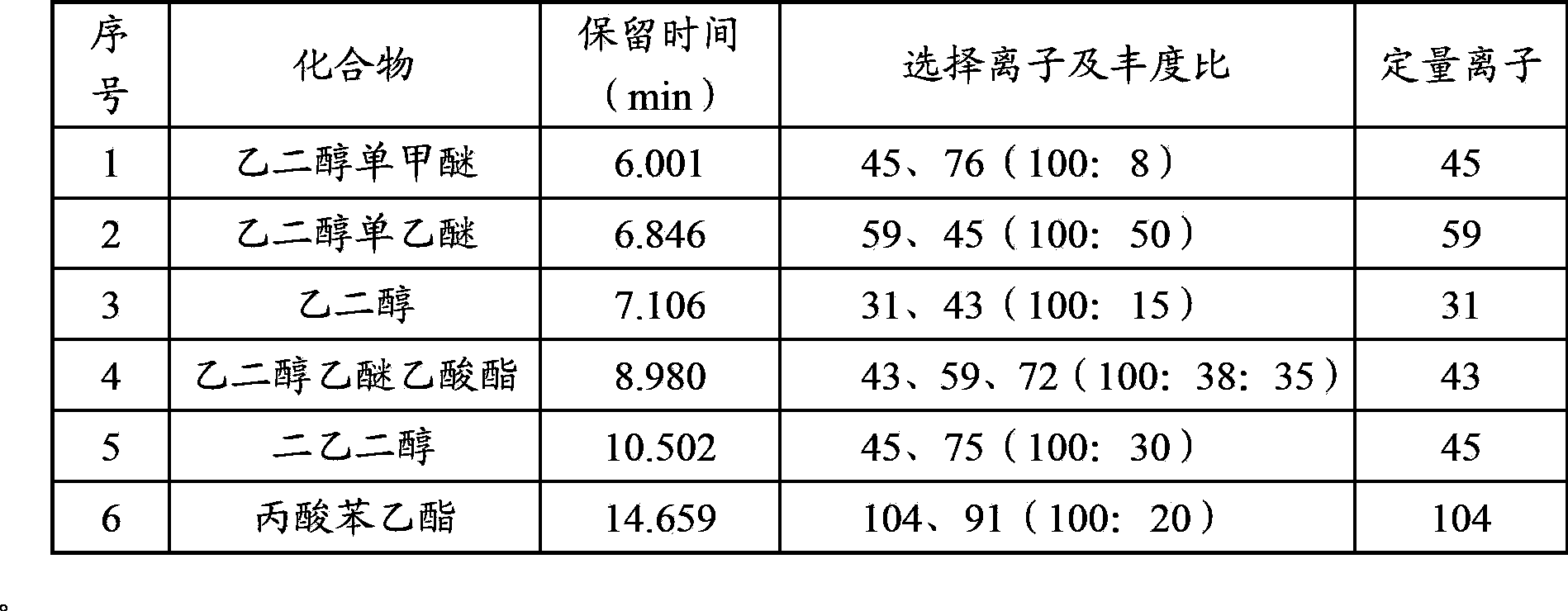

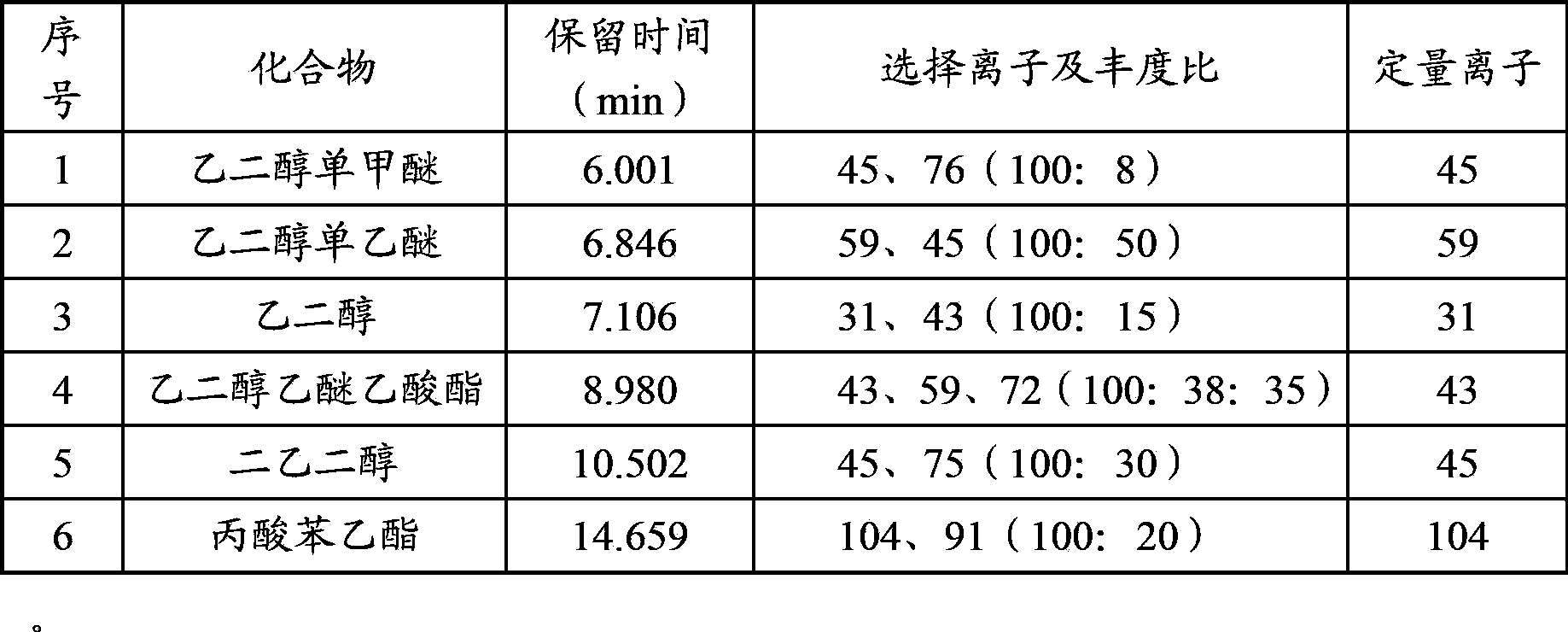

[0058] 3) The extract is filtered by a filter membrane and detected by gas chromatography / mass spectrometer:

[0059] DB-624 capillary chromatographic column (60m×0.32mm×1.80μm) was used for separation, the inlet temperature was 250°C, the injection volume was 1μL, the split ratio was 1:10, the column flow rate was 1mL / min, and the heating program was: 120°C hold 5min, rise to...

Embodiment 2

[0075] According to the method of Example 1, weigh 0.5g of the sample into a 50mL Erlenmeyer flask, add 10mL of the extract and sonicate for 30min, and then filter the extract through a 0.22μm organic phase membrane for measurement. A certain brand of food wrapping paper was tested three times a day for three consecutive days. The experimental results obtained are shown in Table 2 ethylene glycol repeatability test results and table 3 diethylene glycol repeatability test results.

[0076] Table 2 Ethylene glycol repeatability test results (mg / kg)

[0077]

[0078] Table 3 Diethylene glycol repeatability test results (mg / kg)

[0079]

[0080] It can be seen from Table 2 and Table 3 that the RSD of intraday repeatability is less than 5%, and the RSD of daytime repeatability is less than 4%, indicating that this method can accurately determine ethylene glycol monomethyl ether and ethylene glycol in food packaging paper. Contents of monoethyl ether, ethylene glycol ether ac...

Embodiment 3

[0082] According to the method of Example 1, weigh 1.0g of the sample in a 100mL Erlenmeyer flask, add 20mL of the extract and sonicate for 30min, and then measure the extract after being filtered through a 0.45 μm organic phase filter membrane to obtain ethylene glycol monomethyl ether, ethylene glycol Alcohol monoethyl ether, ethylene glycol ethyl ether acetate, ethylene glycol, diethylene glycol content of five substances. Accurately add five kinds of to-be-tested food packaging paper into a certain brand of food wrapping paper with known content of five substances: The mixed standard samples of the components were used to measure the content values of the five components to be measured under the three spiked levels of low, medium and high. Three samples were measured in parallel for each level, and the average value was used to calculate the recovery rate of standard addition. The test results are shown in Table 7 for the recovery experimental results of the five compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com