Method for simultaneously extracting multiple effective components from bitter almond

A technology for active ingredients and bitter almonds, which is applied in the field of simultaneously extracting multiple active ingredients from bitter almonds, can solve the problems of increasing the cost of bitter almonds, waste of resources, single extraction, etc., so as to improve the comprehensive utilization rate, avoid resource waste, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

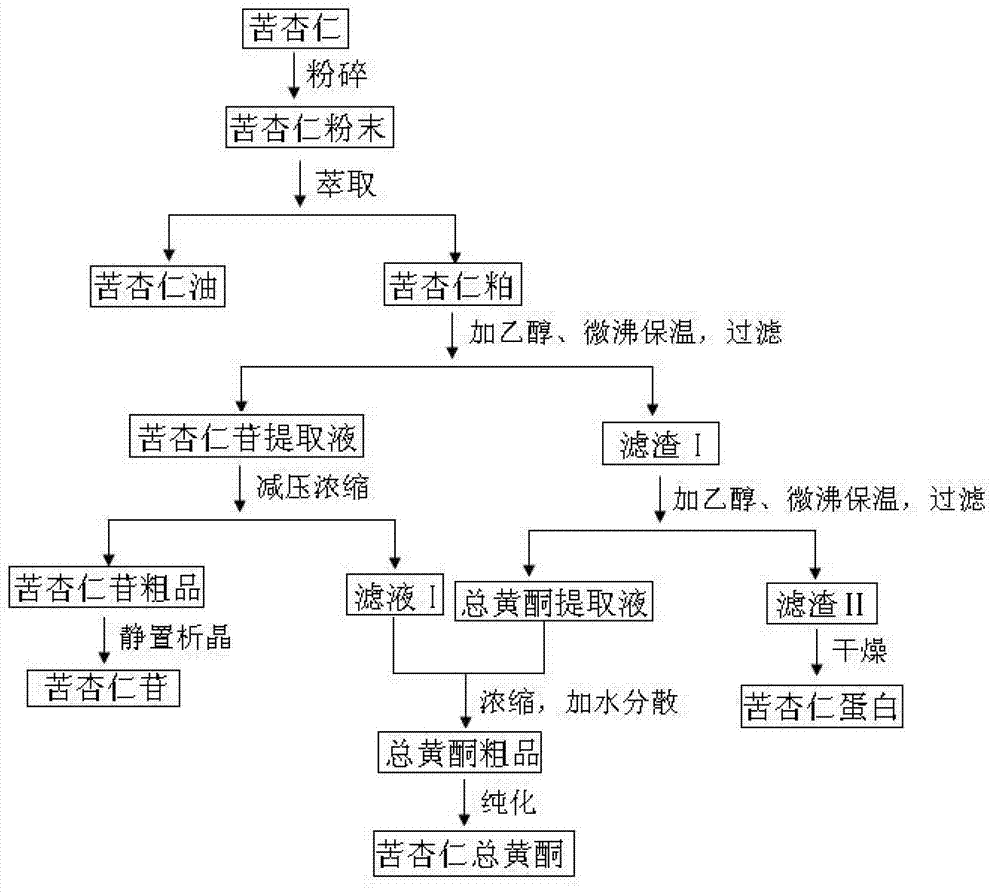

[0026] A method for simultaneously extracting and separating bitter almond oil, amygdalin, total flavonoids of bitter almonds and amygdalin from bitter almonds, comprising the following steps:

