Valve assembly for a trailer braking assembly

A technology of parking brake and valve assembly, applied in the direction of brake assembly, brake, vehicle parts, etc., can solve the problems of sliding guide, complicated operation of switching valve, large installation space, etc., so as to improve work safety and reliable operation mode. , the effect of simple manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

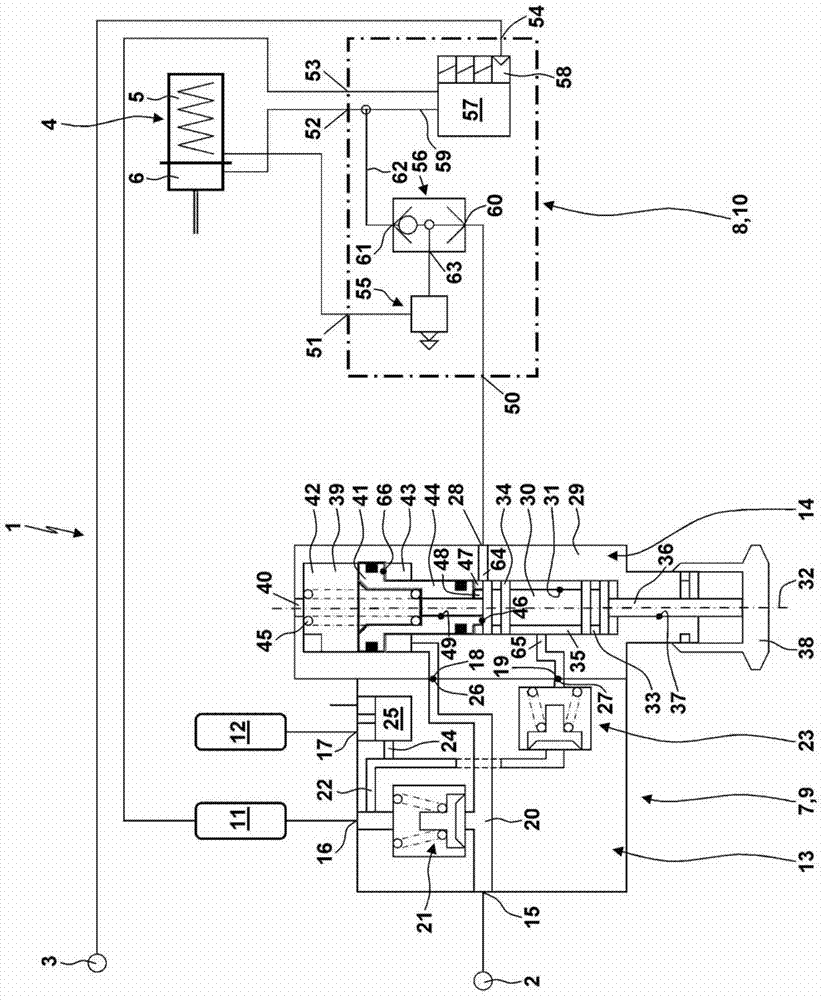

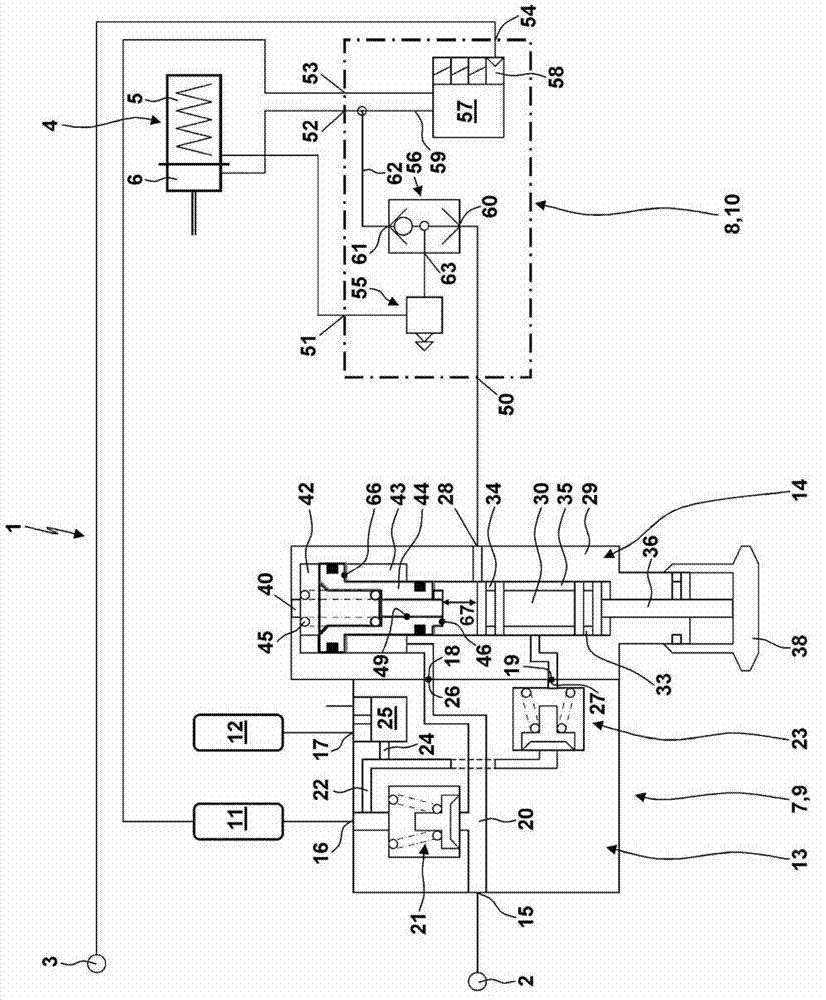

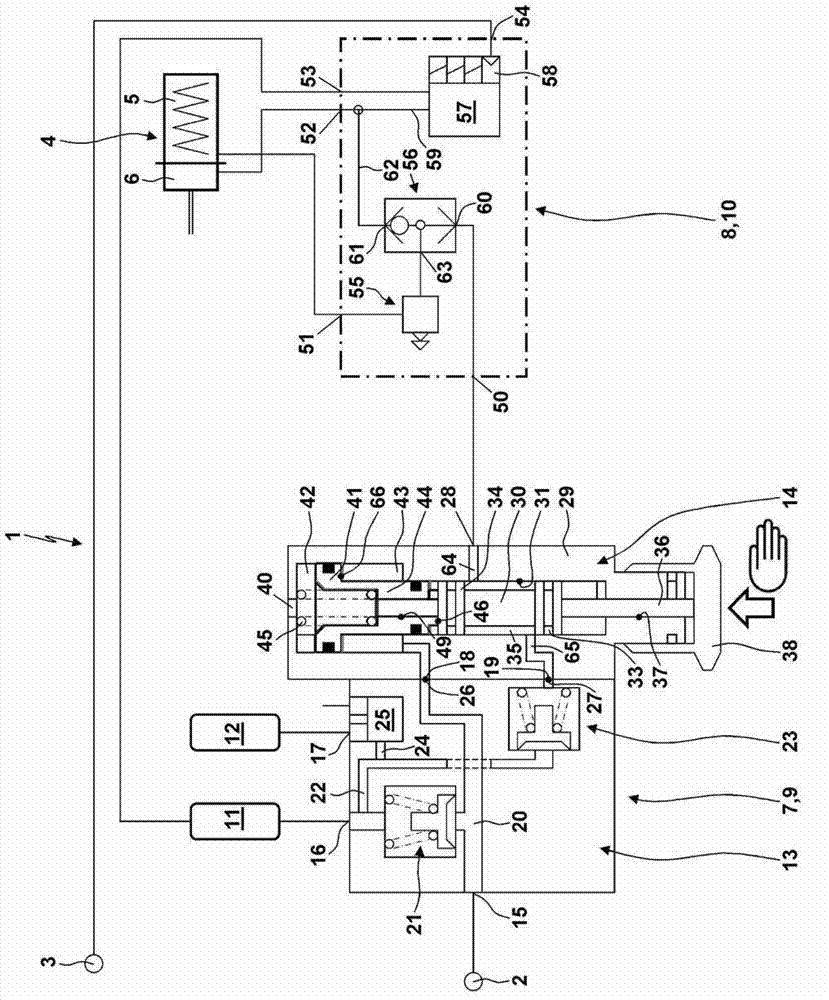

[0040] figure 1 A trailer brake system 1 of a commercial vehicle is shown schematically. The trailer equipped with the trailer braking system 1 together with the tractor forms a vehicle group. The pneumatic coupling between the trailer and the tractor takes place via the accumulator coupling (Kupplungskopf Vorrat) 2 and the brake coupling (Kupplungskopf Bremse) 3 via which the trailer brake system 1 is fed supply pressure by the tractor, via The brake coupling supplies the trailer brake system 1 with a brake control pressure which is associated with the driver's actuation of the brake pedal of the tractor. The trailer brake system 1 is equipped with a spring accumulator, a parking brake 5 and a service brake 6 at least on several axles with a combined brake cylinder 4 . It is understood that the trailer brake system 1 generally has more than one combined brake cylinder 4 shown, wherein the axle can also be equipped with only a service brake 6 and / or a spring accumulator park...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com