Self-lubricating structure of oil pump

An oil pump and self-lubricating technology, which is applied in the direction of pressure lubrication of the lubricating pump, can solve the problems of increased wear, scrapping of the engine, and pulling of the engine, and achieves a good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0036] The key points of this embodiment are as follows:

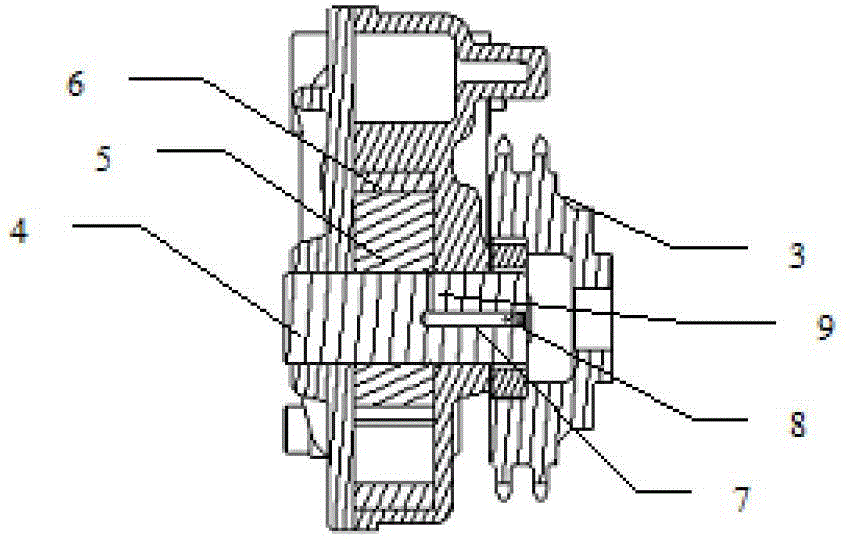

[0037] 1. The rotor shaft of the oil pump is in interference fit with the inner rotor, and 3 grooves are evenly distributed around the inner rotor.

[0038] 2. An annular oil storage tank is distributed radially inside the rotor shaft connected with the sprocket.

[0039] 3. The lubricating oil in the annular oil storage tank of the rotor shaft reliably pressure-lubricates the sprockets.

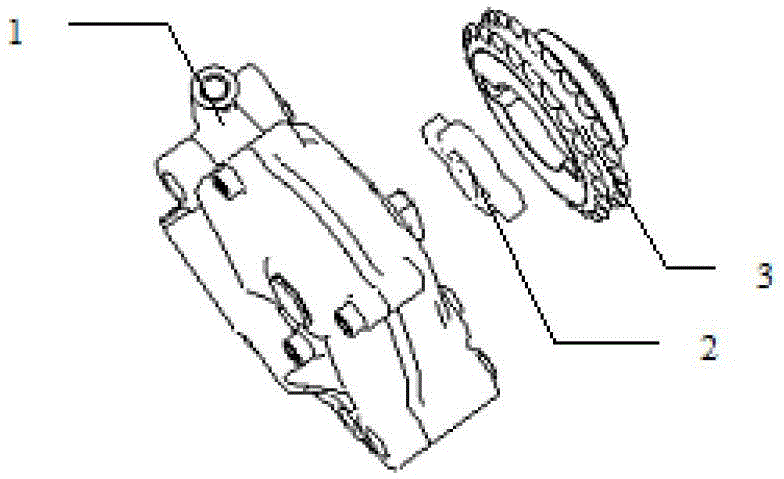

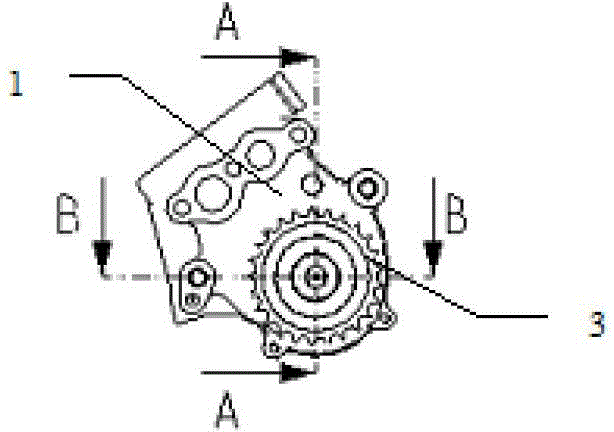

[0040] With reference to the accompanying drawings, the present embodiment is a rotor type oil pump, mainly composed of an oil pump body (1), an oil pump shaft (4), an inner rotor (5), an outer rotor (6) and the like. The drive of the oil pump shaft (4) and the sprocket (3) is transmitted through the cross key (2).

[0041] At present, relia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com