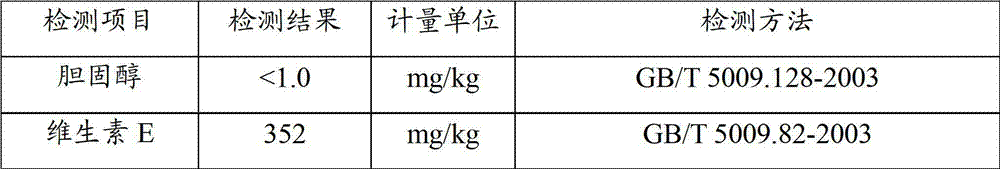

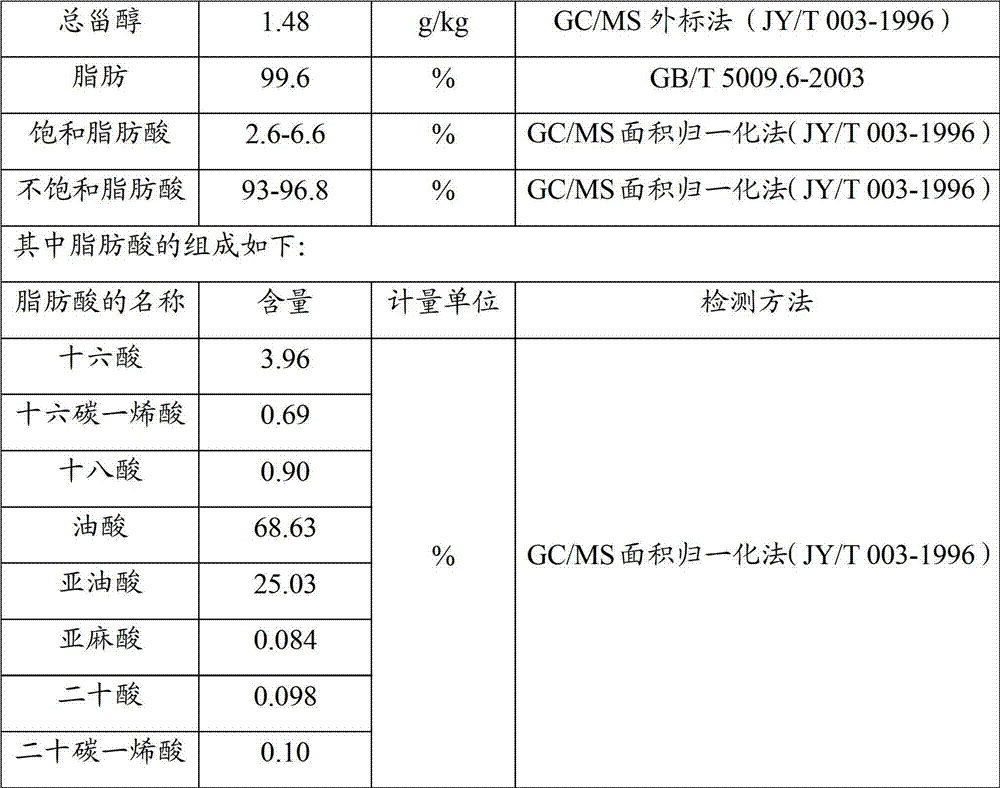

[0027] (1) Bitter almond oil extraction: select 100 g of fresh raw bitter almonds, crush them to 10-120 mesh, and extract bitter almond oil from bitter almonds by supercritical fluid extraction. The specific process is: the supercritical fluid extraction device includes extraction kettle, separation kettle Ⅰ, separation kettle Ⅱ, carbon dioxide gas storage tank, high-pressure pump, and the crushed bitter almonds are placed in the extraction kettle of the supercritical fluid extraction device. The temperature of the separation kettle Ⅰ is 30 ° C, and the temperature of the extraction kettle is 35 Under the condition of ℃, open the carbon dioxide storage tank and pressurize the extraction kettle. When the pressure of the extraction kettle reaches 30MPa and the flow rate of carbon dioxide ...

Embodiment 2

[0033] A method for simultaneously extracting and separating bitter almond oil, amygdalin, total flavonoids of bitter almonds and amygdalin from bitter almonds, comprising the following steps:

[0034] (1) Extract bitter almond oil: select 1 kg of fresh raw bitter almonds, grind them to 10-120 mesh, and extract bitter almond oil from bitter almonds by supercritical fluid extraction. The specific process is: the supercritical fluid extraction device includes extraction kettle, separation kettle Ⅰ, separation kettle Ⅱ, carbon dioxide gas storage tank, high-pressure pump, put the crushed bitter almonds in the extraction kettle of the supercritical fluid extraction device, the temperature in the separation kettle Ⅰ is 45 ℃, and the temperature of the extraction kettle is 45 Under the condition of ℃, open the carbon dioxide storage tank and pressurize the extraction kettle. When the pressure of the extraction kettle reaches 32MPa and the flow rate of carbon dioxide is 12L / h, keep th...

Embodiment 3

[0040] A method for simultaneously extracting and separating bitter almond oil, amygdalin, total flavonoids and amygdalin from bitter almonds, comprising the following steps:

[0041] (1) Bitter almond oil extraction: select 100 g of fresh raw bitter almonds, crush them to 10-120 mesh, and extract bitter almond oil from bitter almonds by supercritical fluid extraction. The specific process is: the supercritical fluid extraction device includes extraction kettle, separation kettle Ⅰ, separation kettle Ⅱ, carbon dioxide gas storage tank, high-pressure pump, and the crushed bitter almonds are placed in the extraction kettle of the supercritical fluid extraction device. Under the condition of ℃, open the carbon dioxide storage tank and pressurize the extraction kettle. When the pressure of the extraction kettle reaches 25MPa and the flow rate of carbon dioxide is 24L / h, keep the temperature and pressure, extract for 2 hours, and collect the extract to obtain bitter almond oil. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com