Bolt distribution device

A dispensing device and bolt technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that cannot meet the requirements of flow, fast and automatic production, affect the work efficiency of manufacturing products, increase the input of labor costs, etc., and achieve simple structure, Wide range of applications and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

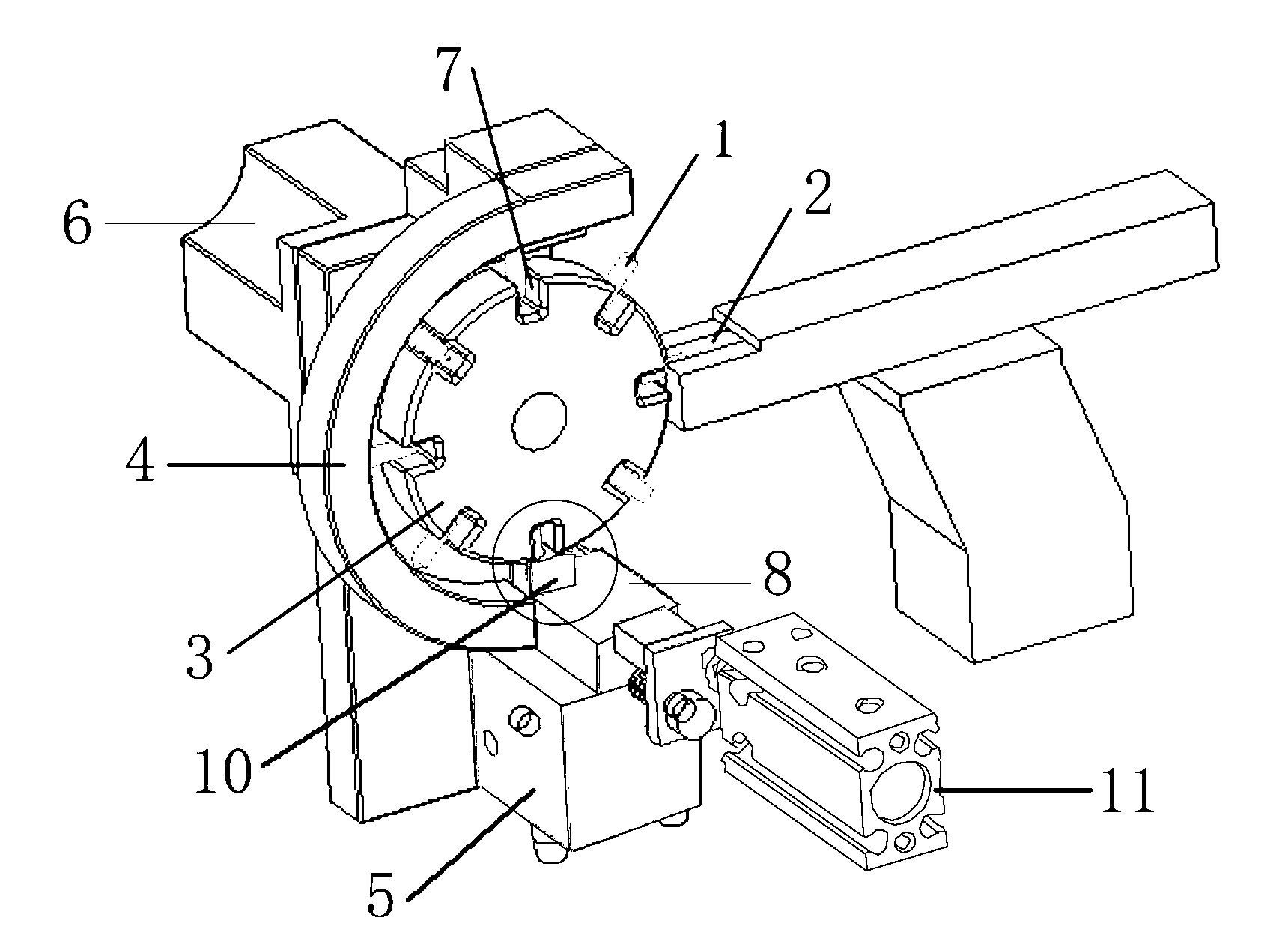

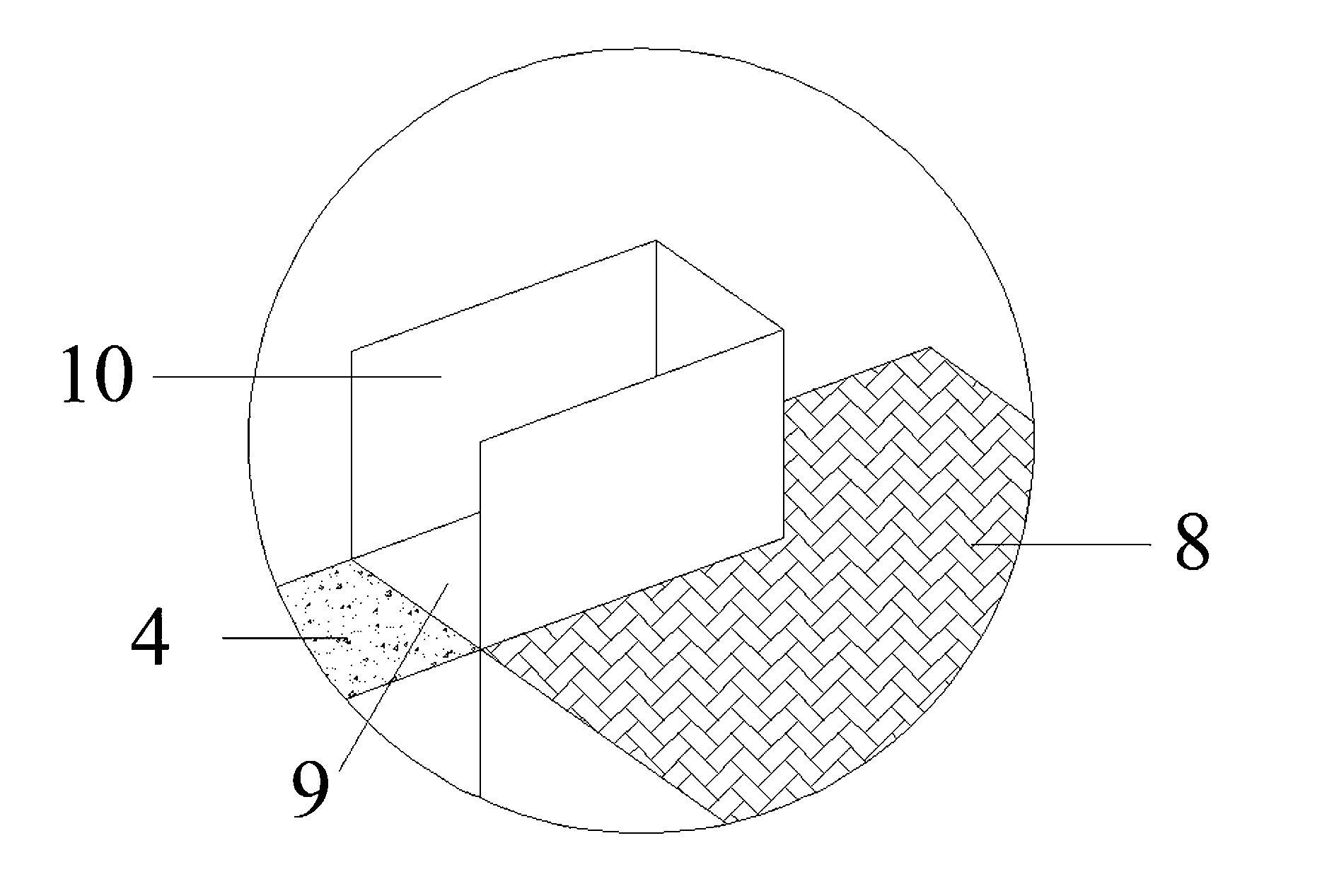

[0016] refer to figure 1 with image 3 , The bolt distributing device of the present invention includes: a feeding channel 2 , a distributing plate 3 , a limit sleeve 4 , a distributing box 5 and a motor 6 . The specific instructions are as follows:

[0017] The delivery channel 2 is used to send the bolt 1 to the distribution plate 3, and the distribution plate 3 can only receive one bolt 1 at a time, so the radial dimension of the inner diameter of the delivery channel 2 should not be too large, slightly larger than the diameter of the bolt 1 That is enough, but it cannot be longer than the length of the bolt 1, so as to ensure that each bolt 1 moves along its own axial direction in the delivery channel 2. In order to make the bolt 1 be sent smoothly into the distribution plate 3, it is advisable to set the delivery channel 2 horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com