A grasping and positioning device and method

A technology of grasping and positioning, and the other side, which is applied in the directions of packaging, packaging protection, transportation and packaging, etc., can solve the problems of sorting more or less food, high labor intensity of workers, and low production efficiency, so as to solve the problem of unsatisfactory sorting. Neat, simple structure, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

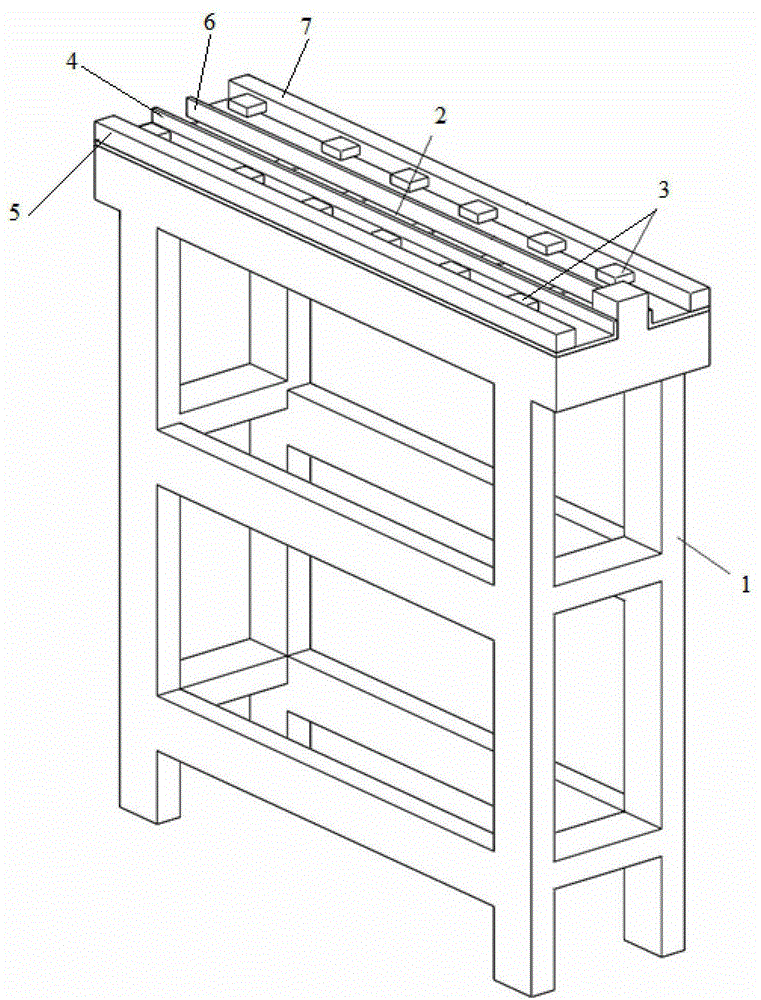

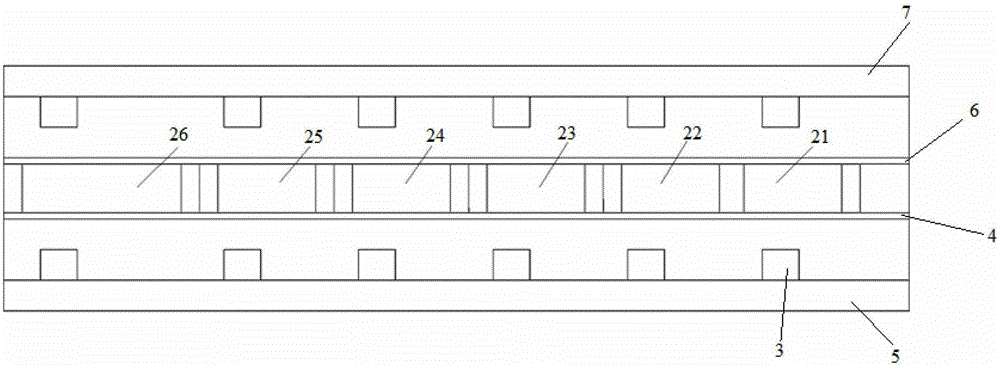

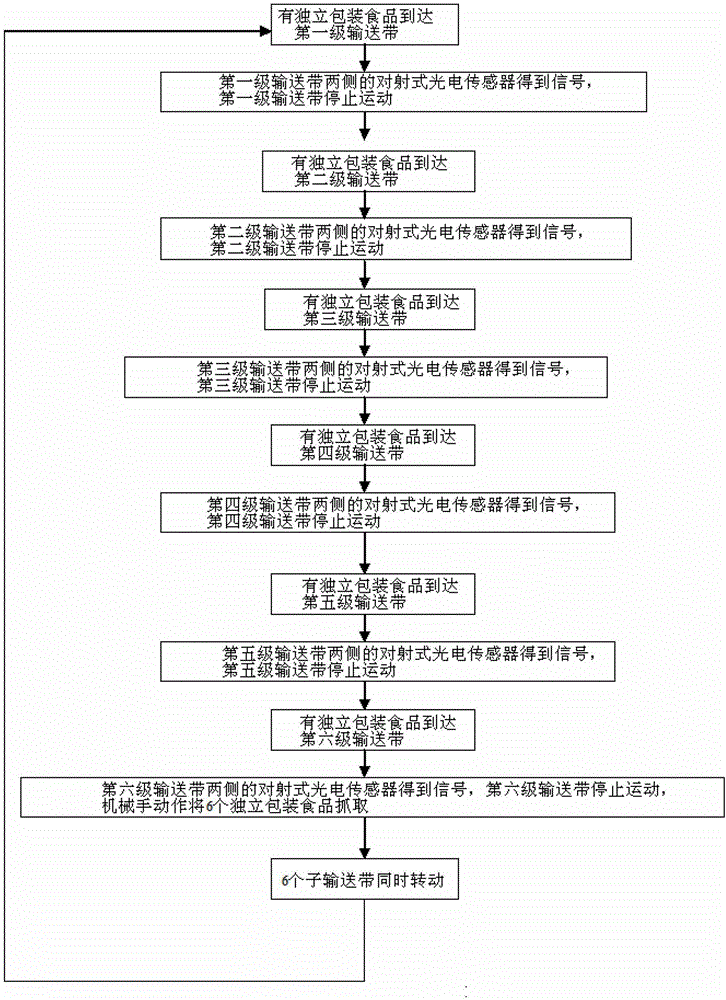

[0028] Such as figure 1 , 2 As shown, the present invention provides a kind of grasping positioning device, comprises controller, frame 1 and the grading conveyor belt 2 that is arranged on frame 1, and grading conveyor belt 2 comprises two or more than two sub-conveyor belts, in this In the embodiment, six sub-conveyor belts are taken as an example for description. The transmission direction of each sub-conveyor belt is consistent, and along the transmission direction are the first-level conveyor belt 21, the second-level conveyor belt 22, the third-level conveyor belt 23, the fourth-level conveyor belt 24, the fifth-level conveyor belt 25 and the first-level conveyor belt. Six-stage conveyor belt 26. The length of the first stage conveyor belt 21, the second stage conveyor belt 22, the third stage conveyor belt 23, the fourth stage conveyor belt 24 and the fifth stage conveyor belt 25 is equal to the length of an independently packaged food to be positioned, the sixth stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com