Direct-reading examining seal instrument suitable for eccentric water distributor

An eccentric water distribution and sealing instrument technology, applied in the fields of fluid production, measurement, wellbore/well components, etc., can solve the problems of low efficiency, inability to measure, poor real-time performance, etc., to reduce wear, reduce labor intensity, and improve sealing The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

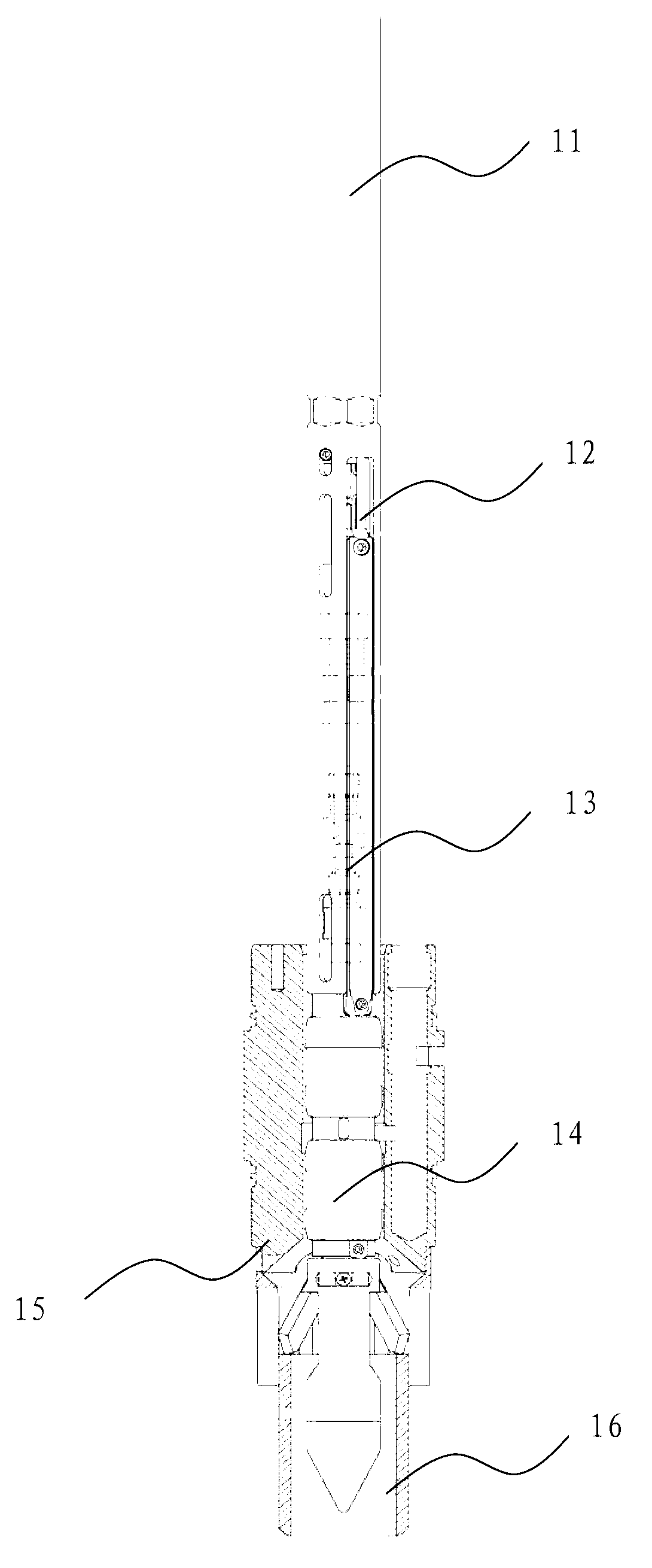

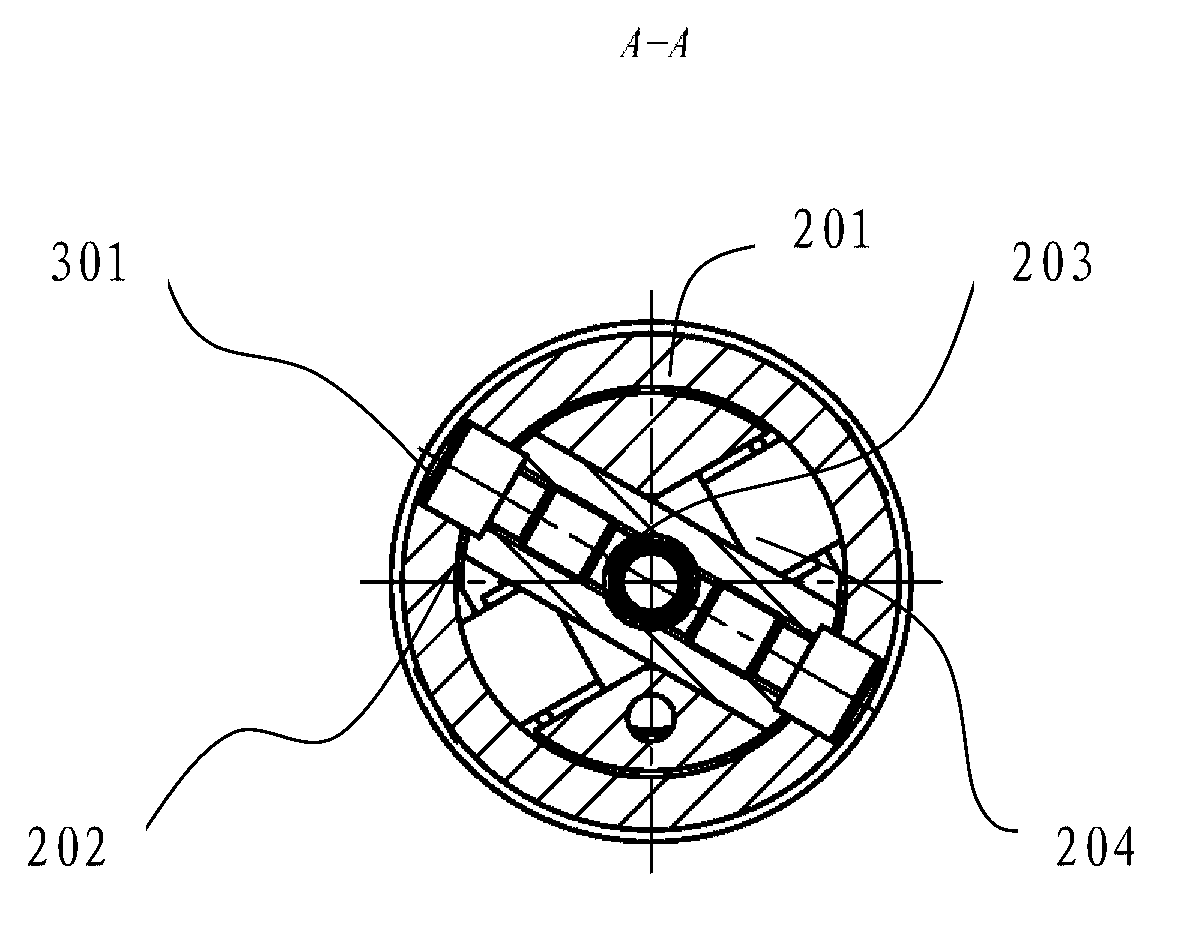

[0022] The invention provides a direct-reading seal tester suitable for eccentric water distributors, including a seal tester skeleton, a direct-reading pressure measurement part 13, a controllable sealing nipple 14, a controllable positioning nipple 16 and a , the control part of the positioning nipple action; the controllable sealing nipple 14 is provided with a pressure measurement channel connected with the formation and a pressure relief channel for unsealing; the control part includes a sealing, positioning control device, a magnetic positioning control device, and The upper computer communication module; the control components are respectively connected with the controllable sealing pup joint and the controllable positioning pup joint and drive the controllable sealing pup joint and the controllable positioning pup joint to work.

[0023] The control components include a motor, a thrust rod, a connecting cylinder set outside the frame of the seal tester, and a threaded r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com